Refrigerator

A technology of refrigerators and coolers, applied in the field of refrigerators, which can solve problems such as longer cooling operation time, lower cooling capacity, and flow, and achieve the effects of improving cooling efficiency, eliminating cooling loss, and eliminating flow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

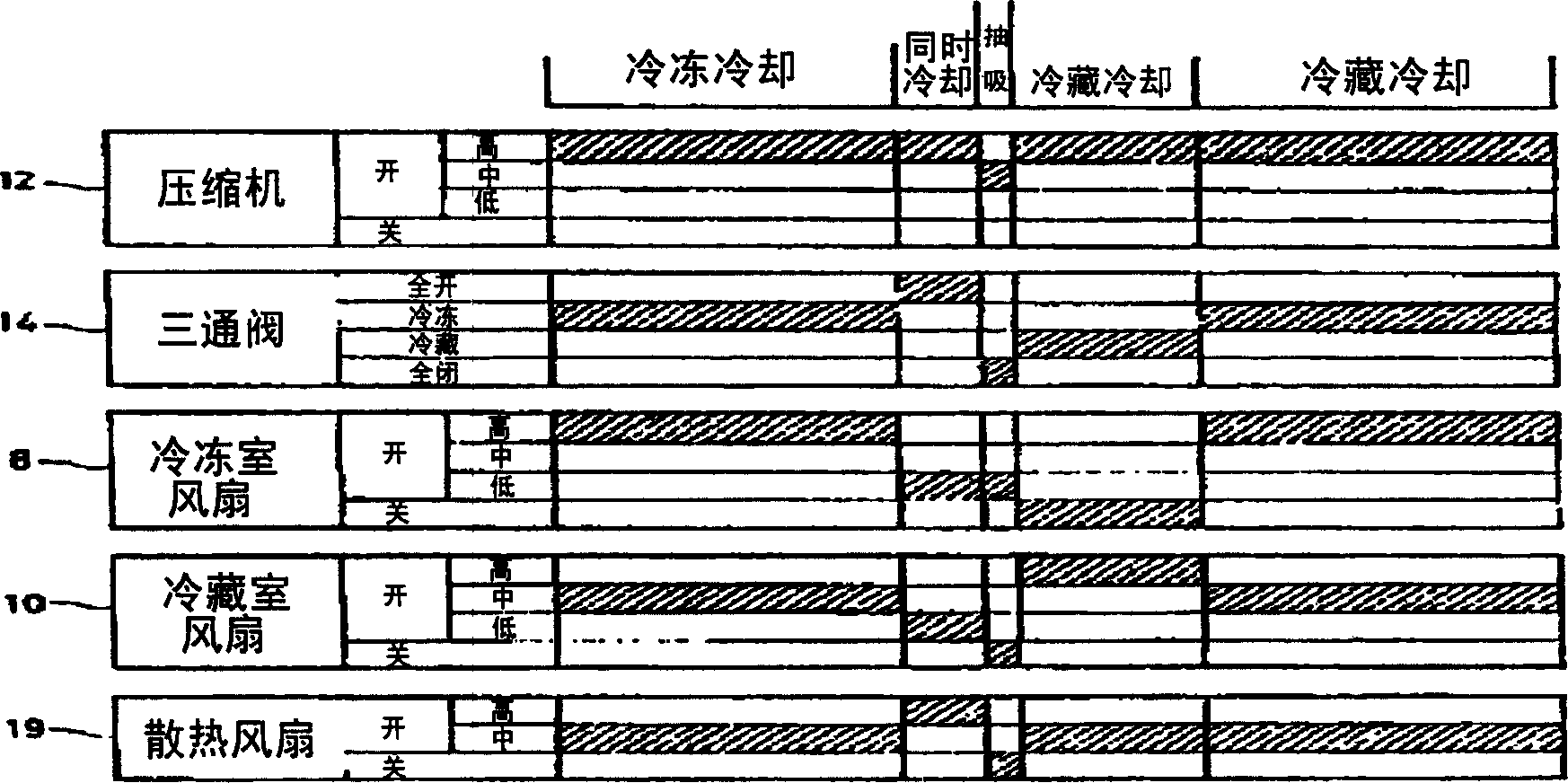

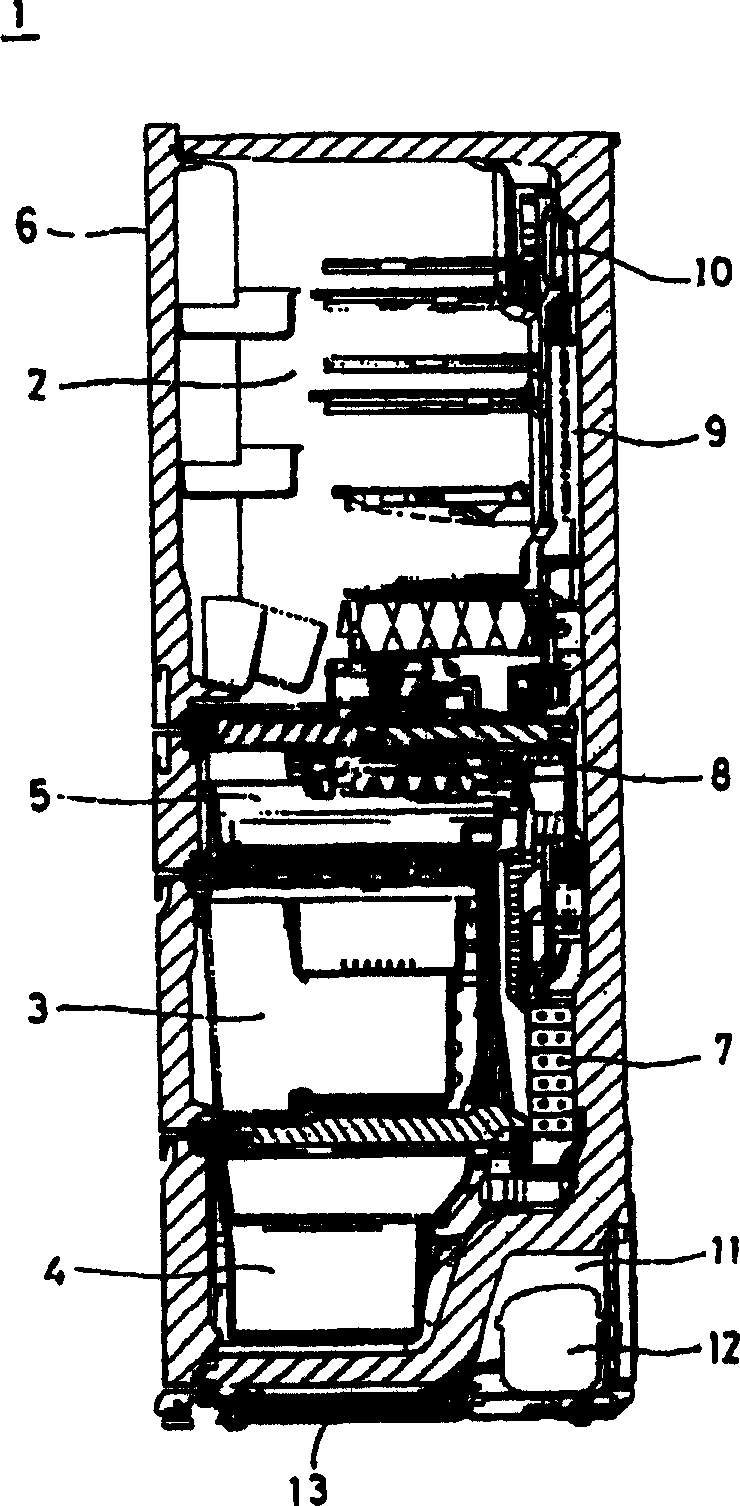

[0021] An embodiment of the present invention will be described below with reference to the accompanying drawings. figure 2 It is a vertical cross-sectional view of the refrigerator. The interior of the refrigerator main body 1 formed by the heat-insulating box is used as a storage space, and the refrigerator compartment 2 is independently arranged on the uppermost part, the vegetable compartment 3 is arranged below the refrigerator compartment 2, and the freezer compartment is arranged on the lowermost part. 4. Between the refrigerator compartment 2 and the vegetable compartment 3, an automatic ice-making compartment 5 and an unillustrated multi-temperature switching compartment are arranged side by side through a heat-insulating partition wall. The front openings of each storage compartment are respectively provided with dedicated doors. 6. Seal it freely with opening and closing.

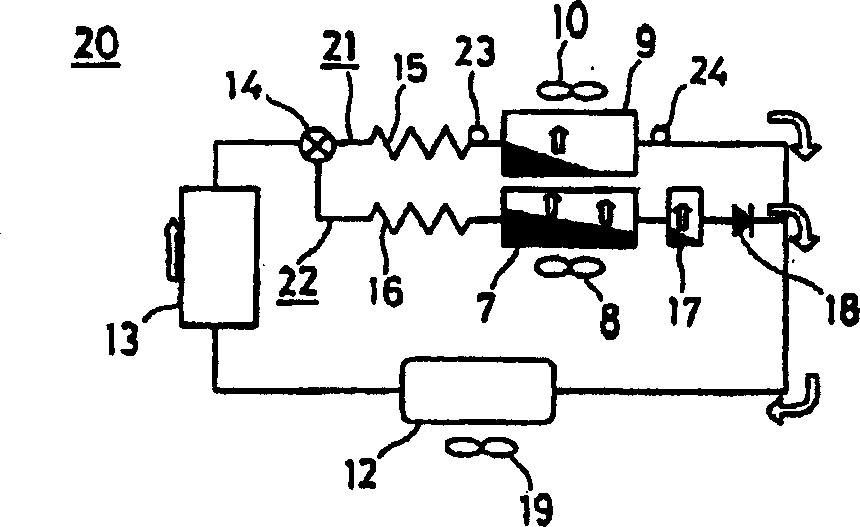

[0022] A cooler 7 for refrigerated storage spaces such as a freezer and an ice-making room, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com