Plasma display screen fault checking method

A technology of a plasma display screen and an inspection method, which is applied in the direction of measurement/testing in the manufacturing process, and can solve problems such as inability to perform inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method described in the present invention will be further described below in conjunction with the accompanying drawings and the embodiments provided by the inventor.

[0017] Taking the inspection of the bus electrode of the substrate on the 60-inch plasma display as an example to further illustrate this inspection method.

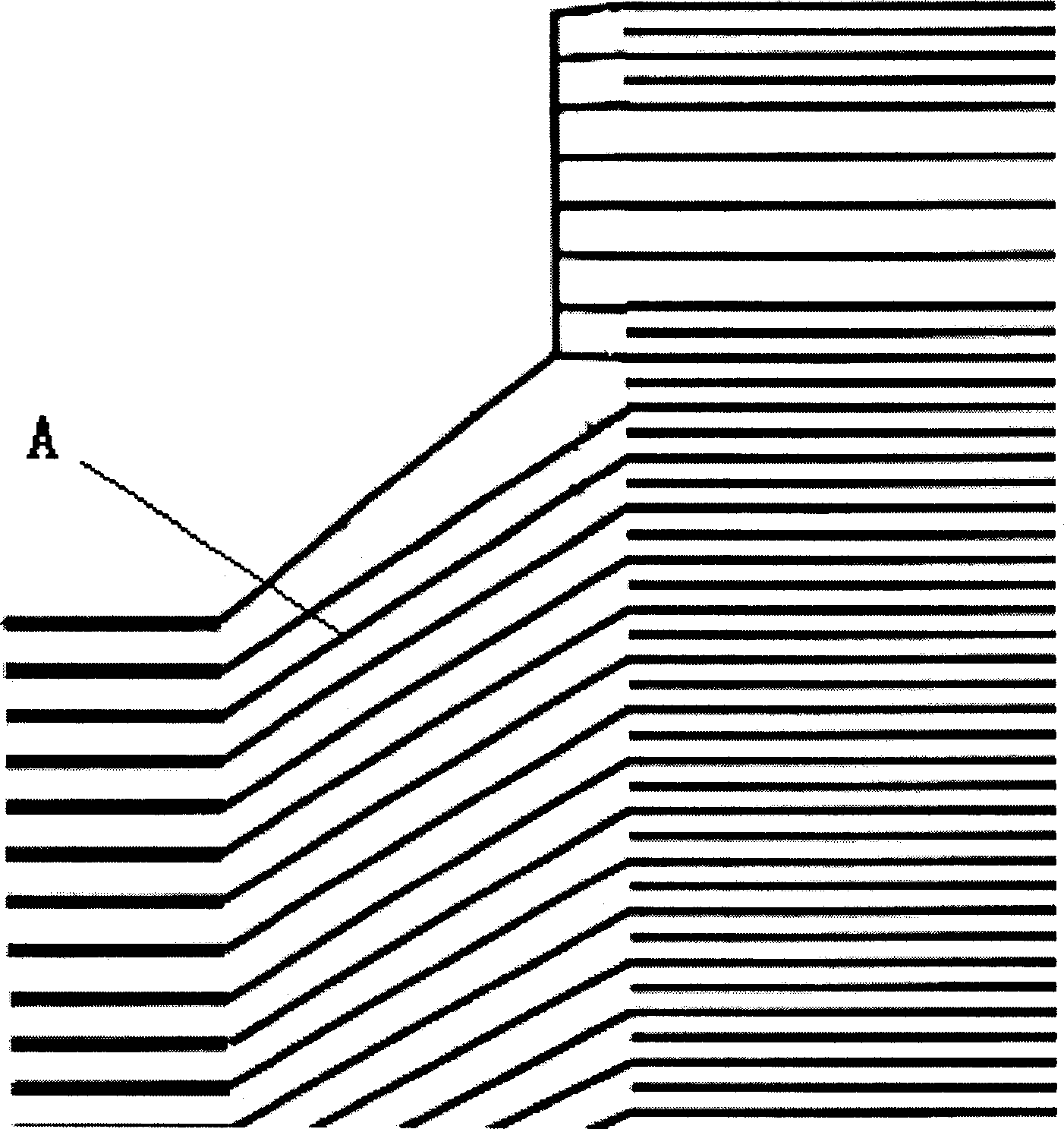

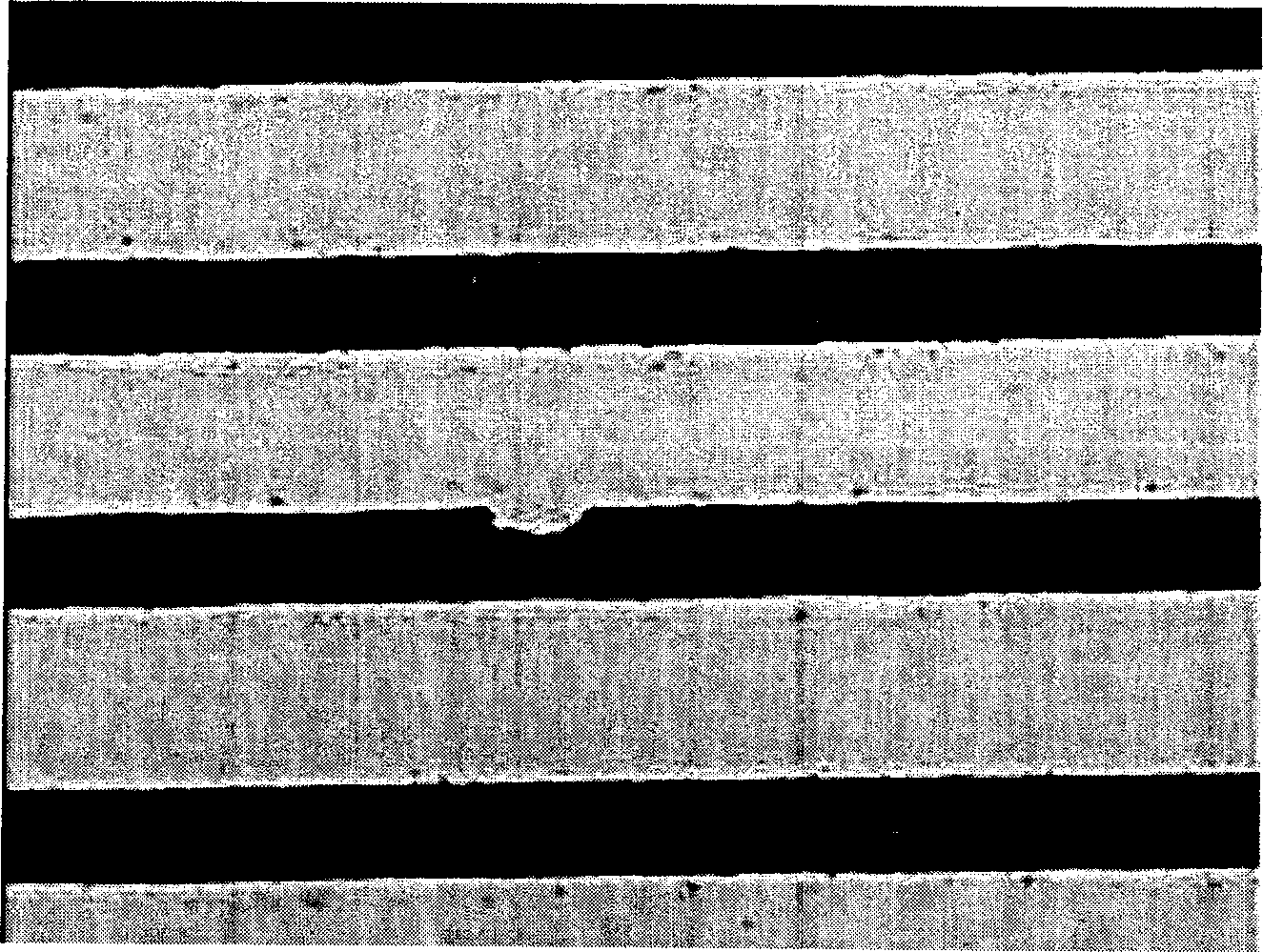

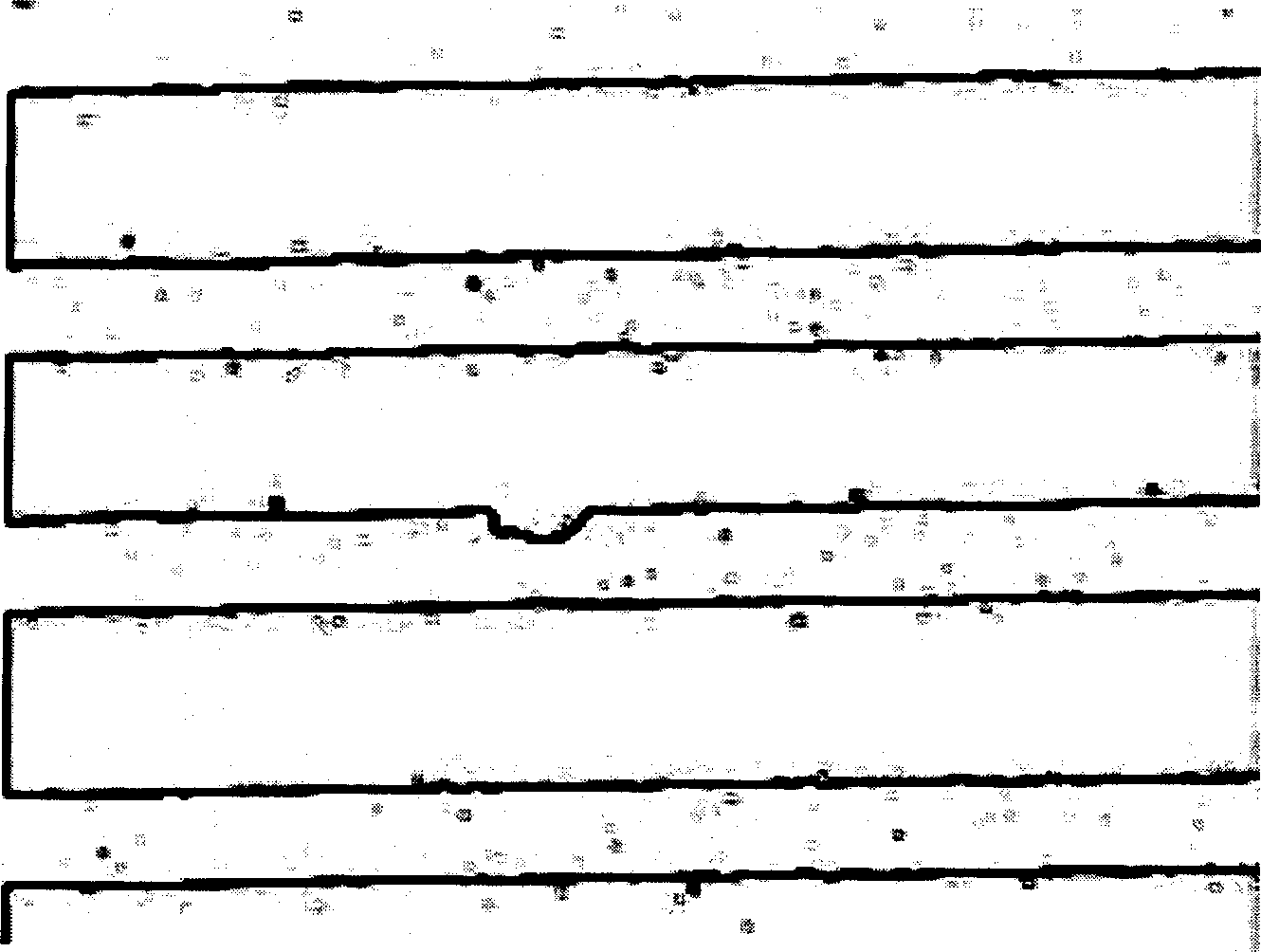

[0018] First use CCD camera to shoot figure 1 A surface image of a portion of the bus electrodes of the plasma display shown. The principle of controlling the brightness of the lighting source during shooting is that the bus electrode lines can be clearly seen on the captured image, and the gray value of the line part and the glass substrate without the line is obviously different, which is convenient for thresholding processing in the later stage. The entire surface of the substrate is evenly illuminated. In this example, segmented brightness-controllable high-frequency fluorescent tubes are used as the lighting source.

[0019] After the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com