Protective part for the leading edge of a blade

一种保护件、前缘的技术,应用在叶片的支承元件、泵元件、用于弹性流体的泵送装置的部件等方向,能够解决保护件重量大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

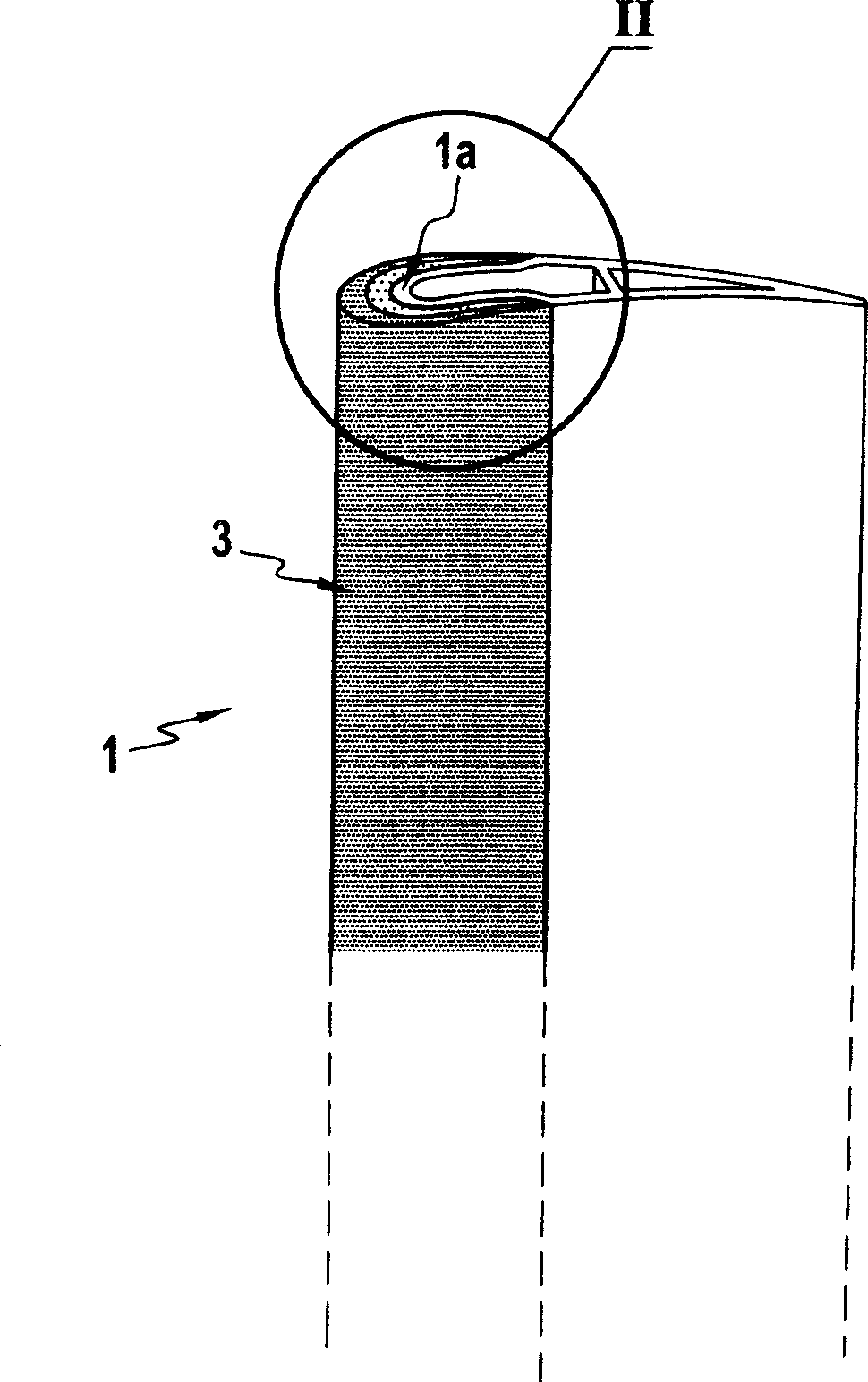

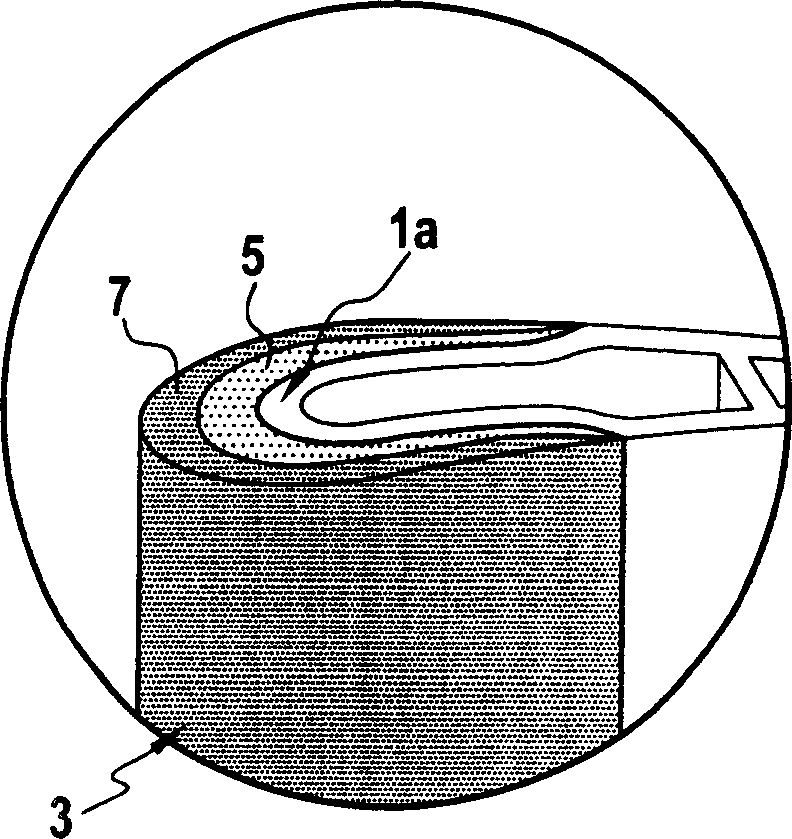

[0016] figure 1 and figure 2 The airfoil portion of a turbine blade 1 is shown, the leading edge 1a of the blade 1 being covered with a protective element 3 according to the invention.

[0017] The cross-section of the protective element 3 is substantially U-shaped, enabling it to be placed across the leading edge 1 a of the blade 1 . Part 3 consists of two layers, an inner layer 5 and an outer layer 7 . The outer layer 7 is made of aluminum alloy reinforced with SiC particles, while the inner layer 5 is the same grade of aluminum alloy but not reinforced with SiC. For aerospace applications, the 7000 series aluminum alloys are preferred.

[0018] Of course, the protective part can have more than two layers, and the content of SiC particles in each layer gradually increases from the inside to the outside. Thus, in an embodiment not shown, the protector has four layers C 1 、C 2 、C 3 、C 4 , inner layer C 1 The content of SiC in is zero, C 2 The content in is about 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com