Checkscrew built in spring lamination

A spring card, spring card nut technology, applied in the direction of screws, nuts, bolts, etc., can solve problems such as limitations in the use of common materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

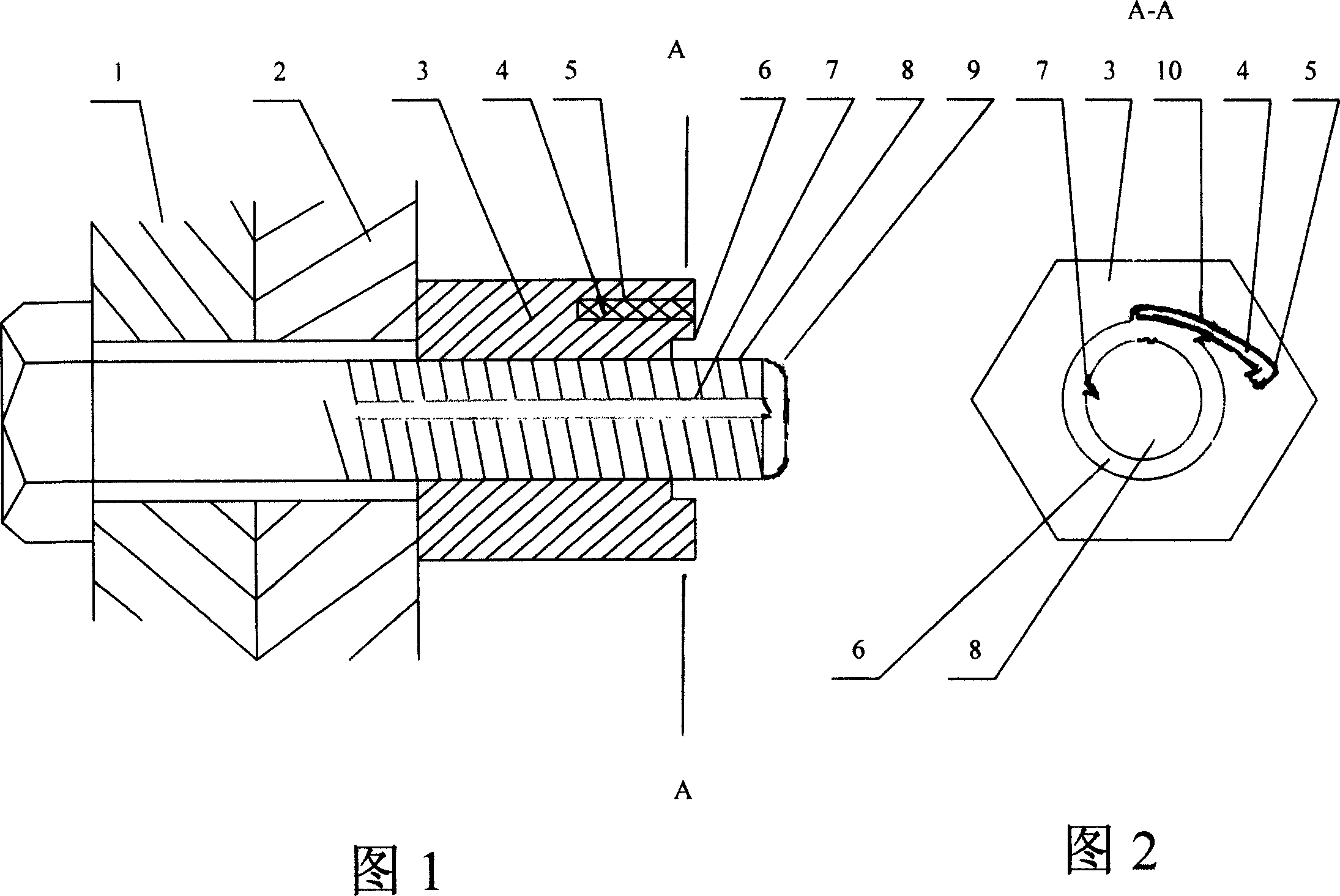

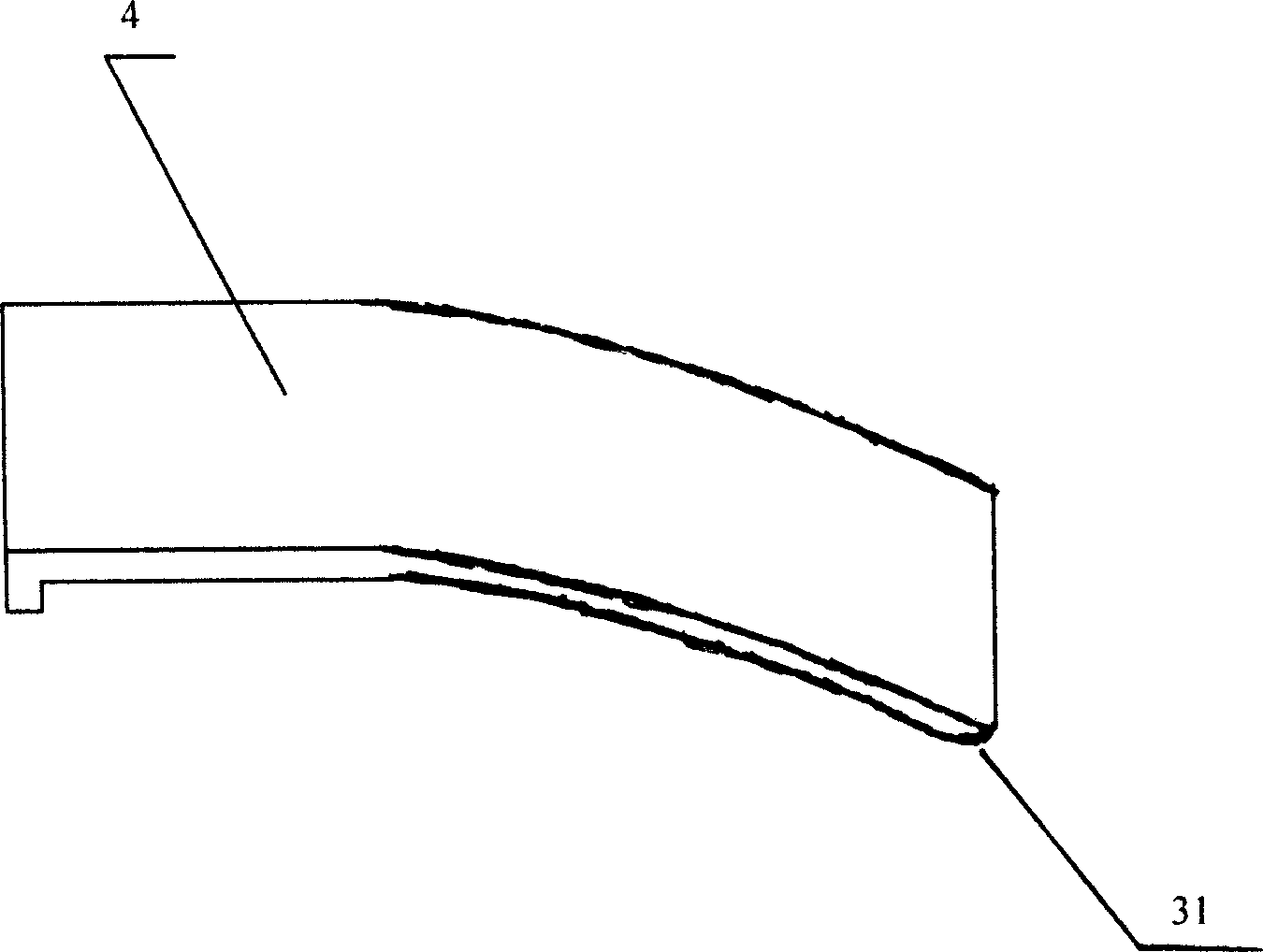

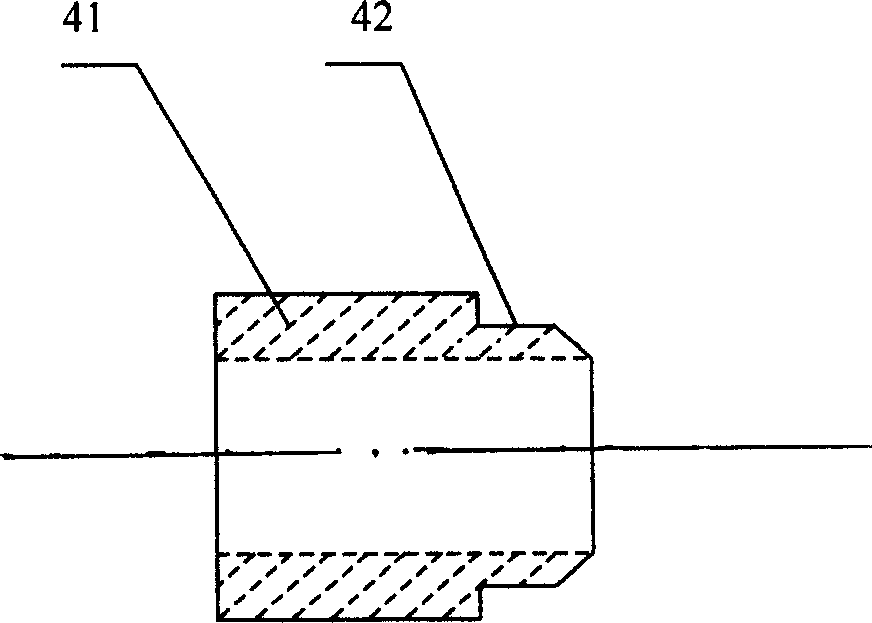

[0019] As shown in FIG. 1 and FIG. 2 , a lock screw with a built-in spring card according to an embodiment of the present invention includes a slotted bolt 8 and a clip nut 3 . Position the slotted bolt 8 on the engineering part 1 and the engineering part 2, and tighten the clip nut 3 on the slotted bolt 8 according to the end of the spring card equipped with the back to the slotted bolt 8. The thread of the slotted bolt 8 is provided with a groove 7 . The bullet nut 3 faces away from the end of the slotted bolt 8, and is provided with a bullet groove 4 and a bullet 5 contained therein, and a groove 9 connected with the bullet groove 4, and the bullet nut 3 faces away from the grooved bolt. The screw thread at one end of 8 is provided with a withdrawal groove 6.

[0020] As can be seen from the embodiment, when the spring card nut 3 is screwed with the slotted bolt 8 against the slotted bolt 8 at the end of the spring card, the exposed part of the bullet 4 in the bullet slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com