RF coaxial connector

A radio frequency coaxial and connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of high production cost, low production efficiency, and consumption of metal materials, and achieve high production efficiency and processing The effect of high efficiency and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

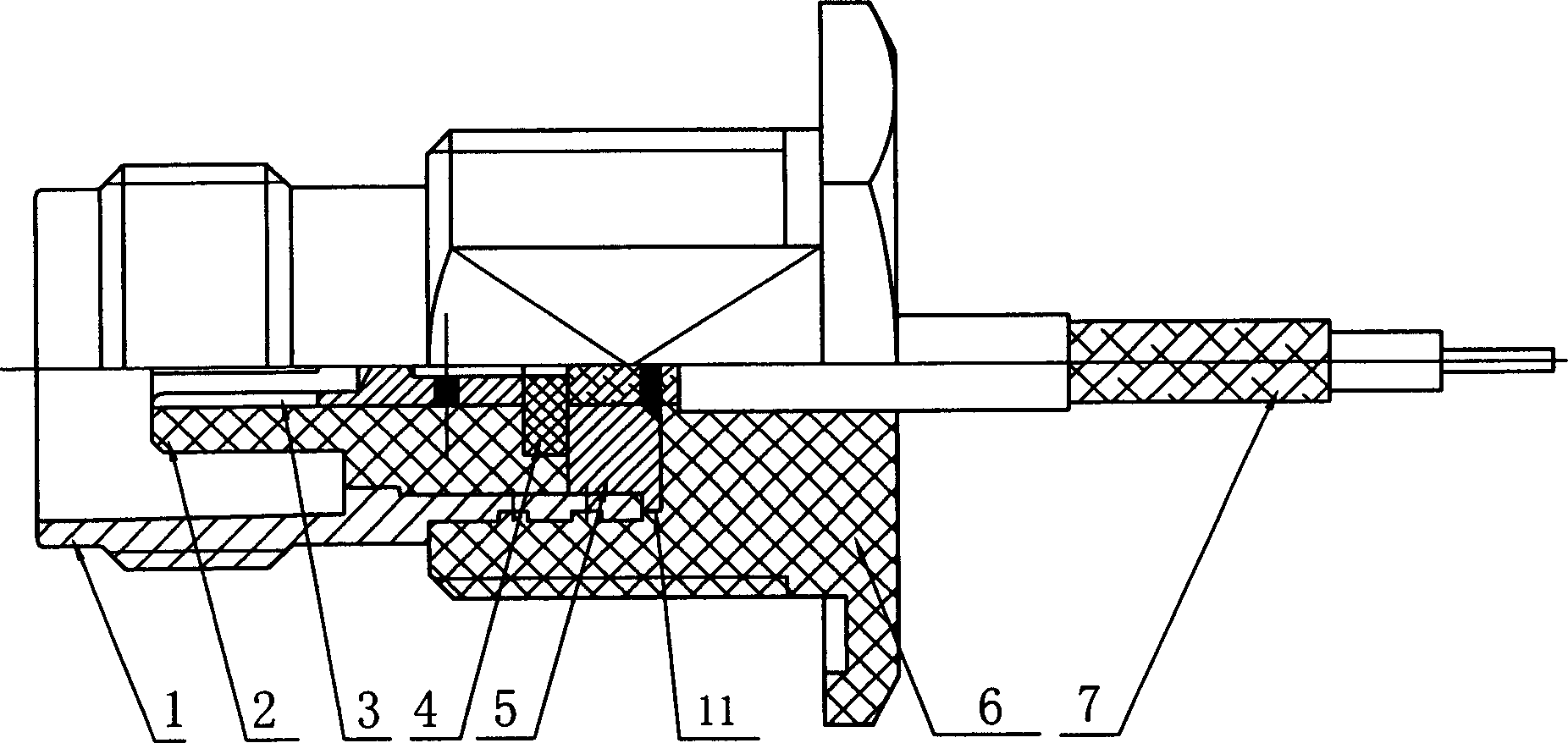

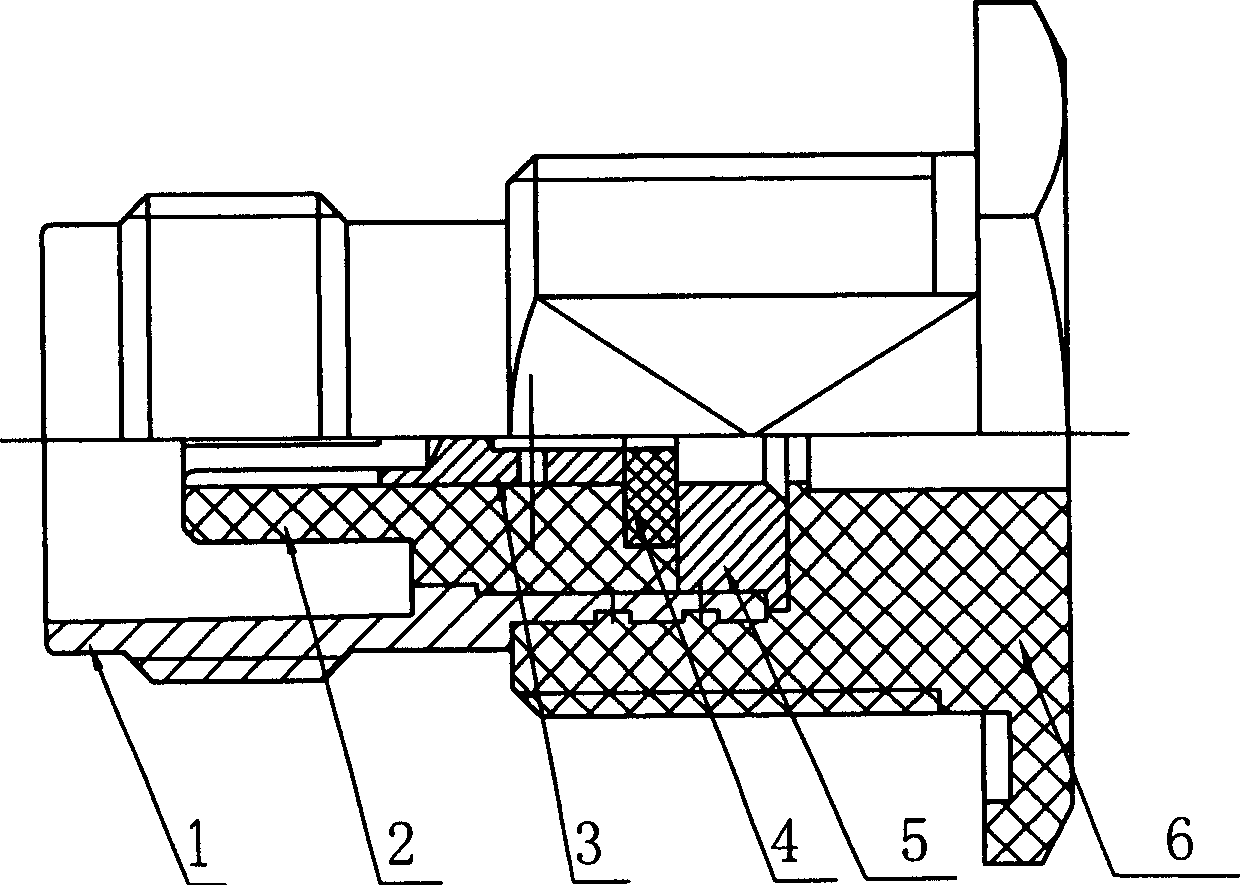

[0025] Embodiment 1: see attached figure 1 , 2 , 3 and 6.

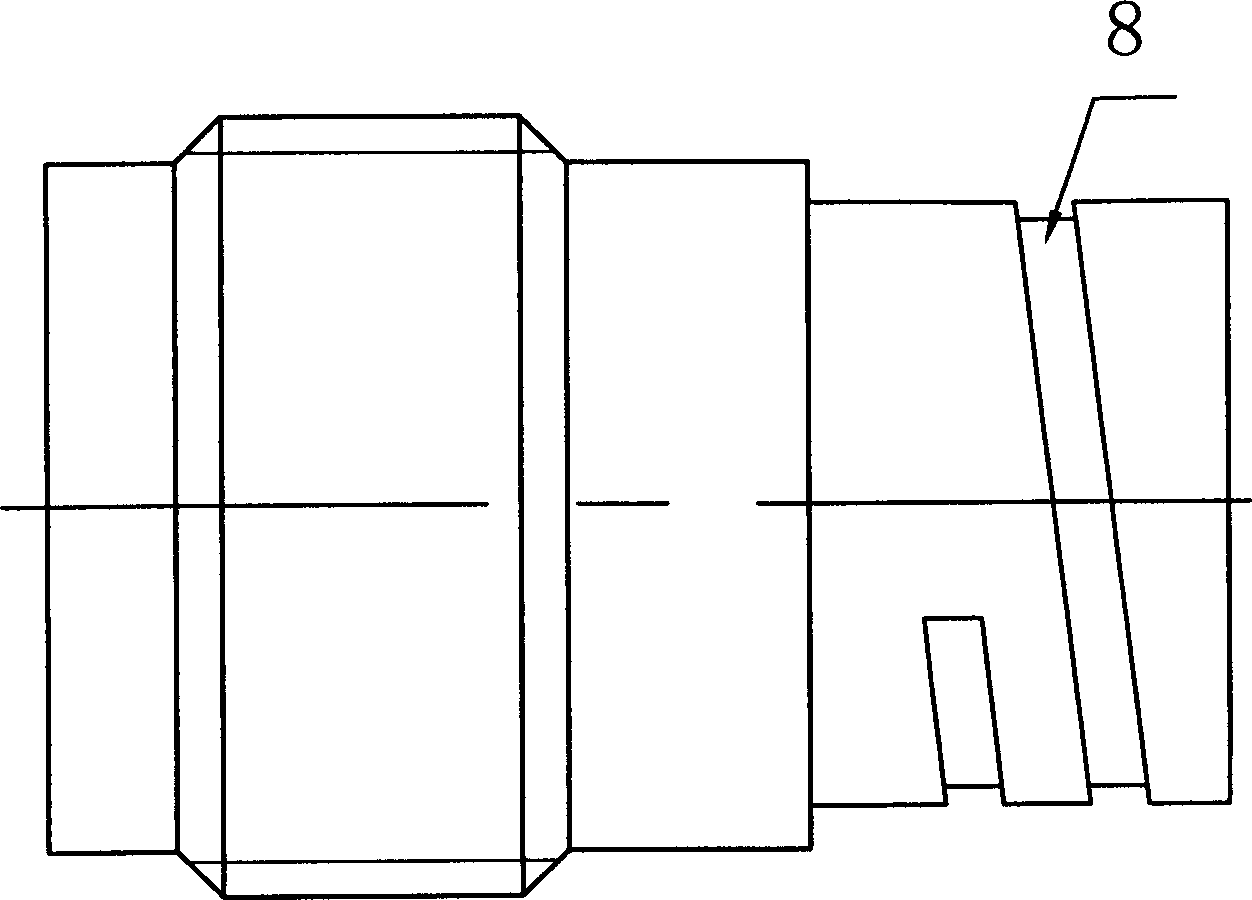

[0026] A radio frequency coaxial connector is composed of a shell, an insulator 2 arranged in the shell, an inner conductor 3 set in the insulator, a gasket 5 and an insulating spacer 4, and the shell is composed of a metal shell 1 fixedly connected by injection molding and The plastic shell 6 is formed; the metal shell 1 has a discontinuous spiral groove 8 .

[0027] When assembling, install the gasket 5, the insulating gasket 4, and the inner conductor 3 on the stripped radio frequency coaxial cable 7 in sequence (the gasket 5 can be installed first or later according to the specific situation); the inner conductor 3 and the coaxial cable The core wire of 7 is welded; the gasket 5 is welded with the shielding layer of the coaxial cable 7; the insulator 2 is mounted on the inner conductor 3 and pressed into the metal shell 1 as a whole; the plastic shell 6 is molded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com