Printing ink assembly for ink-jet printing

An inkjet ink and inkjet printing technology, which is applied in the inkjet field using the ink combination, can solve the problems of poor dyeing ability, failure to obtain bright red, difficult dispersion, etc., and achieve the effect of expanding the range of color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

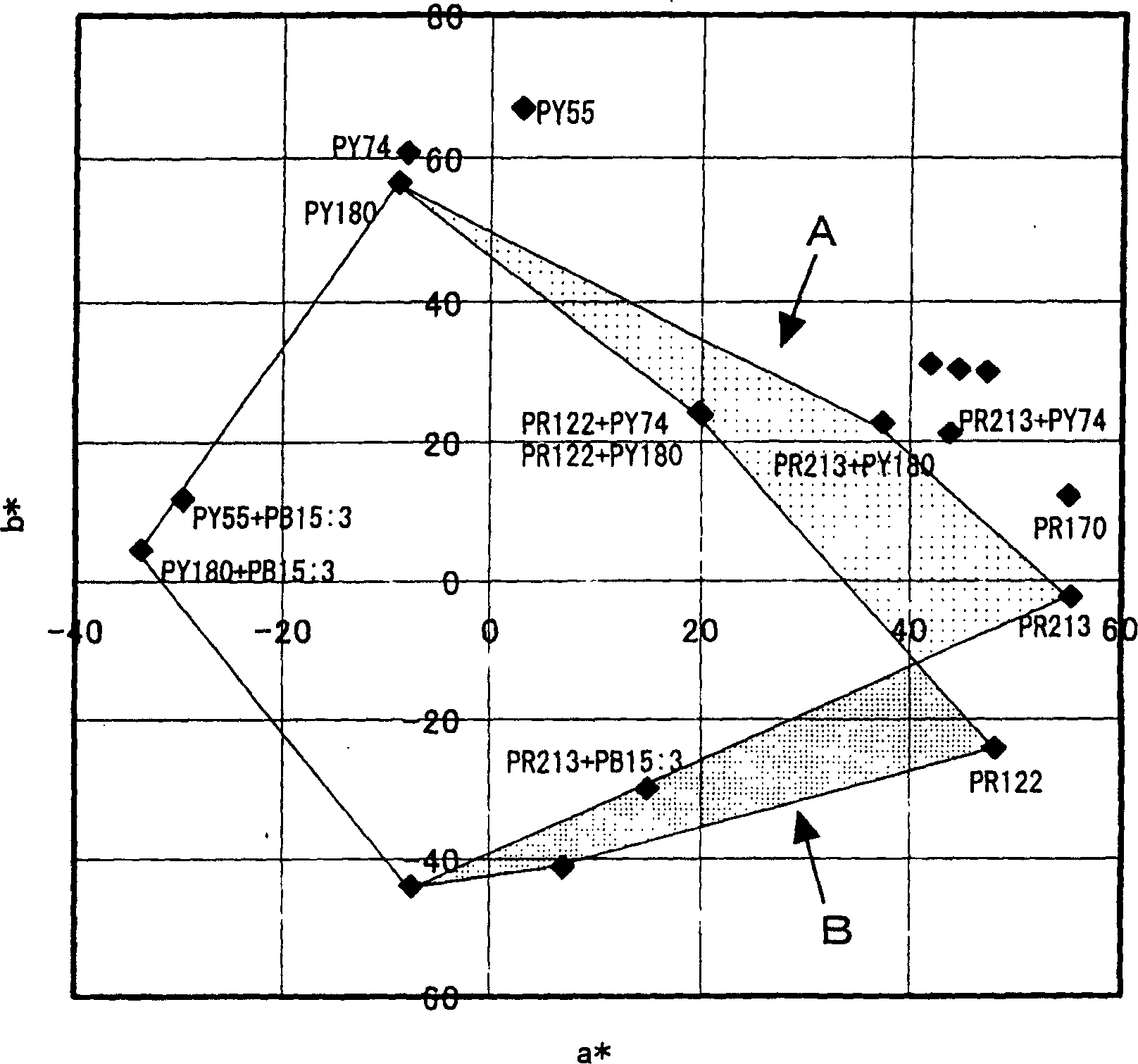

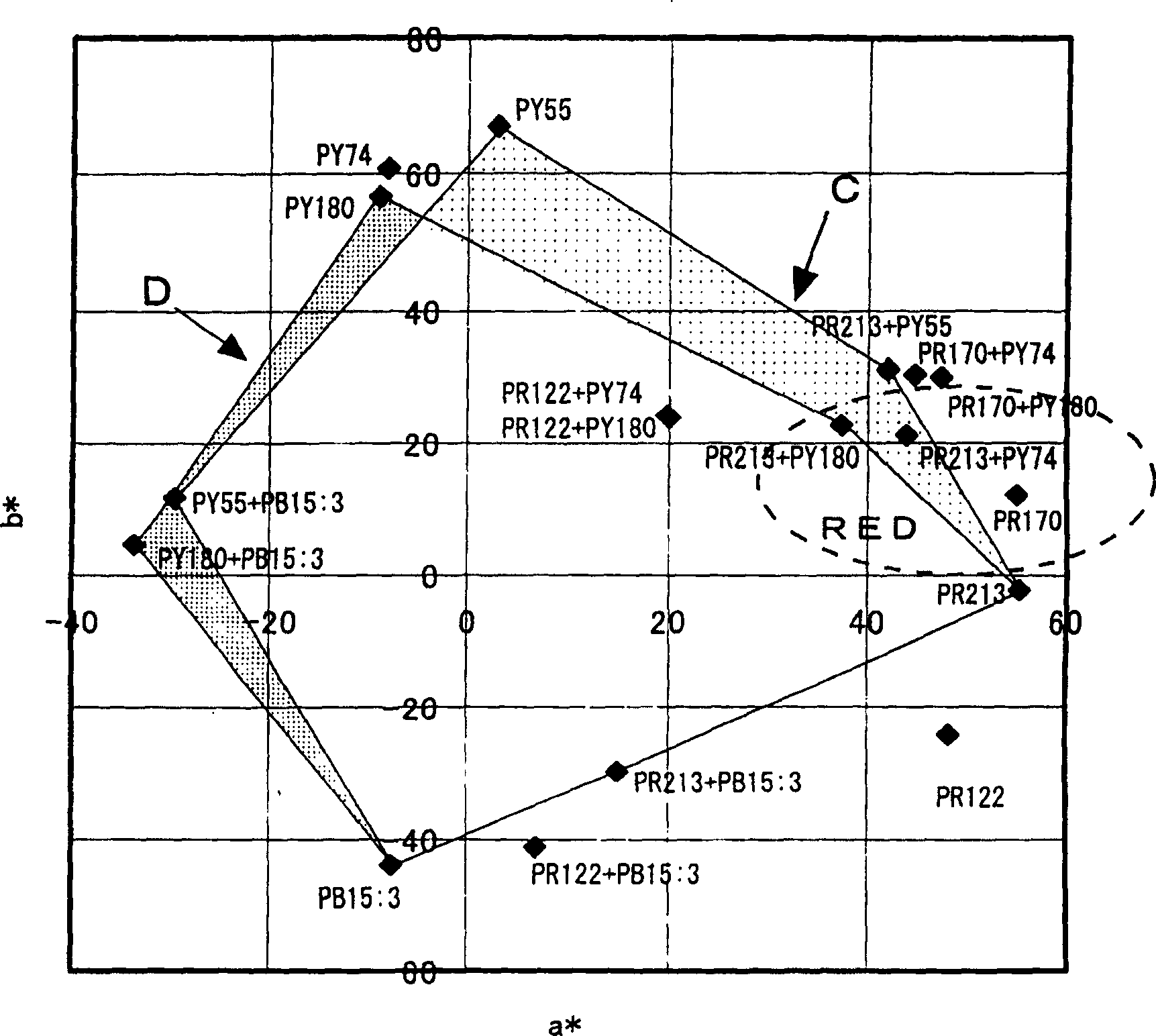

Image

Examples

Embodiment

[0042] The present invention will be described in detail by the following examples.

[0043] (1) Preparation of pigment ink

[0044] Fill the disperser (sand mill, Igarashi Machinery Co. Ltd. (Igarashi Machinery Co., Ltd.)) with glass beads or zirconium beads (1 mm diameter) with a diameter of 1 mm, followed by 10 wt % of C.I. Pigment Red 213 as a pigment, 35 wt % glycerin as a water solvent and balanced pure water were charged into the disperser, and then these mixtures were crushed for 3 to 4 hours. The product was centrifuged (10000 rpm, 30 minutes) to remove coarser particles. Adding the 4.0wt% water emulsion of the 10% aqueous solution of the acrylic resin emulsion to which the pH is adjusted to 8 to 10, the magenta ink (pigment concentration 10wt% in the volume average particle diameter of the dispersed pigment) in the range of 50nm to 200nm ).

[0045] The same inks were prepared using the inks listed in Table 1, resulting in three magenta inks, three yellow inks and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com