Automatic electricity conversion apparatus for rubber-tyred crane transmission

A technology of crane transfer and tire crane, which is applied in the direction of transportation, packaging, and load suspension components, etc. It can solve problems such as poor contact of the electric trolley, wear and tear of the trolley line and the trolley, and reduce the protection level of the trolley line. To achieve the effect of guaranteeing performance, improving connection performance and improving protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

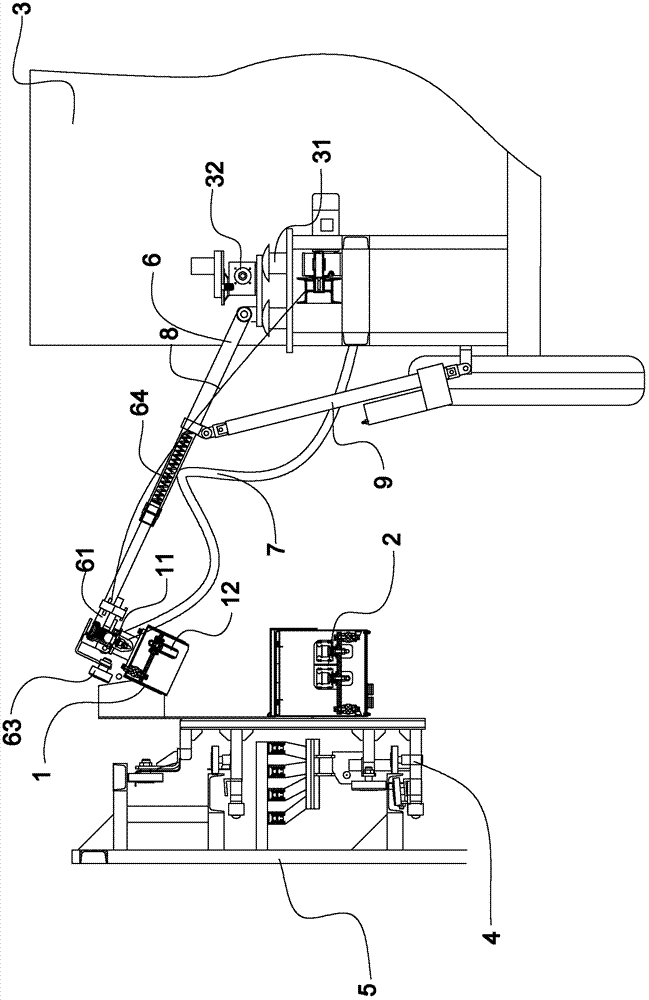

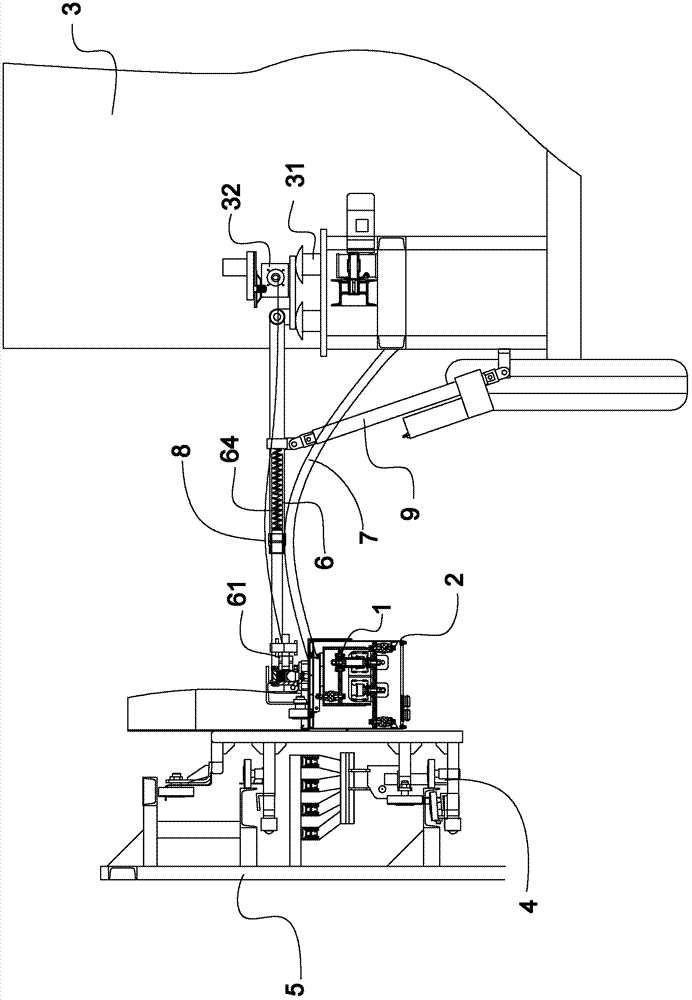

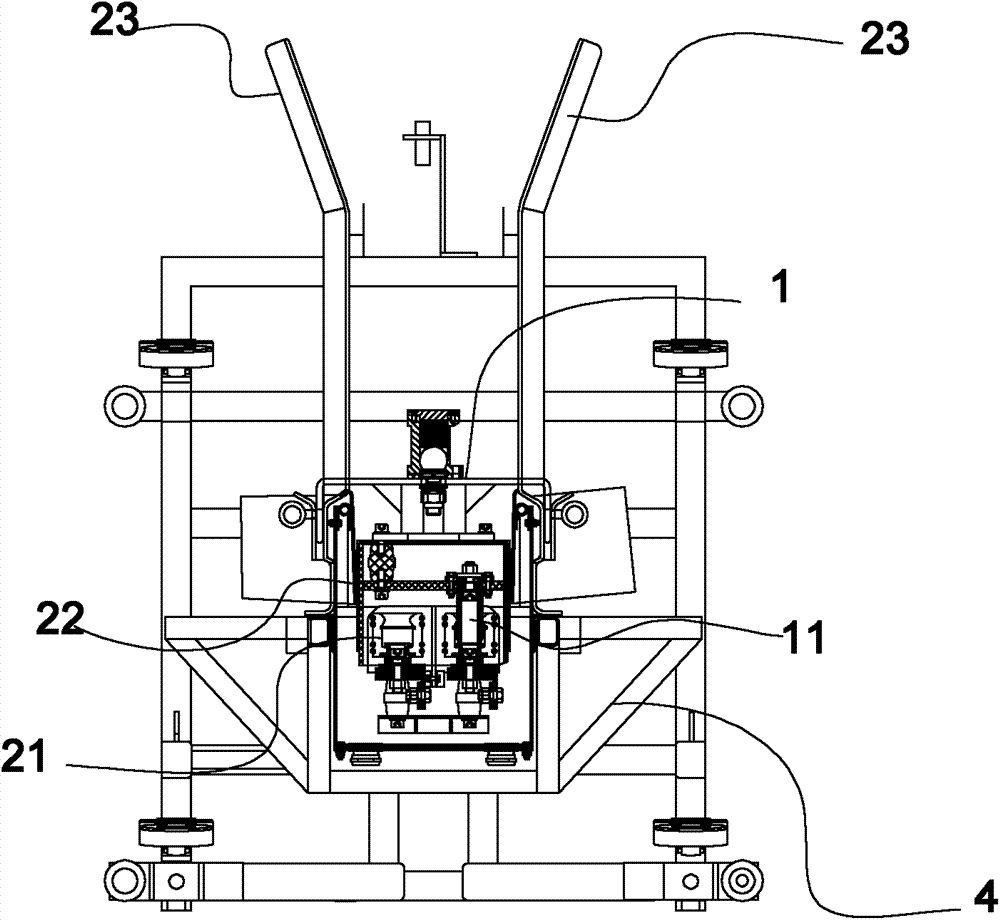

[0021] Such as Figure 1-5 As shown, the automatic power exchange device of the tire crane includes a trolley line 5, a power-taking trolley 4 that is connected to the trolley line 5 and can move left and right along the trolley line, and the power-taking trolley 4 There is a socket 2 on the top, and a movable plug 1 is set on the tire crane 3. The plug 1 matches the socket 2 on the power-taking trolley 4 and after being inserted into the socket 2, the tire crane takes power from the trolley line 5 . When transitioning, as long as the plug 1 is pulled out from the socket 2, and then the plug 1 is inserted into the socket 2 on the trolley line of another venue after entering another venue, automatic transition can be realized.

[0022] Such as figure 1 , 2 As shown, the tire crane 3 is provided with a cable 7 connected to the plug 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com