Anti-rollover structure for fishing boat and its application method

An anti-rollover, fishing boat technology, applied in fishing boats, boat safety, ships, etc., can solve problems such as affecting the driving speed, energy consumption, and overturning of the bow and stern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

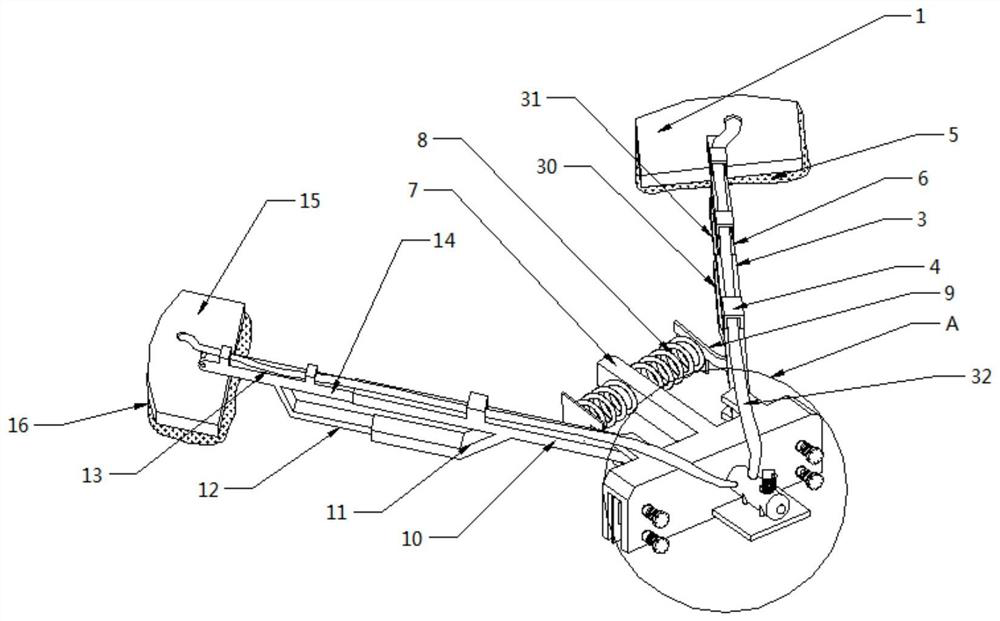

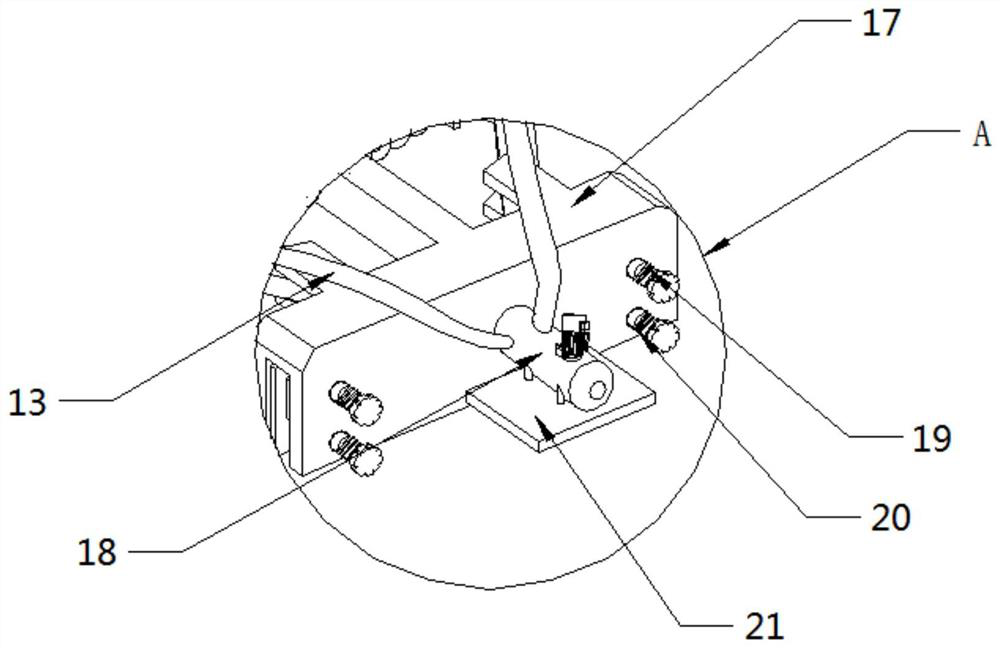

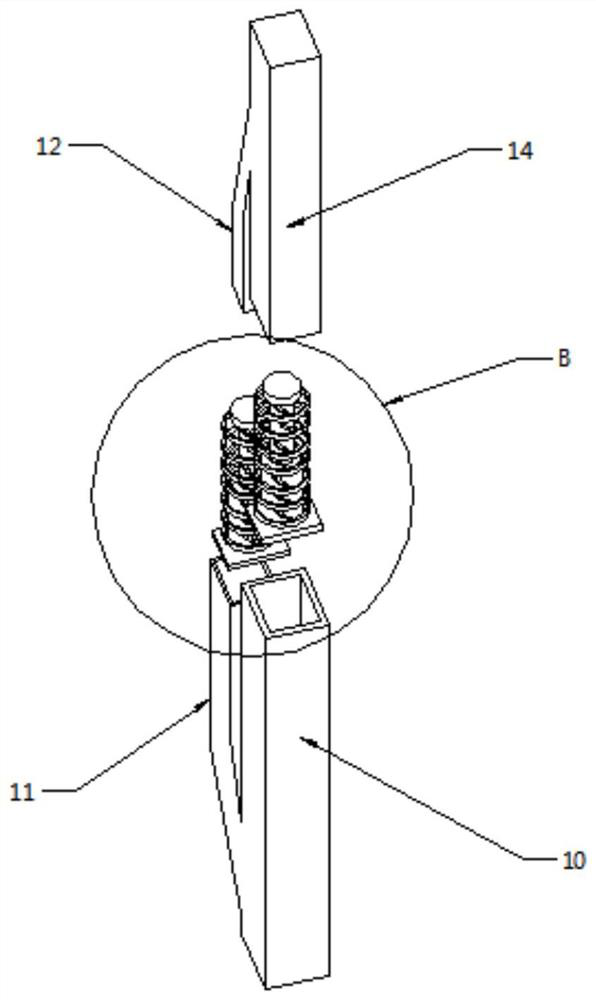

[0037]Such asFigure 1 - Figure 8As shown, the present embodiment is provided for the anti-side tuning structure of the fishing vessel, including the gantry clamping frame 17 and the second hinge barrel 10 and the second hinge barrel 10 and hinged in the top of the outer wall of the gantry clamping frame 17. The first hinge barrel 3 of the other side of the outer wall of the clamp holder 17, the inner sleeve of the second hinge barrel 10 is provided with a second telescopic support rod 14 that slides in the inner side of the second hinge barrel 10, and the second telescopic support rod 14 is away from One end of the gantry clamping frame 17 is hinged to a second floating plate 15, and the bottom of the second floating plate 15 is fastened to the second balloon 16, and the first reamer 3 is away from one end of the gantry clamp 17. A first telescopic support rod 6 can be slid in the first hinge bar 3, and the first telescopic support rod 6 is hinged from one end of the gantry clamp 17...

Embodiment 2

[0048]A method of use of anti-sided tuning structures for fishing boats, including the following steps:

[0049]The installation step: release the first fixing screw 19 and the second fixing screw 20, insert the inner side of the gantry clamping frame 17 into the side of the hull, by rotating the first fixed screw 19 and the second fixed screw 20 to pass The first fixing screw 19 pushes the sliding clamping plate 29 to move on the strip slide rod 26, and is in contact with the hull side contact, so that the fixing clamping plate 27 is in contact with the outer side of the hull, through the second limit The bit spring 28 is further fastened, and then tightened by the second fixing screw 20 and the inner side of the hull;

[0050]Automatic anti-side stepp: After touching the pressure through the pressure sensor 34 and the water surface contact, the pressure information is transmitted to the PLC controller, and the supply exhaust gas pump 18 is controlled by the PLC controller to supply the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com