Dumper with two-sided turnable chassis

A technology for dump trucks and bottom plates, which is applied in the direction of inclined load-carrying vehicles, etc., which can solve problems such as unbalanced loads on the vehicle body, lower working efficiency of dump trucks, and prone to rollover accidents, etc., and achieve the effect of improving work efficiency and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

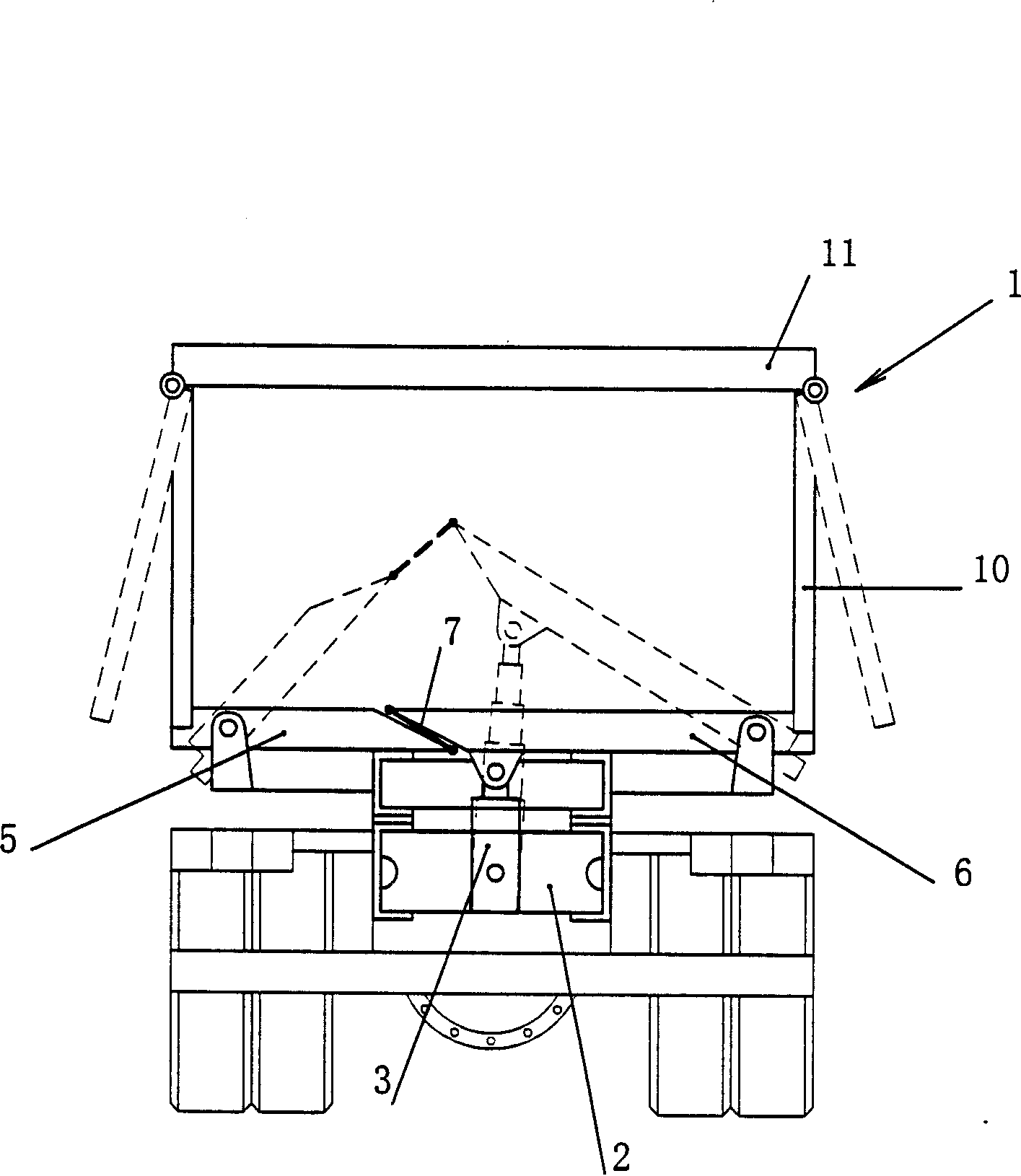

[0012] As can be seen from Fig. 1, the bottom plate double-sided flip dump truck of the present invention includes a car body 1, a car body frame 11, a side plate 10 and a chassis 2, and the left and right sides of the body 1 or the chassis 2 are respectively It is hingedly connected to the outer ends of the left and right bottom plates 5 and 6, the inner end of the left bottom plate 5 and the inner end of the right bottom plate 6 overlap each other, and a connecting plate 7 is provided between the overlapping parts of the left bottom plate 5 and the right bottom plate 6. The left and right sides of the plate 7 are hingedly connected to the inner edge of the left base plate 5 and the right base plate 6 respectively, and the lower surface of the left base plate 5 or the right base plate 6 is connected to the driving device, and the driving device is installed on the vehicle chassis 2. The driving device includes at least one jacking cylinder 3 installed on the chassis 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com