Spot welding method, spot welding machine and spot welding robot

A technology of spot welding equipment and robots, which is applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of resistance change, inability to accurately determine, and change of conductive area, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

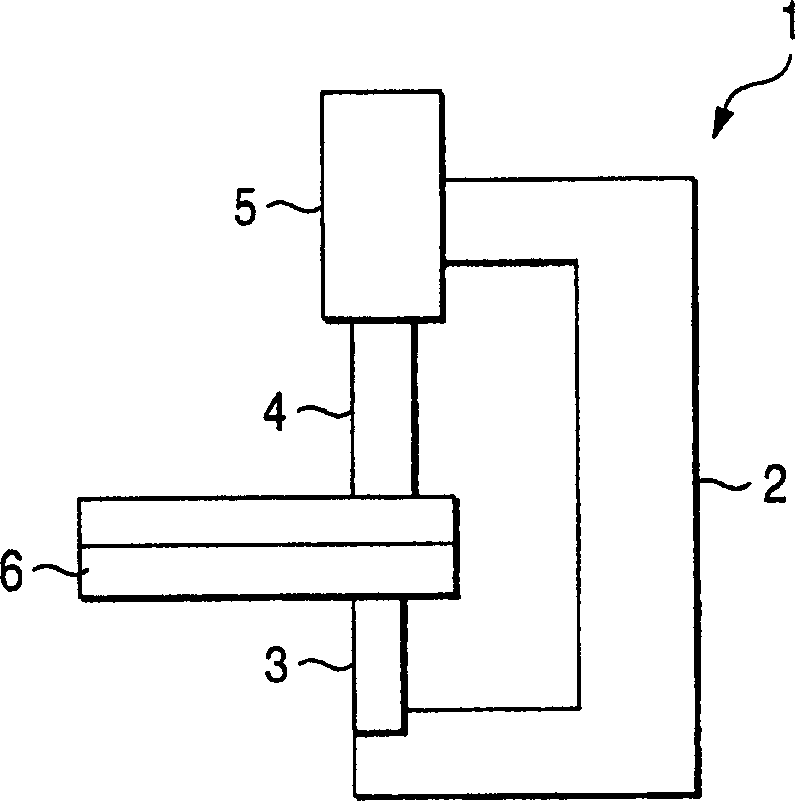

[0021] figure 1 is a conceptual diagram of a spot welding gun and shows an embodiment of the present invention. In this drawing, reference numeral 1 denotes a spot welding gun. The spot welding gun 1 is integrally equipped with an unshown transformer, and is mounted on the front end of an unshown robot to move the spot welding gun 1 to a position programmed in a control device of the aforementioned robot, thereby performing spot welding.

[0022] Reference numeral 2 denotes a frame of the spot welding gun 1, and a fixed electrode 3 is mounted on the lower part of the frame, and a movable electrode 4 is mounted on the upper part. The movable electrode 4 is driven by a servo motor 5 to move it up and down to clamp and press a workpiece 6 between itself and the fixed electrode 3 . By the above-mentioned control device of the above-mentioned robot, the servo motor 5 is controlled as an additional axis of the robot, so that the position, speed, and thrust (or pressure) of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com