Anti-vibration impact type quartz crystal resonator

A quartz crystal and resonator technology, applied in impedance networks, electrical components, etc., can solve the problems of shortening the life of quartz crystals, chip tearing and breaking, and the stability of the effect is questionable, so as to ensure normal working performance, assembly efficiency and service life improvement. , The effect of easy and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

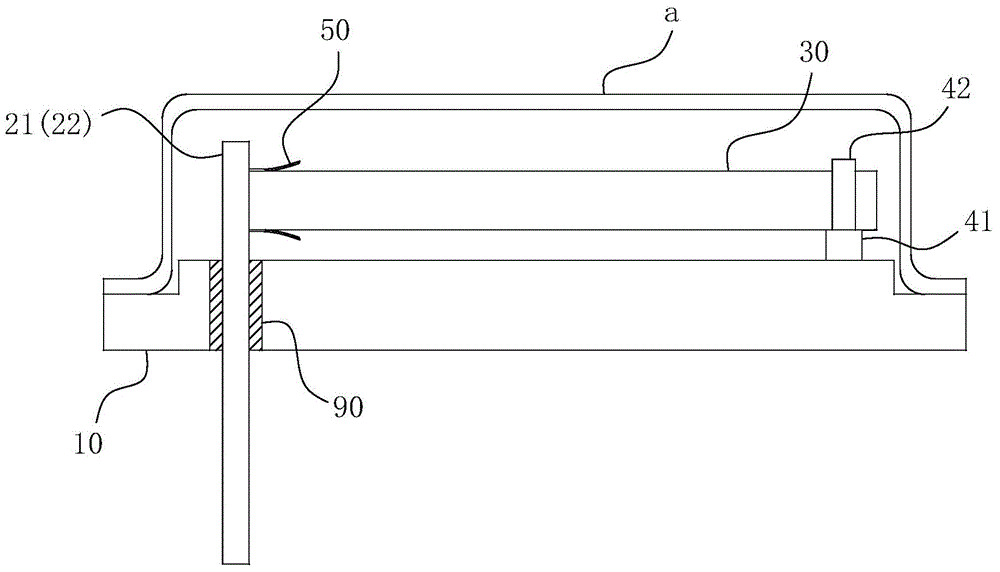

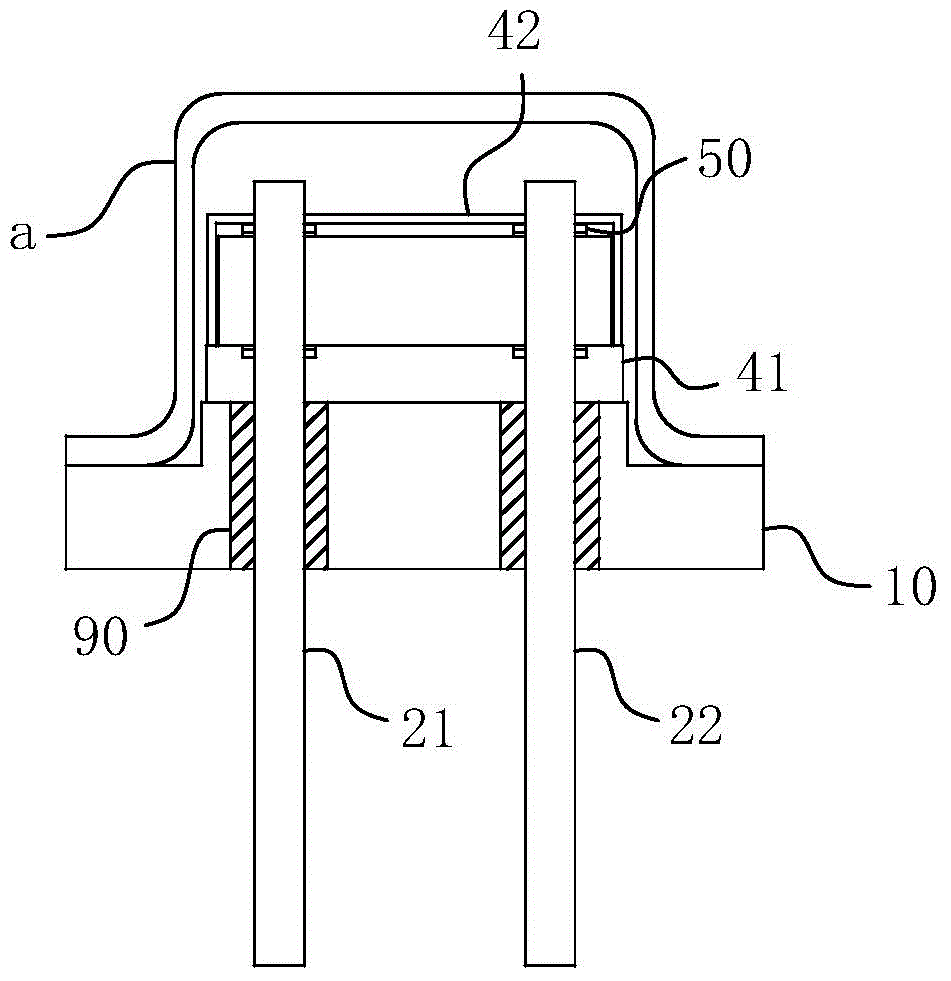

[0032] For ease of understanding, combined here Figure 1-6 , the specific implementation structure of the present invention is further described as follows:

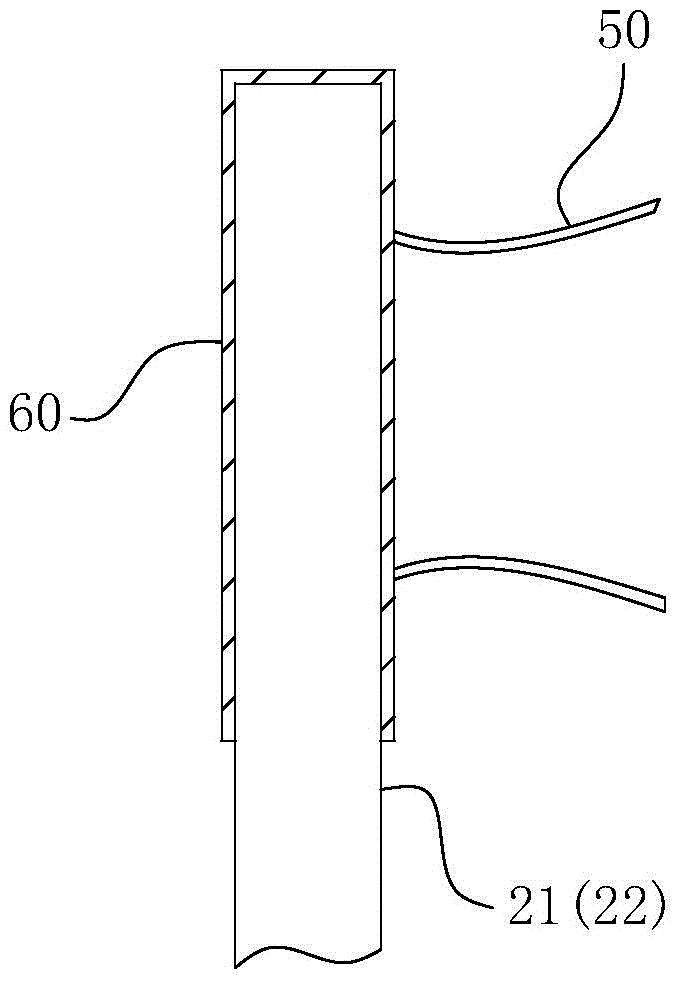

[0033] The specific structure of the present invention is as Figure 1-2 As shown, it includes a base 10 covered with a casing a, and two mounting holes are opened on the same side of the base 10 for two lead posts to pass through, and quartz insulators are sleeved in the two mounting holes, and the two lead wires The upper ends of the columns are respectively provided with jaw-shaped clamping parts for fixing the same side of the quartz wafer 30 and connecting with the electrodes between the wafers. The jaw-shaped clamping part is composed of two elastic clips 50 arranged in parallel up and down along the same lead column, so as to utilize the high-precision matching distance of the elastic clips 50 and match its own elastic clamping force to finally realize the quartz The cantilever fixation effect on the same side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com