Grip

A grip and resin technology, applied in the field of grips, can solve the problems of loss of appearance, grip, grip, surface is difficult to be heated, power consumption increases, etc., to achieve improved appearance, easy insertion, good installation and durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

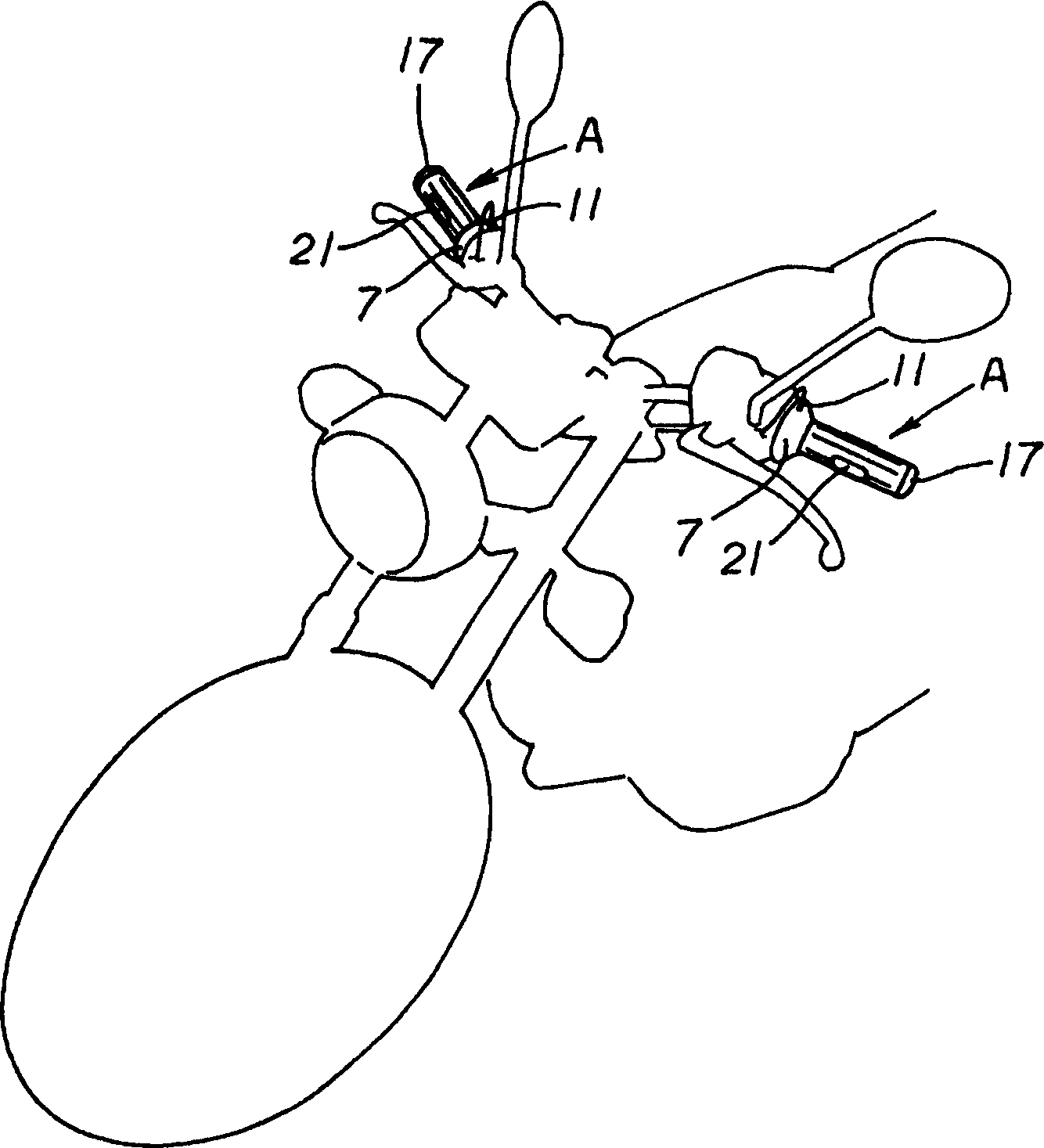

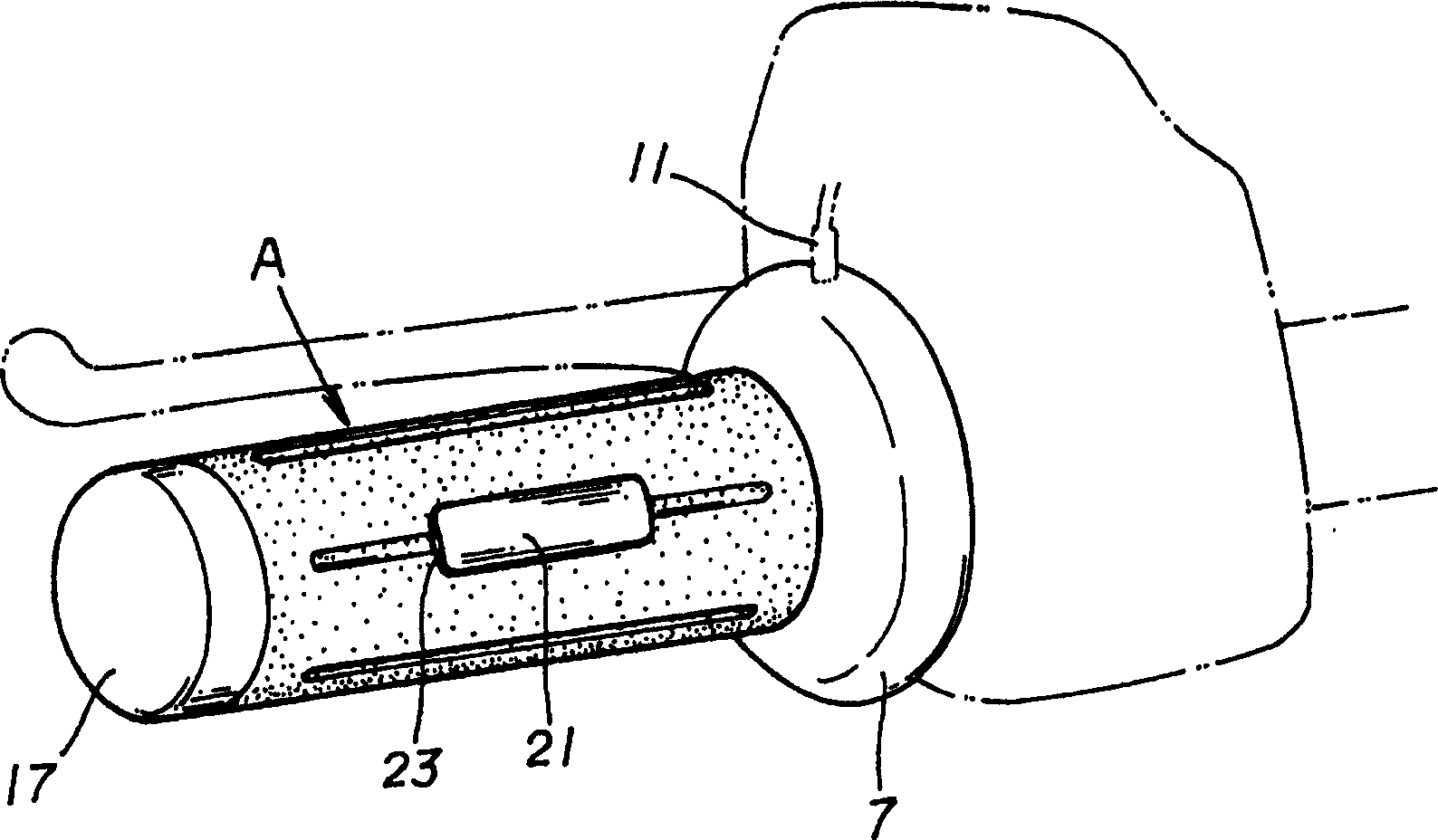

[0047] Hereinafter, preferred embodiments of the present invention (how to carry out the invention) will be described. First show and explain the effect of the present invention according to accompanying drawing.

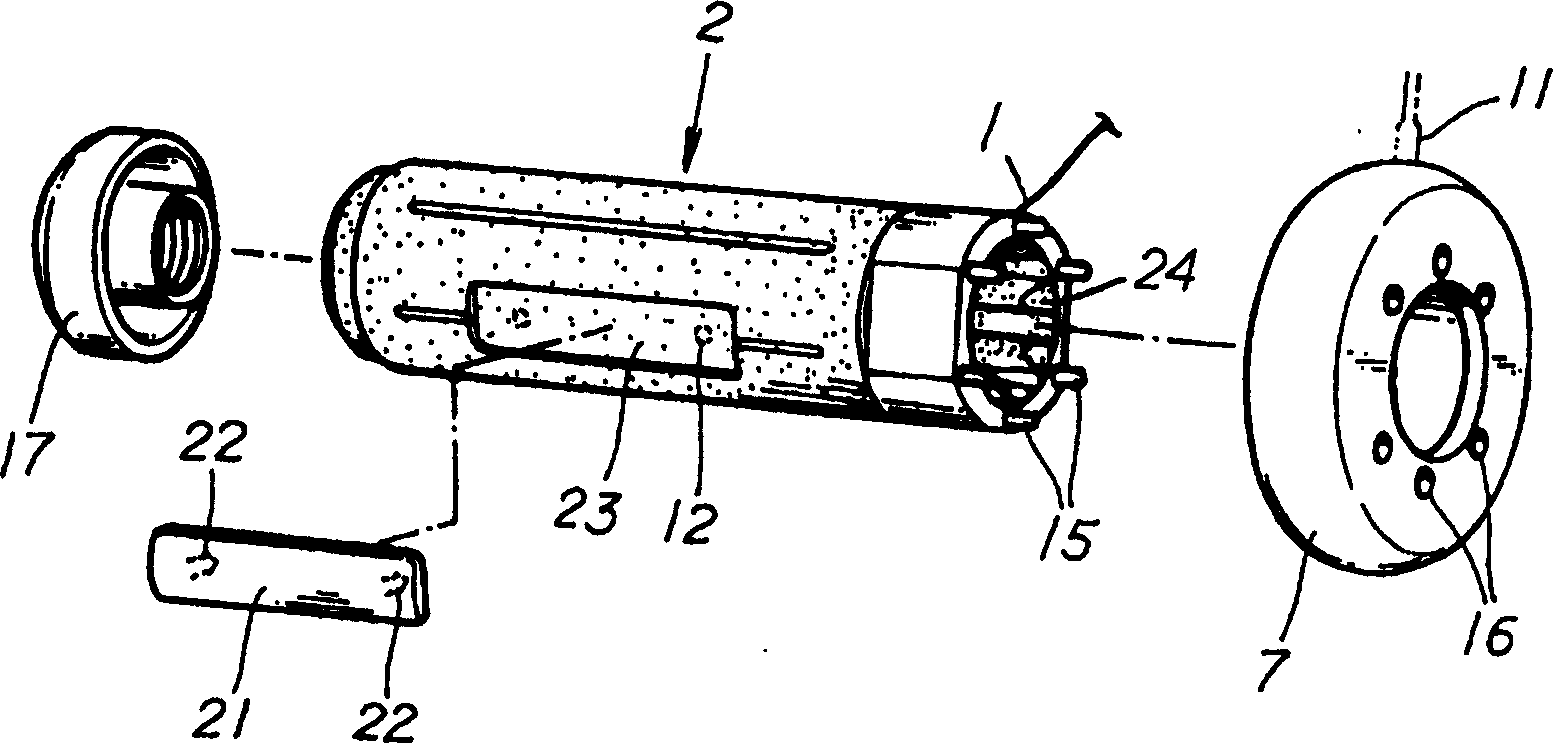

[0048] Firstly, the technical solutions 1 to 6 of the present invention characterized by the installation structure of the plates 21 are described.

[0049] A resin layer is formed on the surface and the inside of the inner member 2, and the inner member 2 is provided with a resin flow hole 12 connecting the resin on the surface and the inside, and the resin flow hole 12 is used as a mounting hole. An insertion rod 22 is attached to the plate 21 , and the insertion rod 22 on the plate 21 is inserted into the resin flow hole 12 to lock and fix the plate 21 to the surface of the handle body A.

[0050] For example, when the vehicle is a motorcycle, the handlebar tube or accelerator controller tube becomes the mounting part 4 of the grip, and the internal member 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com