New-type core ear-picking roller

A technology for picking ear rollers and corn, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of easy slippage of corn stalks, increased corn loss rate, easy to break corn stalks, etc. The effect of increased corn yield and reliable corn stalks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

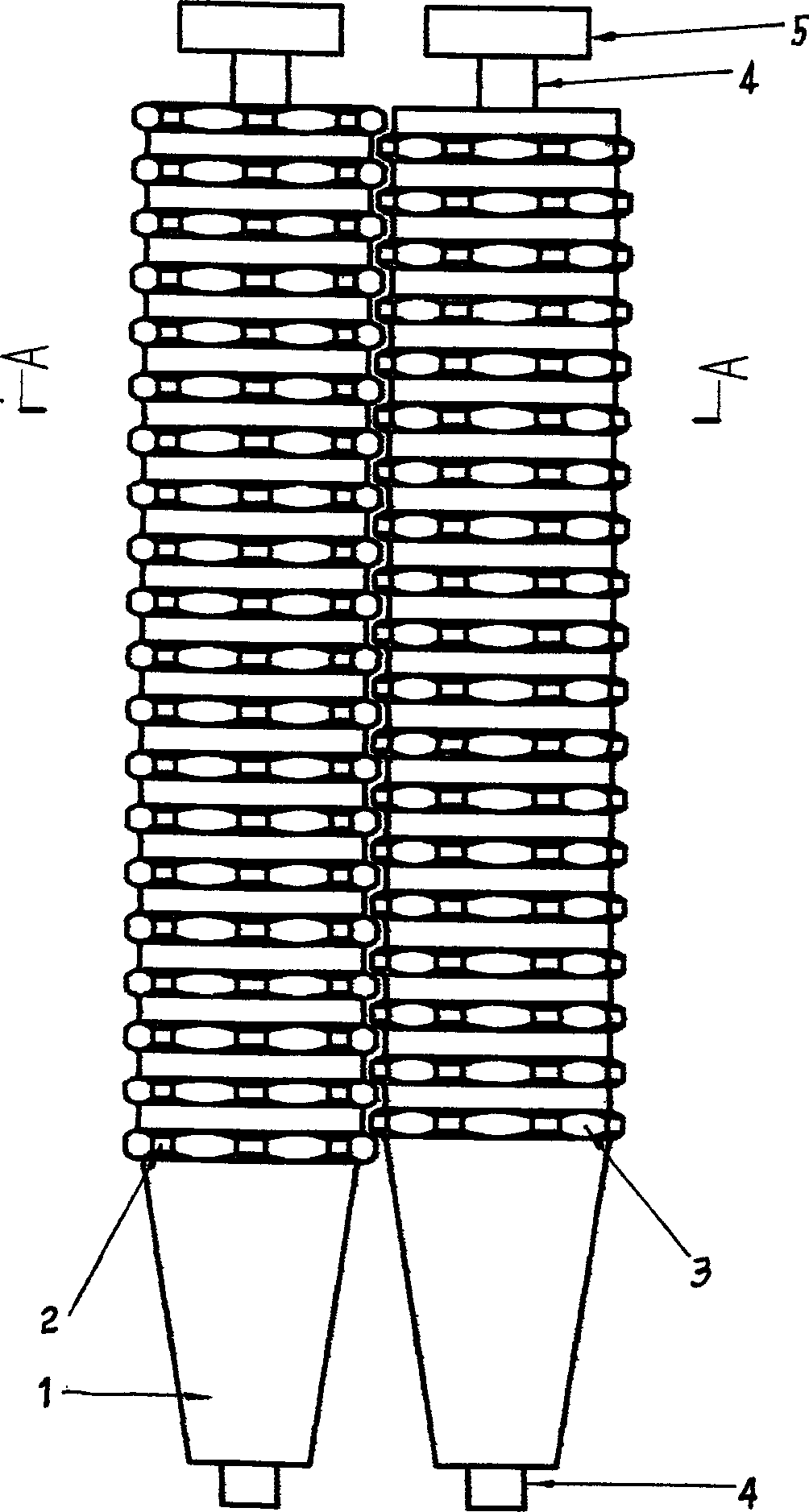

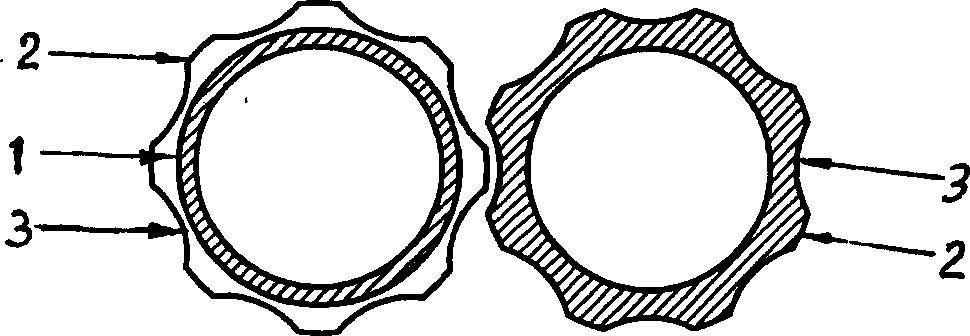

[0014] Embodiment 1. New type corn picking roller

[0015] The concrete structure of the novel corn picking roller of this example is by figure 1 and figure 2 Jointly shown. This novel corn ear removal roller 1 of this example, structural feature is: the roller surface of this novel corn ear removal roller 1 is provided with the tooth-like structure that is used for ear removal, and concrete structure is: the roller cylinder surface of each ear removal roller is uniform There are matrix column-shaped convex teeth 2 with 40 rows in the axial direction and 8 columns in the radial direction, and at the same time, evenly distributed matrix column-shaped concave teeth 3 with 40 rows in the axial direction and 8 columns in the radial direction are formed. The so-called uniform distribution means that these convex teeth 2. The concave teeth 3 are uniform in size, shape, and degree of convexity and concaveness. When it is used on a corn harvester, it is arranged in pairs on the fr...

Embodiment 2

[0016] Embodiment 2. Novel corn picking roller

[0017] The concrete structure of the novel corn picking roller of this example is by figure 1 and figure 2 Jointly shown. In this example, the surface of the new corn picking roller 1 is provided with tooth-shaped teeth for picking ears. 2. At the same time, uniformly distributed axial 99 rows×radial 15 column-shaped concave teeth 3 are formed. All the convex and concave teeth 2 and 3 of the new corn ear picking roller must be aligned and installed to form the corn ear picking mouth. All the other things not described are the same as those described in Example 1, and will not be repeated.

Embodiment 3

[0018] Embodiment 3. Novel corn picking roller

[0019] The concrete structure of the novel corn picking roller of this example is by figure 1 and figure 2 Jointly shown. In this example, the surface of the new-type corn picking roller 1 is equipped with teeth for picking ears. 2. At the same time, evenly distributed axial rows of 20 rows × 5 columns in the radial direction are formed. All the convex and concave teeth 2 and 3 of the new corn ear picking rollers must be aligned and installed to form the corn ear picking mouth. All the other undescribed are the same as those described in Embodiment 1 and Embodiment 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com