End structure of bypass blast-variable air conditioner

A variable air volume and bypass type technology, which is applied to the air outlet device of the central air conditioner and the terminal structure field of the bypass type variable air volume air conditioner. It can solve the problems of large noise, complicated installation and operation of the air volume adjustment mechanism, etc., and achieve increased noise and energy saving. The effect is obvious and the static pressure is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

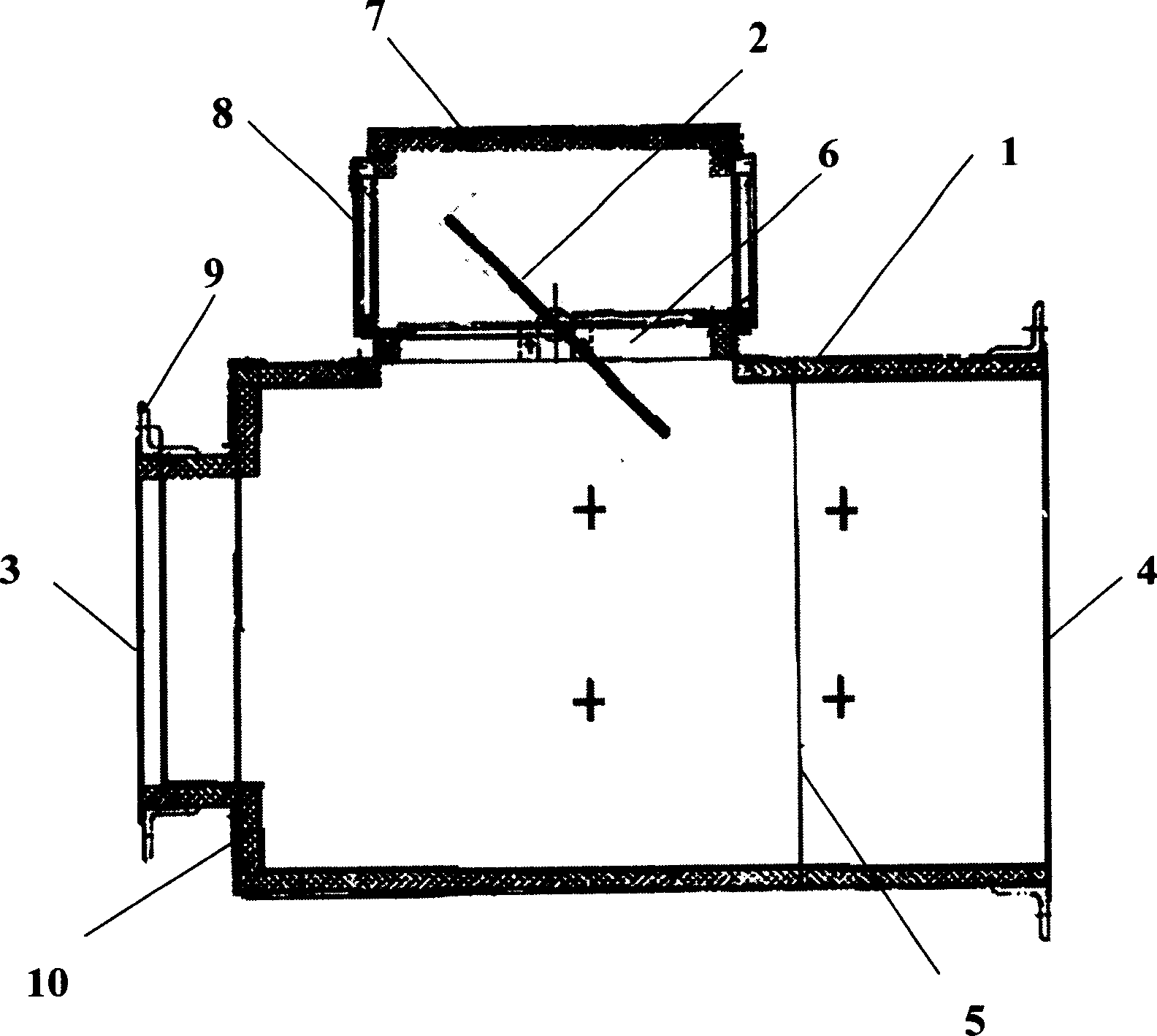

[0013] Such as figure 1 As shown, the terminal structure of the bypass-type variable air volume air conditioner of the present invention is composed of a sealed cabinet 1 and a damper 2, wherein one end of the sealed cabinet 1 is provided with an air inlet 3, and the other end of the sealed cabinet 1 is An air supply port 4 is provided, a diffuser plate 5 is provided in the cabinet between the air inlet 3 and the air supply port 4, and a return air port 6 is provided in one side of the sealed cabinet 1, the A side cabinet 7 is arranged outside the air return port 6, the side cabinet 7 is fixedly connected to the side of the sealed cabinet 1, the inner cavity of the side cabinet 7 communicates with the return air port 6, the The air valve 2 is arranged in the air return port 6, and the two ends of the side cabinet 7 are respectively provided with an air outlet 8.

[0014] Further, the air valve 2 is electrically connected with a controller, the controller is arranged in an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com