Low-noise valve element device based on bionic structure vein fractal

A low-noise, leaf-vein technology, applied in the direction of valve device, valve device for absorbing fluid energy, sliding valve, etc., can solve the problems of high noise, vibration, and potential safety hazards, and achieve attenuation of medium and low frequency fluid pulsation and noise, which is not easy The effect of flow separation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

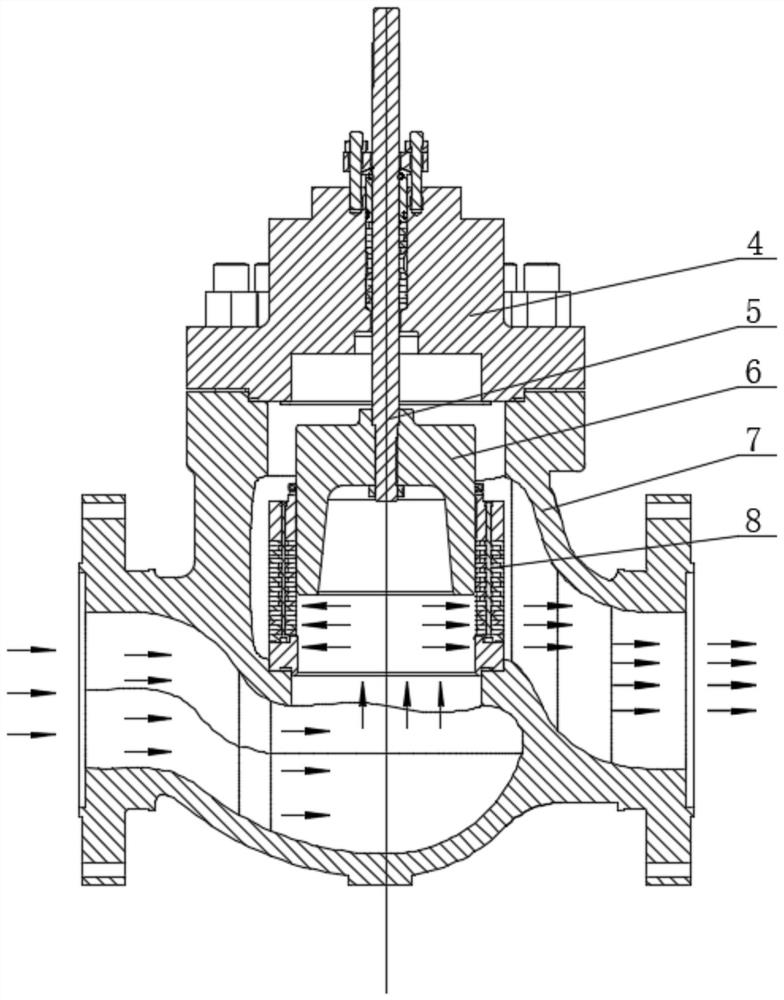

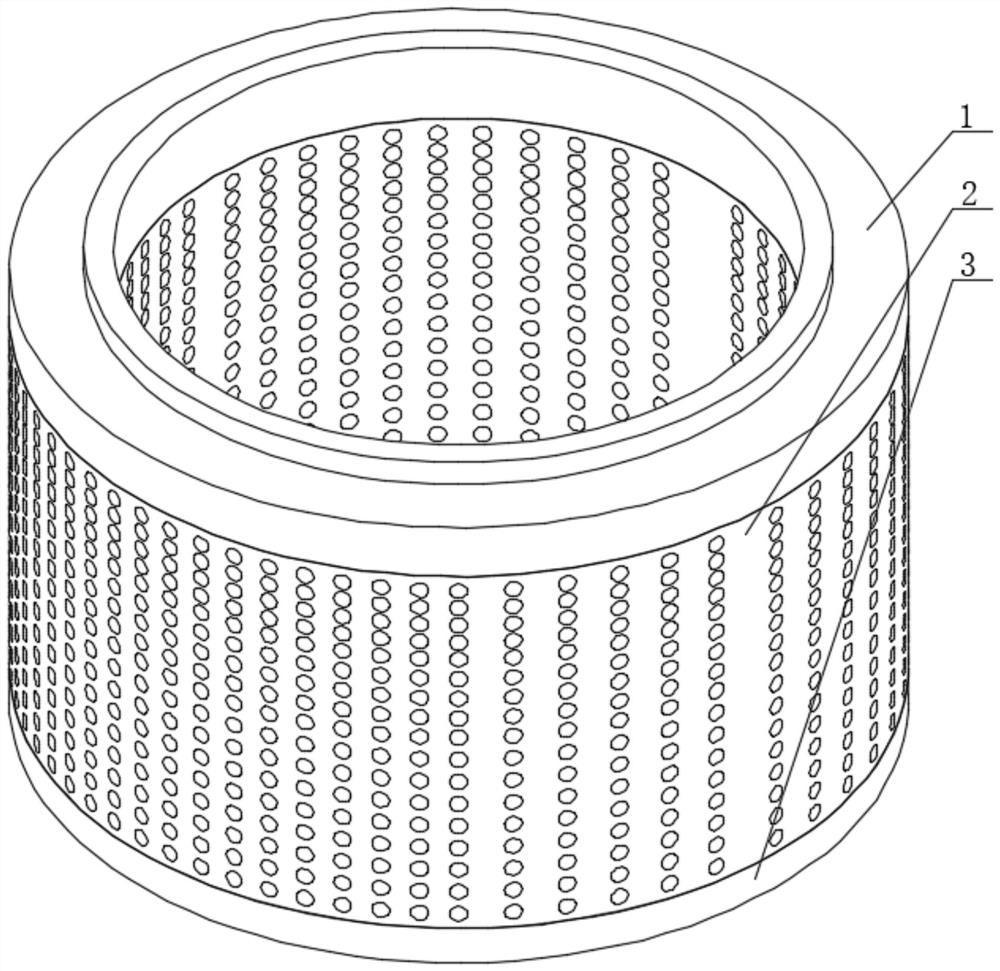

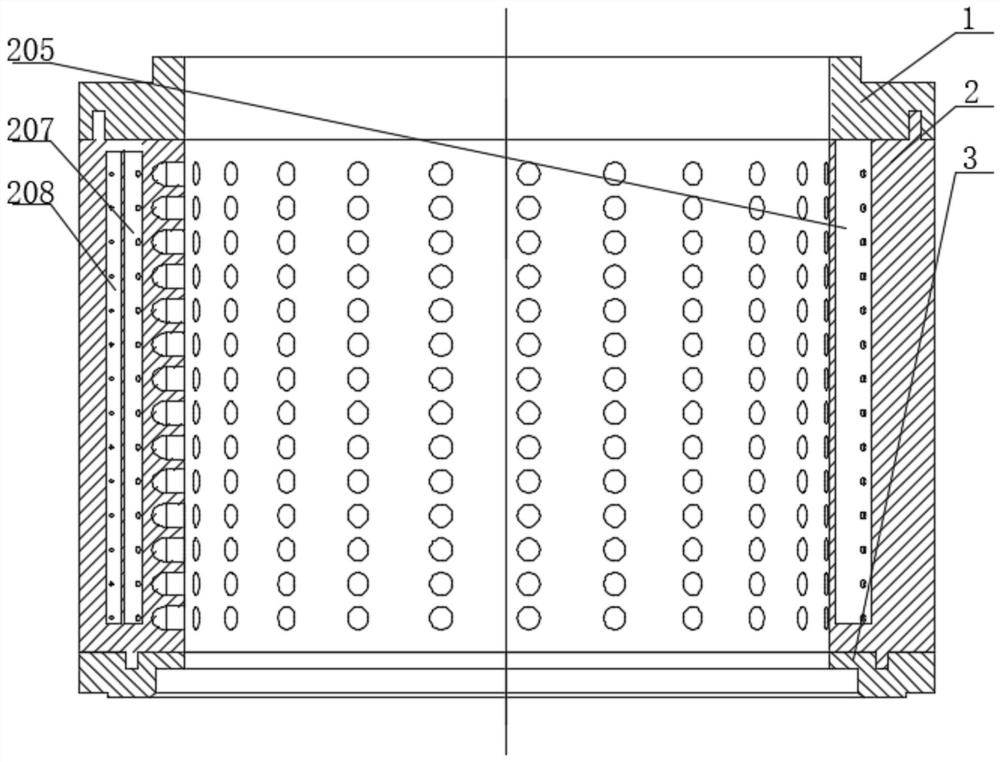

[0036] Such as Figure 1-Figure 7 As shown, the low-noise spool device based on the bionic structure leaf vein fractal of this embodiment includes a spool sleeve 8, and the structure of the spool sleeve 8 is as follows: it includes a sleeve body 2, and the sleeve body 2 is a hollow cylinder structure , the top surface and the bottom surface of the sleeve body 2 are provided with an annular protruding structure, the top surface of the sleeve body 2 cooperates with the sleeve upper cover 1, and the bottom surface of the sleeve upper cover 1 is equipped with the sleeve lower cover 3; The plane of the sleeve body 2 is distributed with a plurality of fluid passages with fractal structure of veins in the circumferential direction. The structure of a single fluid passage is as follows: from the inner wall surface of the sleeve body 2 to the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com