Pneumatic radial tire

A technology for radial tires and tires, applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc., which can solve the problems of increased bite and reduced high-speed durability, so as to prevent damage, improve high-speed durability, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

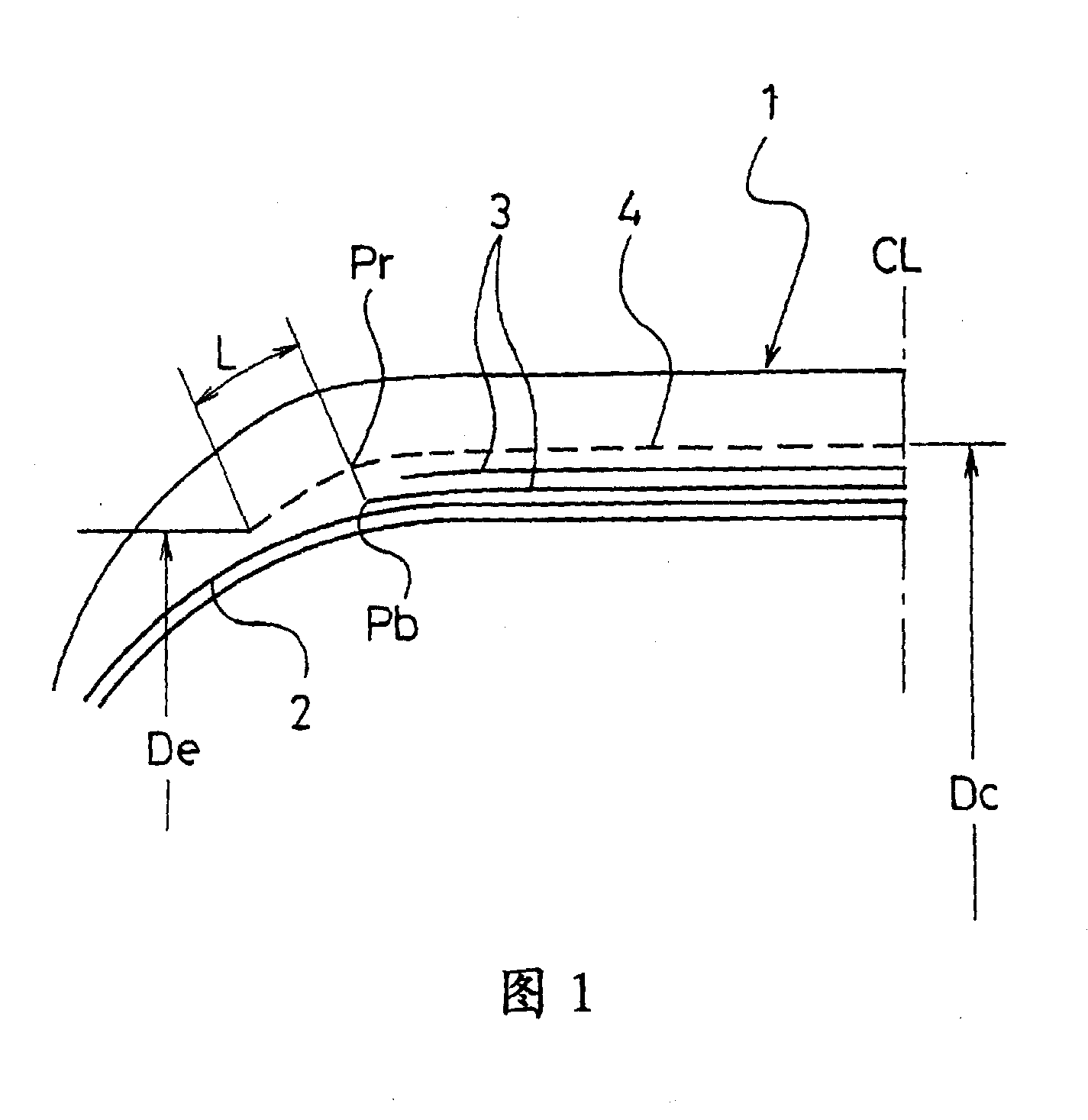

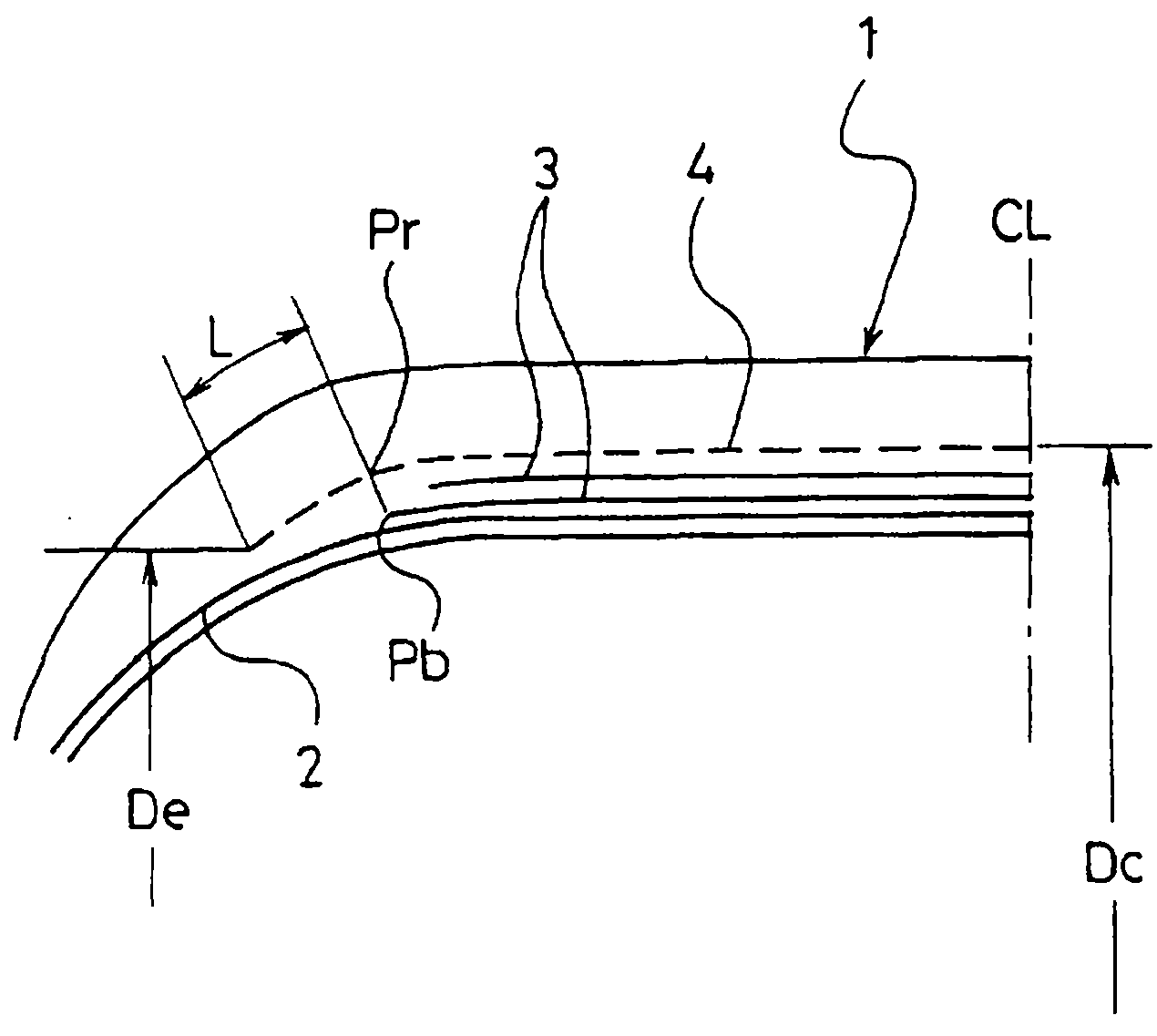

[0030] Make 12 kinds of pneumatic radial tires (embodiment 1~8, conventional example 1,2, comparative example 1~2): its common condition is that tire size is 205 / 50R17, has figure 1 The aspect of the tire structure using polyethylene terephthalate yarn as the reinforcing cord of the belt reinforcing layer; and the length L protruding from the end of the belt reinforcing layer with the largest width after vulcanization molding ( mm) and the intermediate elongation E (%) of the reinforcing cord at a load of 67 N are different as shown in Table 1.

[0031] For these 12 kinds of pneumatic radial tires, road noise and high-speed durability were measured by the following experimental method, and the results were made into an index with the measurement result of the tire of Conventional Example 1 as 100, and were shown in Table 1 (index value Larger means better). As can be seen from the results in Table 1, the tires of Examples 1 to 8 are all excellent in both road noise and high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com