Inland river amphibious type hoisting engineering ship and using method

A technology for engineering ships and inland rivers, applied to cranes, etc., can solve problems such as waste of energy consumption, inability to adapt to large water level difference wharves, waste of crane lifting efficiency, etc., and achieve the effect of saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

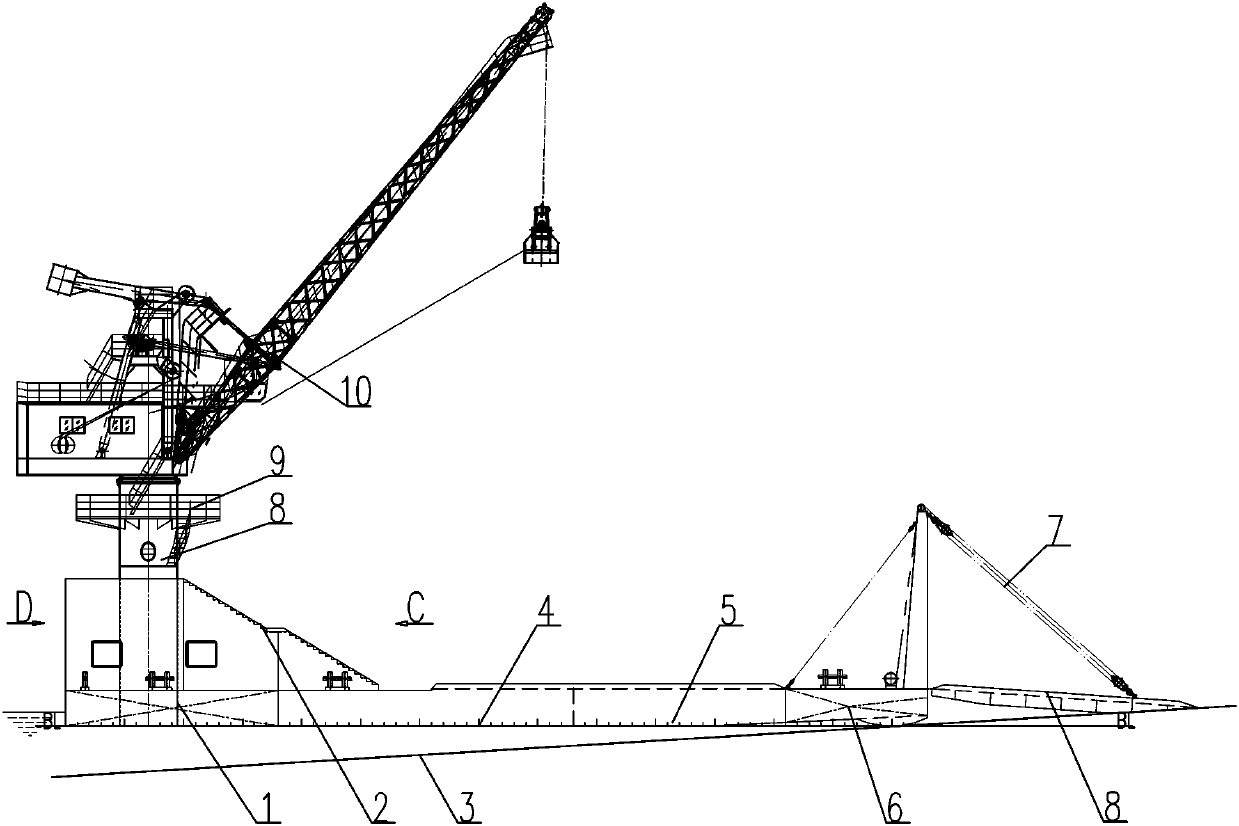

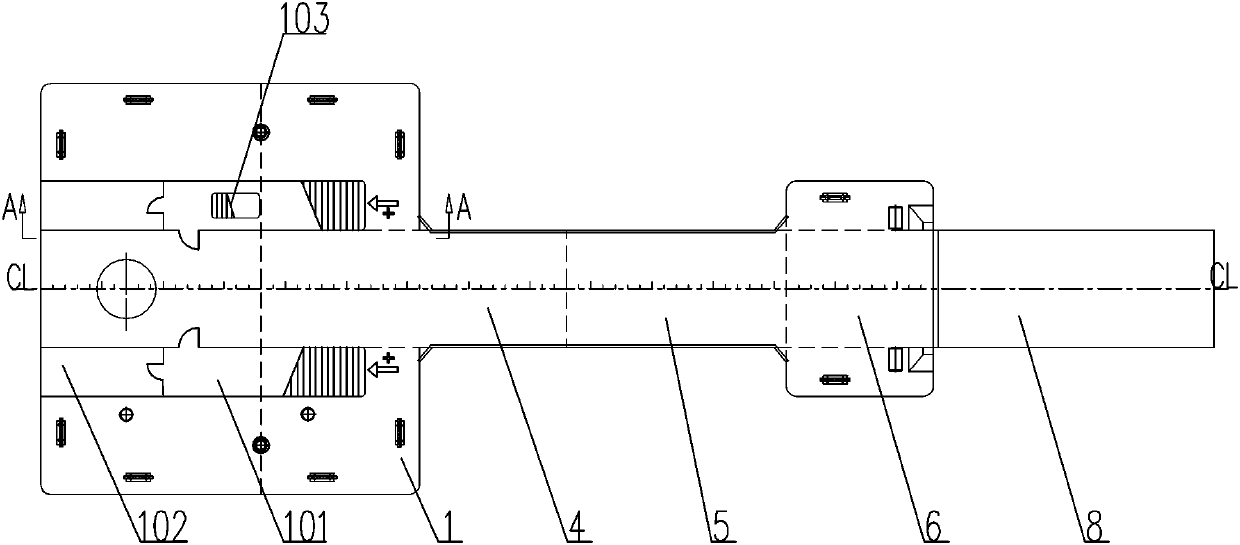

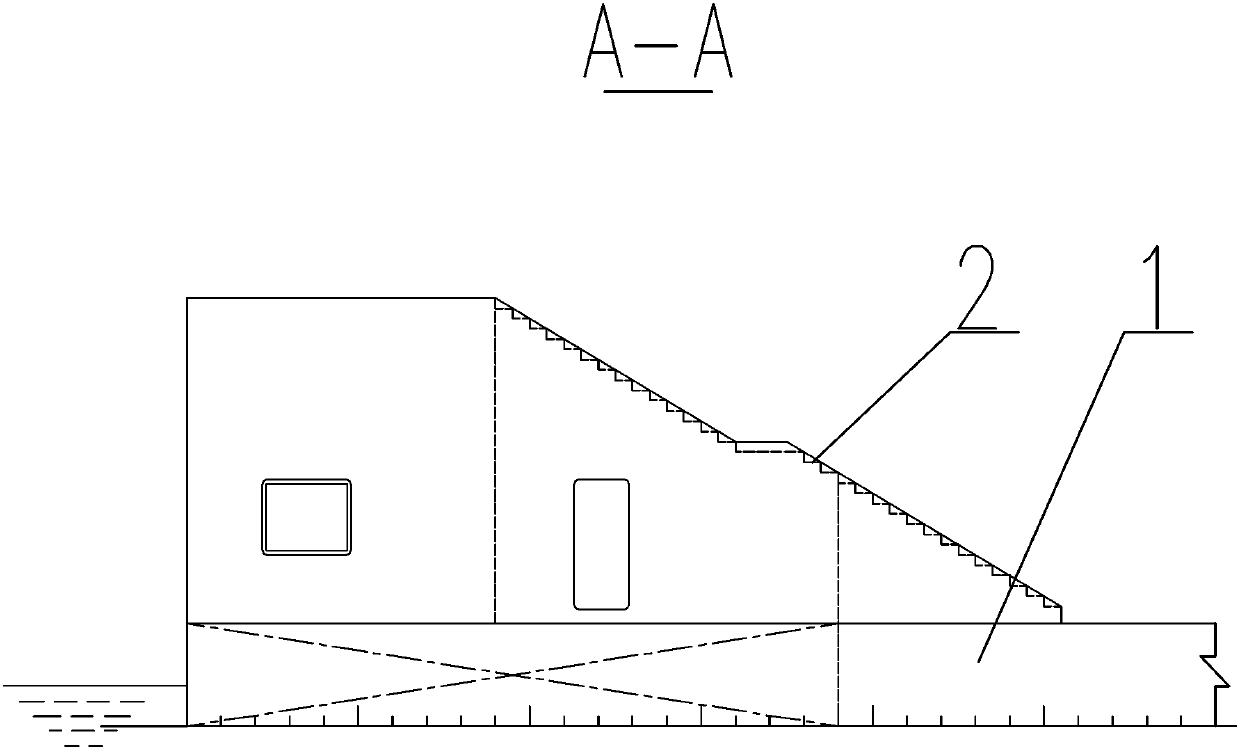

[0056] see Figure 1-22 , an inland river amphibious lifting engineering ship, which includes a main hull, and the main hull includes a tail ballast tank structure 1 floating in the inland river part, and the tail ballast tank structure 1 is sequentially provided with a first empty tank 4 and The second empty cabin 5, after which the second empty cabin 5 is provided with the head ballast tank structure 6 for anchoring and supporting with the inland river bank foundation; the top of the tail ballast tank structure 1 is fixedly installed with a crane foundation Seat 8, the top of the crane base 8 is equipped with a floating crane 10, the end of the head ballast tank structure 6 is hinged with a springboard structure 8 mounted on the shore, the springboard structure 8 and the head pressure A springboard lifting device 7 for driving its lifting is installed between the loading cabin structures 6 . The lifting engineering ship with the above-mentioned structure can directly realiz...

Embodiment 2

[0066] The method for loading and unloading the inland river amphibious lifting engineering ship includes the following steps:

[0067] Step1: When unloading, anchor the head ballast tank structure 6 of the lifting engineering ship to the shore foundation, and make the entire lifting engineering ship berth with the shore foundation in a T-shape, and pass the tail ballast tank structure 1 through The cable is connected with the anchor pile on the ground to realize the anchorage of the lifting engineering ship;

[0068] Step2: Start the springboard lifting device 7, use the springboard structure 8 below the springboard lifting device 7 to support and dock it with the shore foundation, so that operators and transport vehicles can board the lifting engineering ship for operations;

[0069] Step3: drive the ship to be unloaded to the position of the stern ballast tank structure 1, and make the length direction of the hull contact with the side wall of the stern ballast tank structu...

Embodiment 3

[0074] The present invention is described further with a practical engineering example here:

[0075] Main dimensions of the ship in this embodiment:

[0076] Total length: 48m including springboard Design draft: 1.0m

[0077] Waterline length: 36.5m Navigation area: BJ2

[0078] Ship length: 36.5m Rib spacing: 0.5m

[0079] Molded width: 4.8m beam arch: 0.15m

[0080] The total width of the pontoon is 16.8m

[0081] Molded depth: 1.5m crane capacity / maximum range of work; 20 / 30m

[0082] refer to Figure 1-22 , an inland river amphibious lifting engineering ship, including a hull, below the main deck of the hull: a first ballast tank 106, a second ballast tank 107, a pump room 105, a first empty tank 4, The second empty tank 5 and the head ballast tank structure 6;

[0083] The head ballast tank structure 6 is provided with a boom base from the main deck to the bottom of the ship; the bow is hinged with a springboard structure 8, and the springboard structure 8 is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com