Housed bush roller assembly

A component and bushing technology, applied in the field of rollers of automobile sliding doors, can solve the problems of loss of rolling low friction contact, lack of corrosion resistance and low-cost design, damage to doors and/or door frames, etc., to achieve low production costs, The effect of simple structure, high strength and load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described with reference to a preferred embodiment, which relates to a preferred use for a sliding door of a motor vehicle. However, other carrying applications also fall within the protection scope of the present invention and its application is not limited to any specific application form. For example, the invention may be used in lifting equipment, handling equipment or other load bearing applications that typically use ball bearing rollers and would benefit from the advantages of the invention.

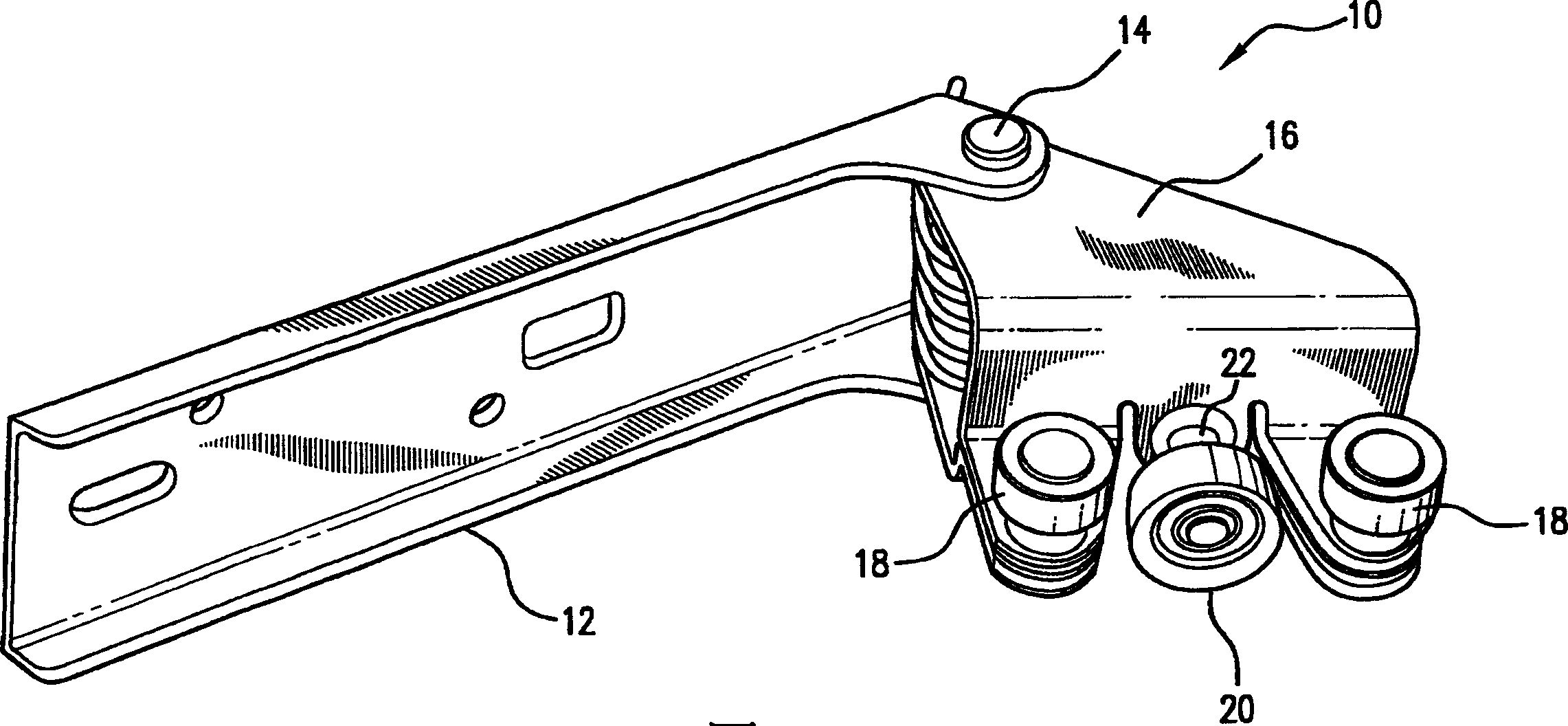

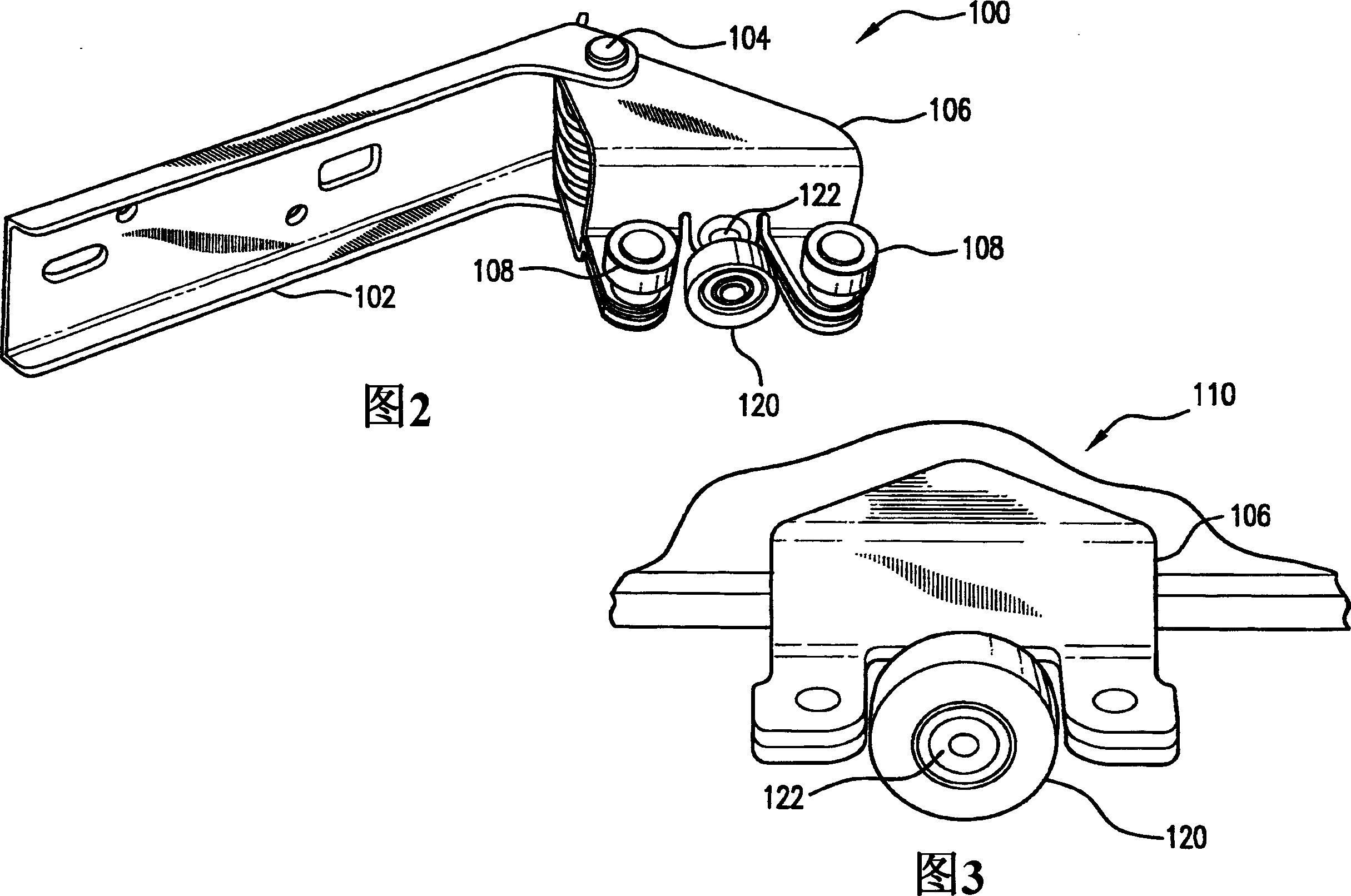

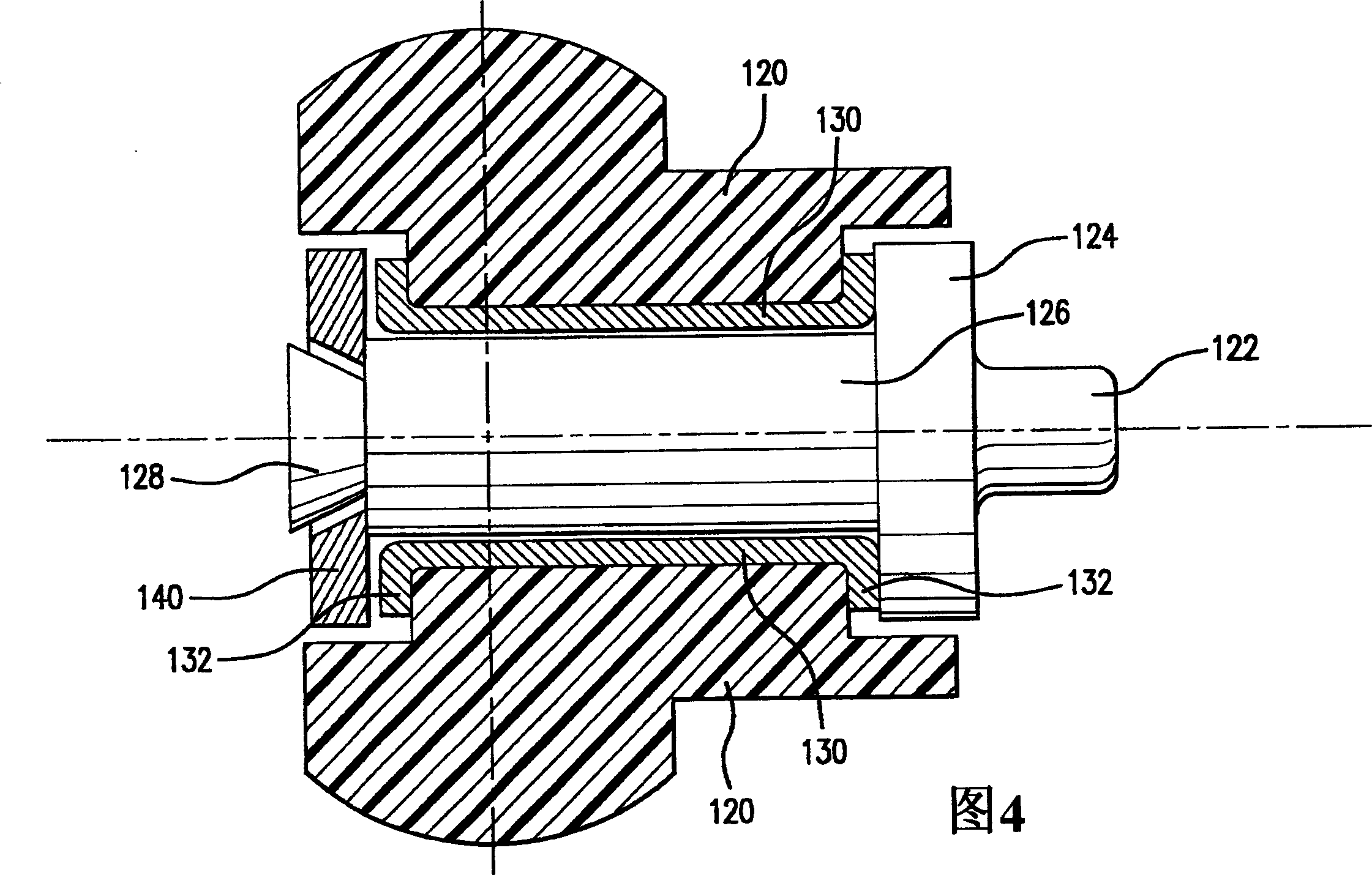

[0027] In a first aspect of the present invention, there is provided a roller assembly comprising a sliding bracket adapted to be fixed to a moving object and a backup roller assembly fixed to the bracket. Figure 4 depicts a preferred embodiment of the backup roll assembly. The backup roller assembly includes a roller 120 , a bushing 130 and a pin 122 .

[0028] In one embodiment of the present invention, the roller 120 is constructed of a rigid plas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap