Centrifugal pump for deep well

A centrifugal pump and deep well technology, applied in the field of fluid machinery, can solve the problems of increasing the length of the well pump and production cost, reducing the axial size of the well pump, increasing the single-stage lift, etc., so as to improve the efficiency of the pump, reduce the production cost, improve the The effect of single-stage lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

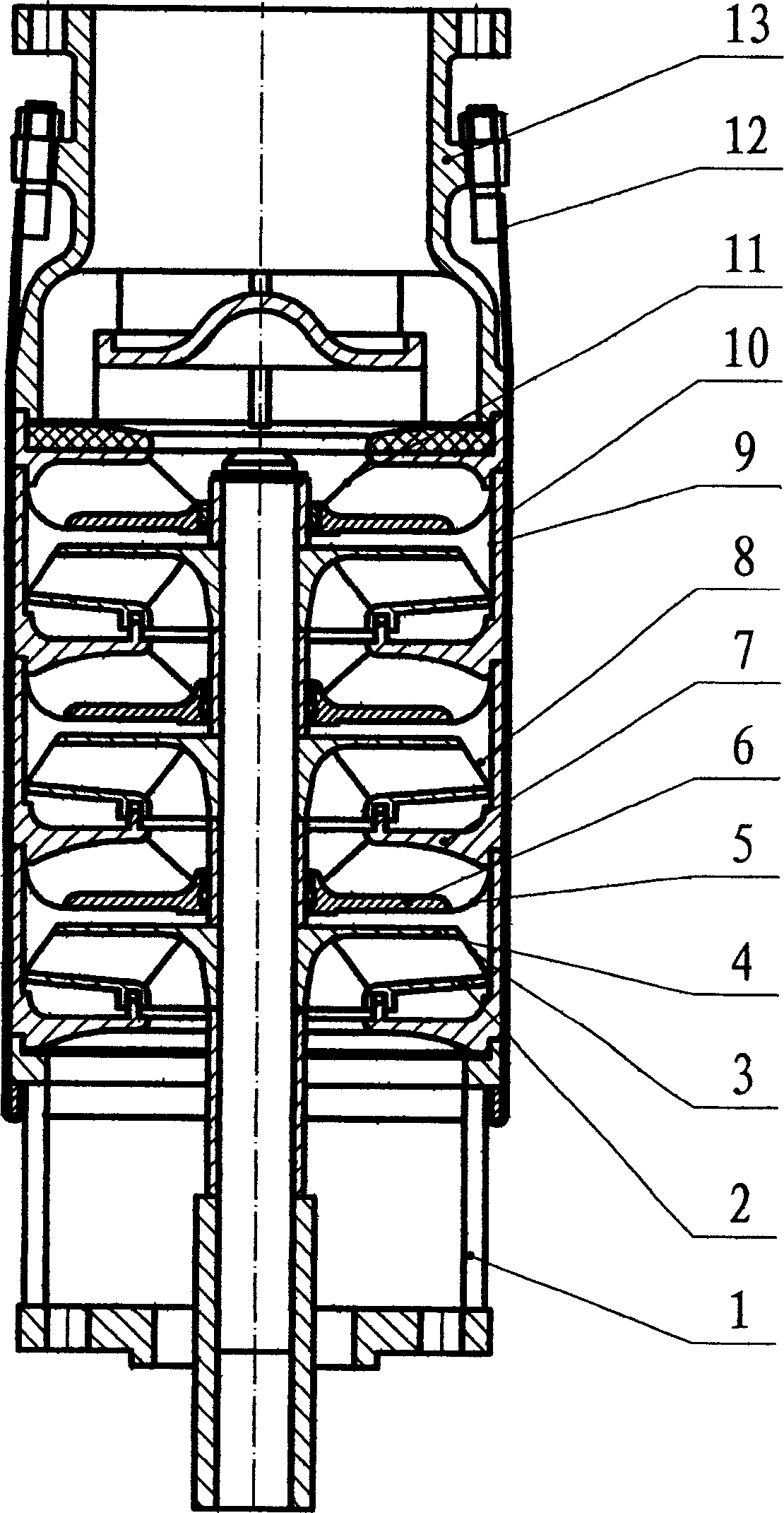

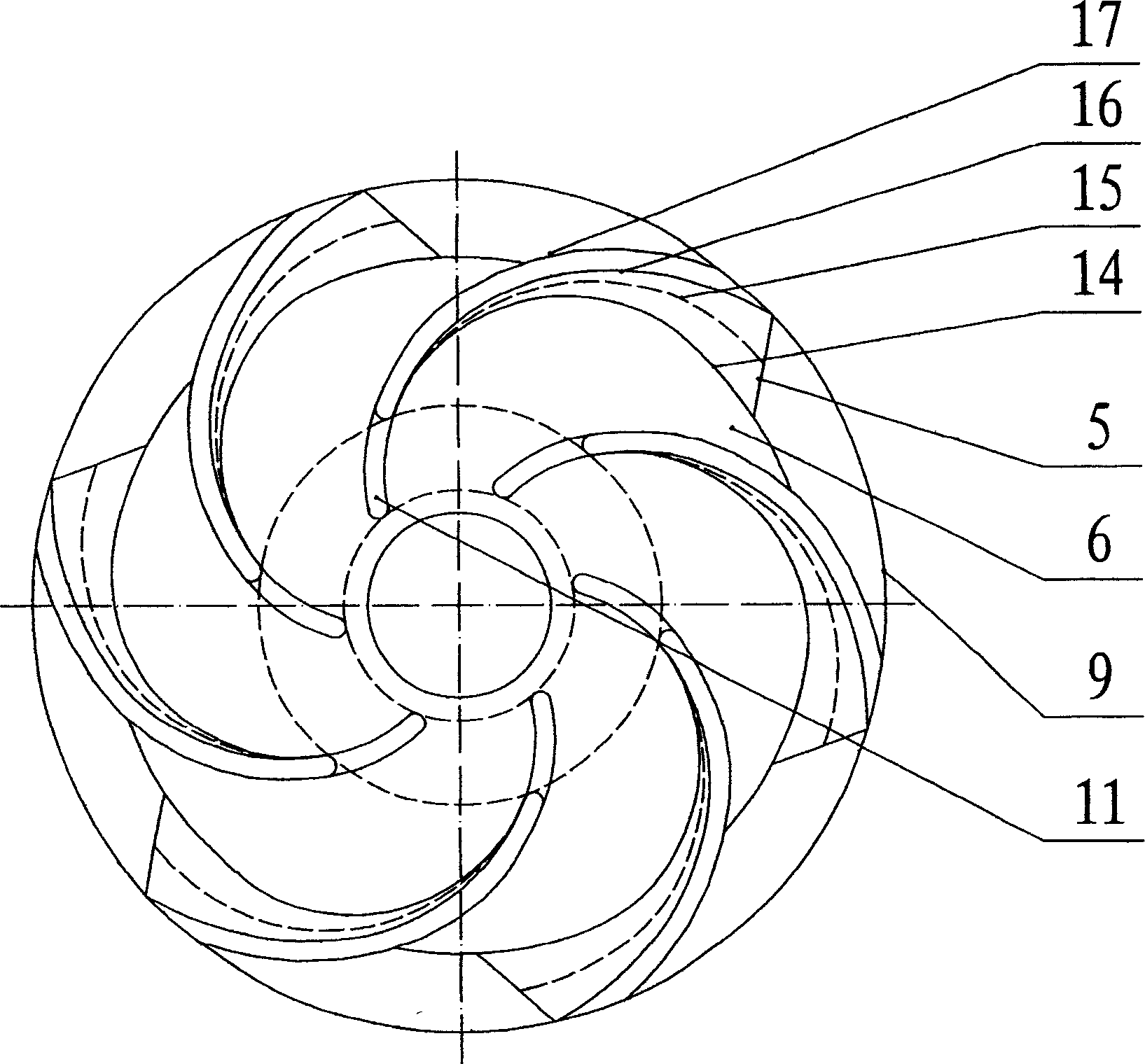

[0015] figure 1 The model of the deep well centrifugal pump in the shown embodiment is 250QJ125. According to the national standard GB / T2816-2002 "Submersible Pump for Wells", the outer diameter of the diversion shell (10) must be designed to be about φ220, and the diversion is designed through strength calculation The shell wall thickness is 6mm, the outer diameter of the guide shell (10) minus twice the thickness of the guide shell, the maximum inner diameter (9) of the guide shell is about φ208, and the inlet area required by the guide vane can be determined according to the rated flow. It is calculated that the outer diameter of the lower cover plate (6) of the guide vane of the deflector shell is about φ170. The impeller adopts a closed impeller with front and rear cover plates. The outer diameter of the front cover plate (2) of the impeller is approximately equal to the maximum diameter of the deflector shell. The inner diameter (9) is designed to be about φ207. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com