Wafer connector

A technology of connectors and wafers, which is applied in the direction of connection, parts of connection devices, incandescent lamps, etc., and can solve the problem of not scraping off the oxide layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

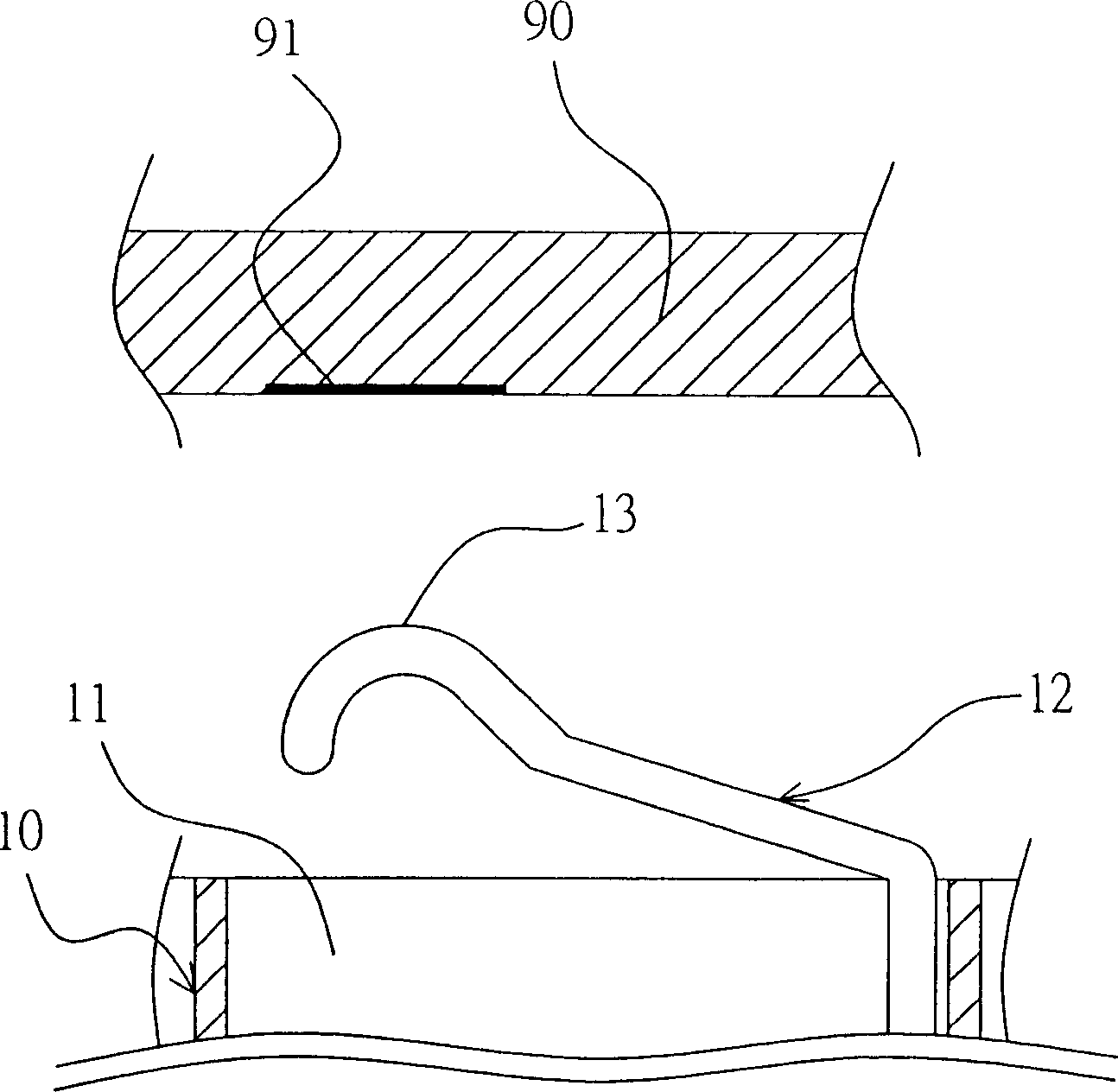

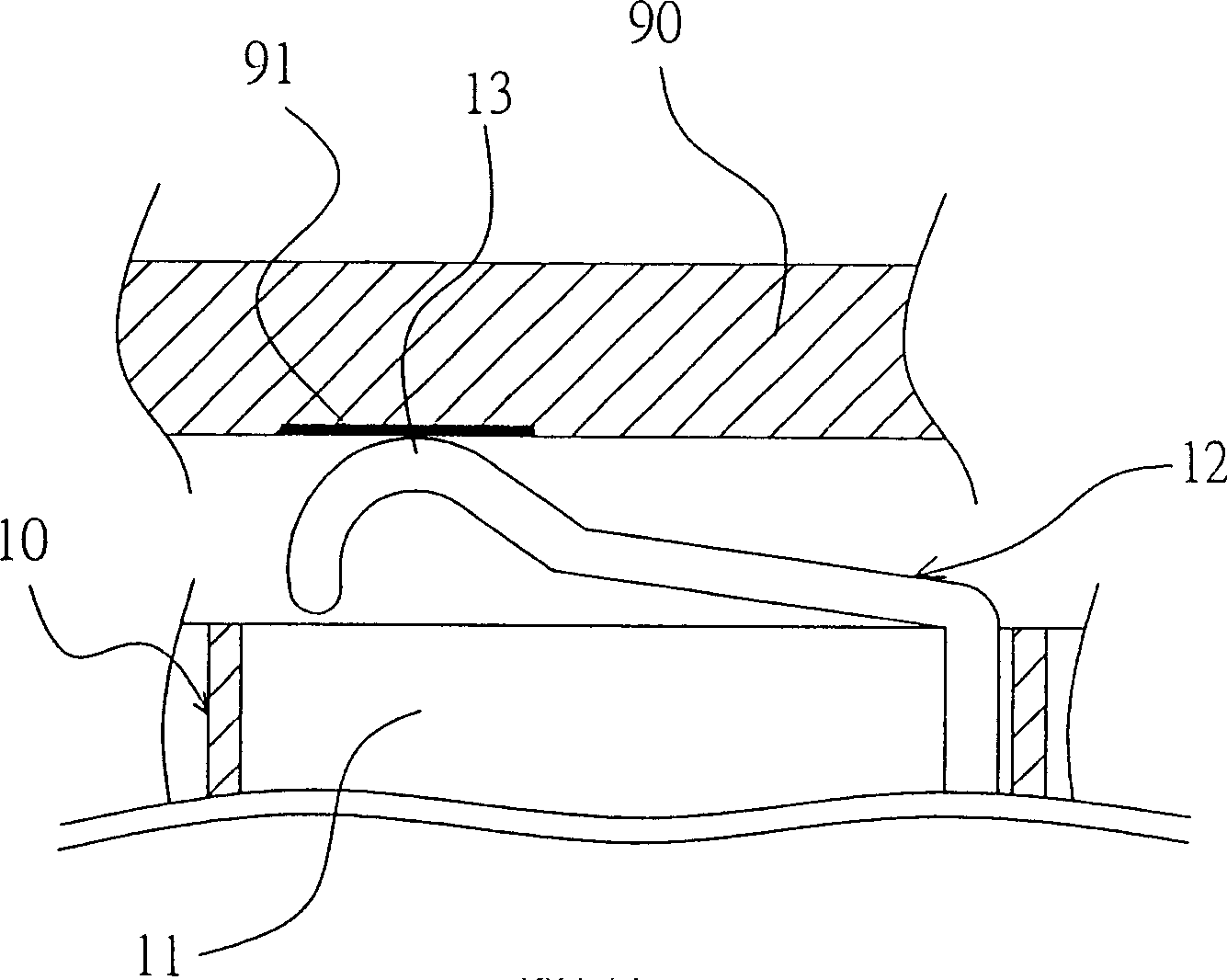

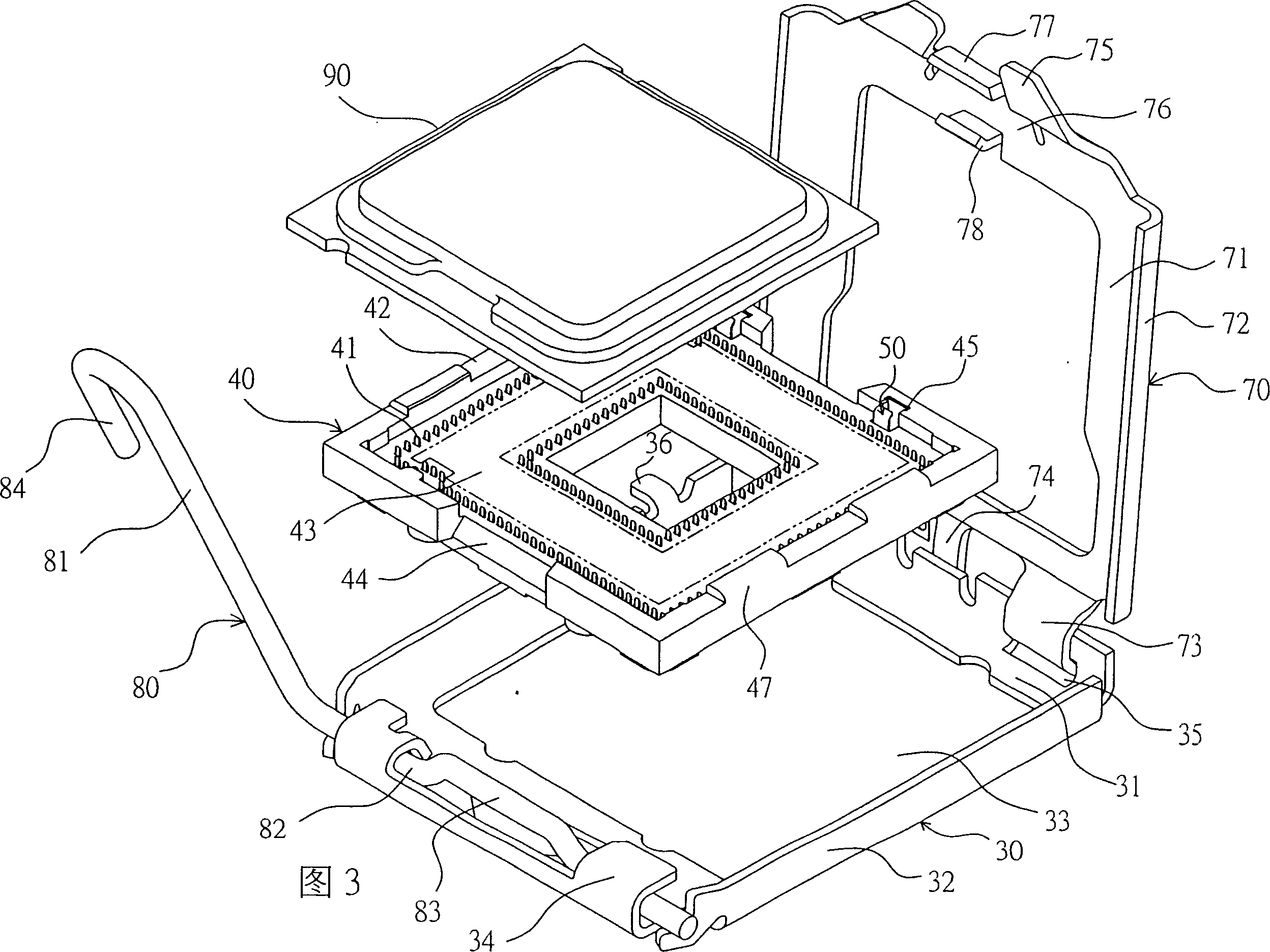

[0032] Please refer to Figure 3, Figure 4, Figure 5 and Figure 8 , the electrical connector of this embodiment includes: a base, an elastic device 50, several terminals 60, an upper cover 70, and a rocker 80, wherein:

[0033] The base includes a metal outer seat 30 and a plastic inner seat 40; the outer seat 30 is provided with a bottom surface 31 and two side walls 32, a hollow area 33 is formed in the center of the bottom surface 31, and a third A pivotal joint 34, and the rear end is provided with the second pivotal joint 35 that is hole-shaped, and the other side is provided with a clamping piece 36; Several terminal grooves 41 are arranged, and the periphery of its upper end is provided with upward flange 42 and surrounds a placement area 43 for placing wafer 90, and the front end flange of this placement area is provided with a gap 44, and the rear end is provided with two grooves 45, The upper ends of the flanges on both sides are provided with protruding bumps 47 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com