Slide sand-slope deep sand-fixation method

A sand-sliding slope and deep technology, applied in the field of deep sand-fixing of sand-sliding slopes, can solve problems such as unreasonable and imperfect structures, and the height and section size of the sand retaining wall cannot be accurately determined, so as to achieve increased stability and accelerated soil transformation , Conducive to the restoration and reconstruction of plant ecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The step that the present invention implements this deep sand-fixing method is:

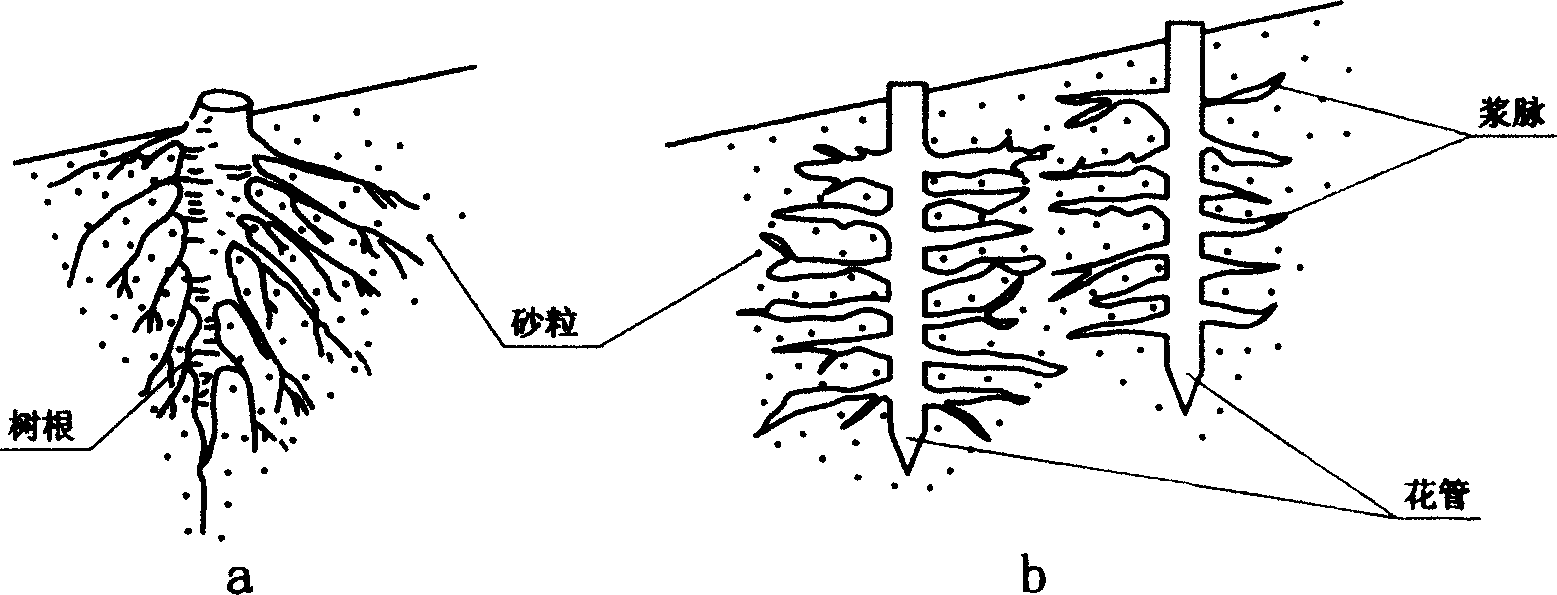

[0018] (1) Conduct investigation and survey on the sand slide slope that needs deep sand consolidation, determine the material composition, structure and other characteristics of the sand slope, the thickness of the sand slope and the sand consolidation depth, and carry out design analysis and calculation. image 3 It is a schematic diagram of the sand-consolidation of the flower tube micro-root pile of the present invention, wherein a is a sketch of the actual sand-fixation of the tree root, and b is a schematic diagram of the sand-consolidation design of the tree root pile.

[0019] (2) Production of flower tubes

[0020] ①Pipe selection: After testing and demonstration, 50~55mm PVC pipe can be selected (the rigidity of PVC pipe can meet the requirements of grouting pressure and has the characteristics of anti-corrosion, no rust, and low price).

[0021] ② Drilling in the grouting sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com