Dual-body small waterline surface hydrofoil composite high-speed ship

A small waterplane, composite technology, applied in the direction of hull, ship construction, hydrodynamic characteristics/hydrostatic characteristics, etc. The effect of small wet surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

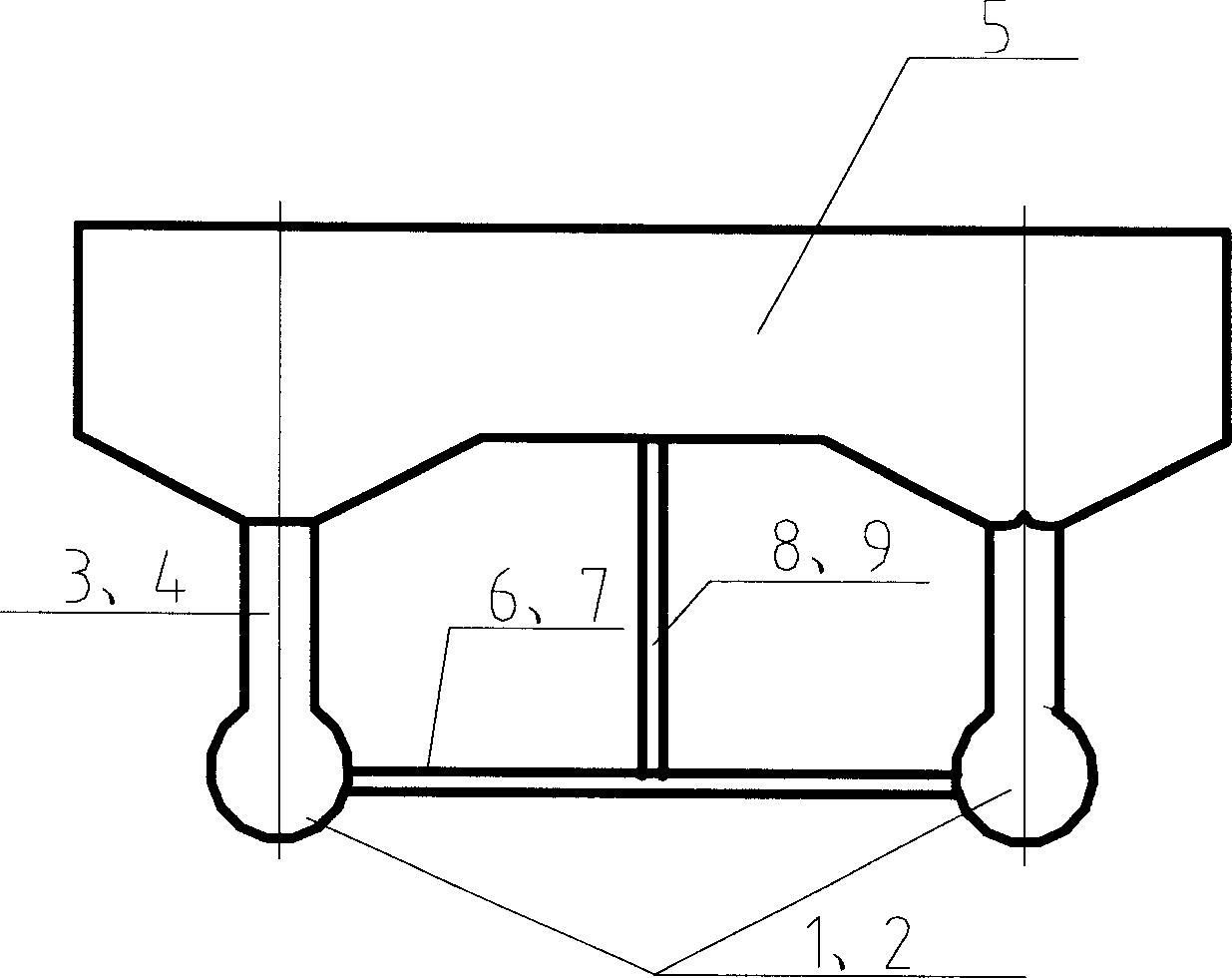

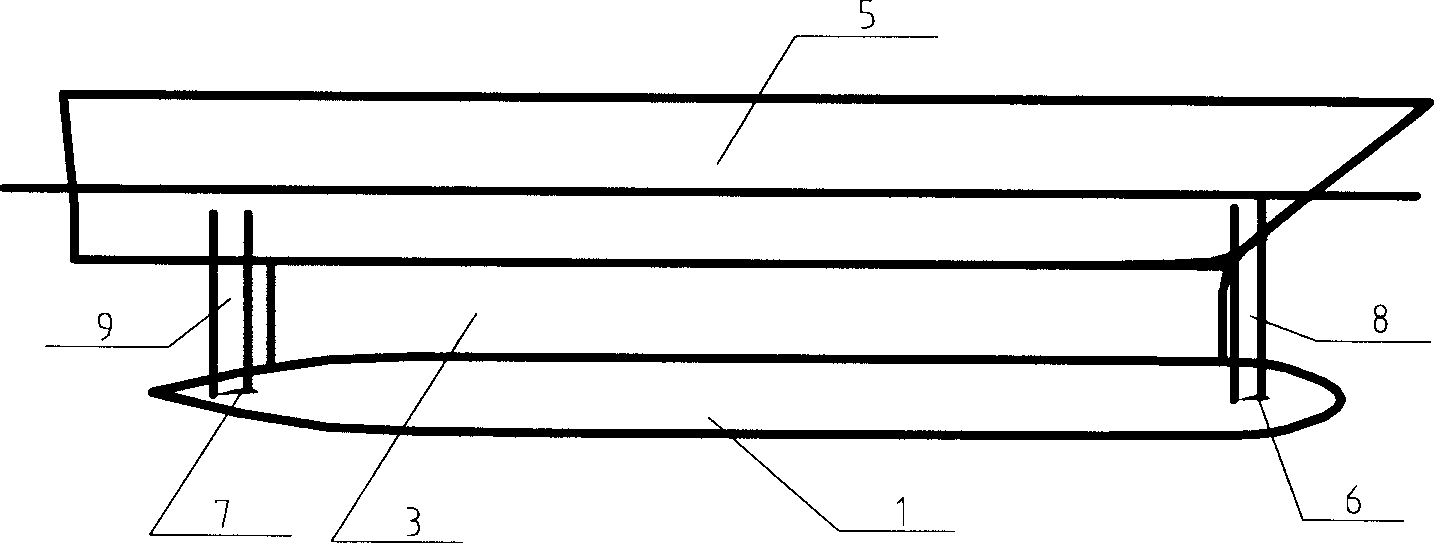

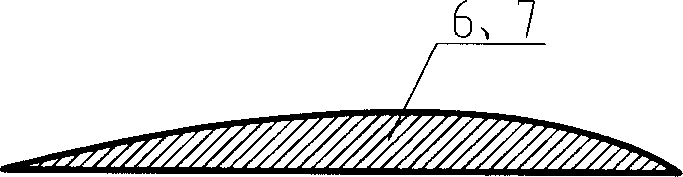

[0018] Such as figure 1 with 2 As shown, the present invention includes: the lower body 1, 2 of the left and right sides of the catamaran, the pillars 3, 4, the connecting bridge 5, the front and rear hydrofoil 6, 7 and the front and rear hydrofoil pillars 8,9. The lower bodies 1 and 2 of the left and right sides of the catamaran are respectively connected by slender struts 3 and 4 and the connecting bridge 5 on the upper part of the hull. At the same time, the lower bodies 1 and 2 of the left and right sides of the catamaran The front and rear hydrofoils 6 and 7 are arranged front and rear, and the front and rear hydrofoils 6 and 7 are respectively provided with front and rear hydrofoil pillars 8 and 9 connected to the connecting bridge 5.

[0019] The lower main bodies 1, 2 of the two left and right lamellas of the catamaran are two slender bodies with circular or elliptical cross-sections. There are an inflow section, a parallel middle body and an outflow section. The ratio to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com