Disc drive apparatus

A disk drive, optical disk drive technology, applied in the configuration/installation of heads, digital recording/reproduction, instruments, etc., can solve problems such as dependence, affecting controller capabilities, mechanical vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

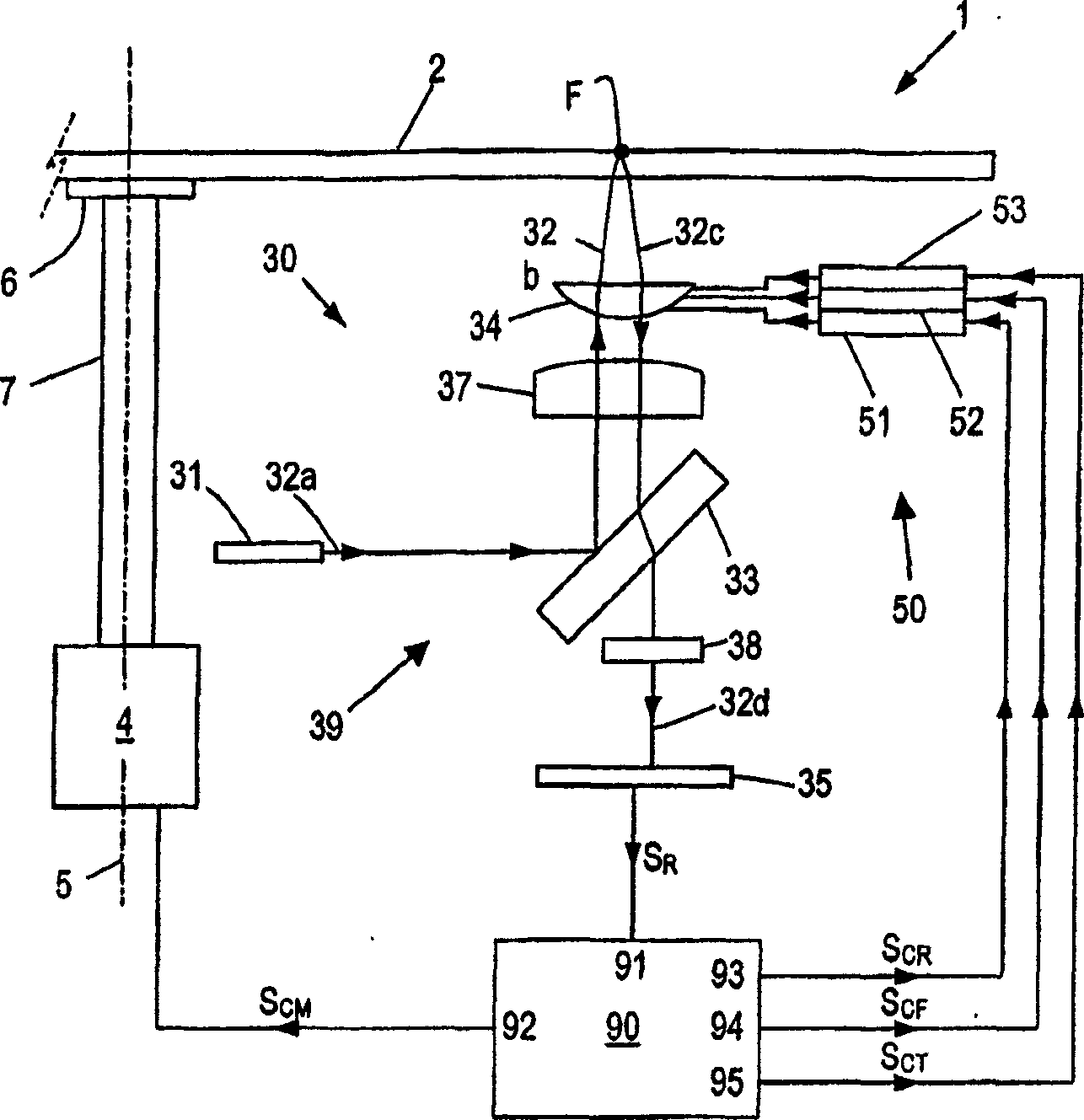

[0032] Figure 1A An optical disc drive device 1 is schematically shown, adapted to store information on, or to read information from, an optical disc 2, usually a DVD or CD. In order to rotate the disk 2 , the disk drive device 1 comprises a motor 4 fixed to a frame (not shown for simplicity), said frame defining an axis of rotation 5 .

[0033] The disk drive apparatus 1 also includes an optical (optic) system 30 for scanning the track of the disk 2 with a light beam (not shown). More specifically, in Figure 1A In the exemplary arrangement shown, the optical system 30 comprises beam generating means 31 , typically a laser, such as a laser diode, arranged to generate a beam 32 . In the following, the different parts of the light beam 32 along the optical (path) path 39 will be indicated with the letters a, b, c etc. appended to the reference number 32 .

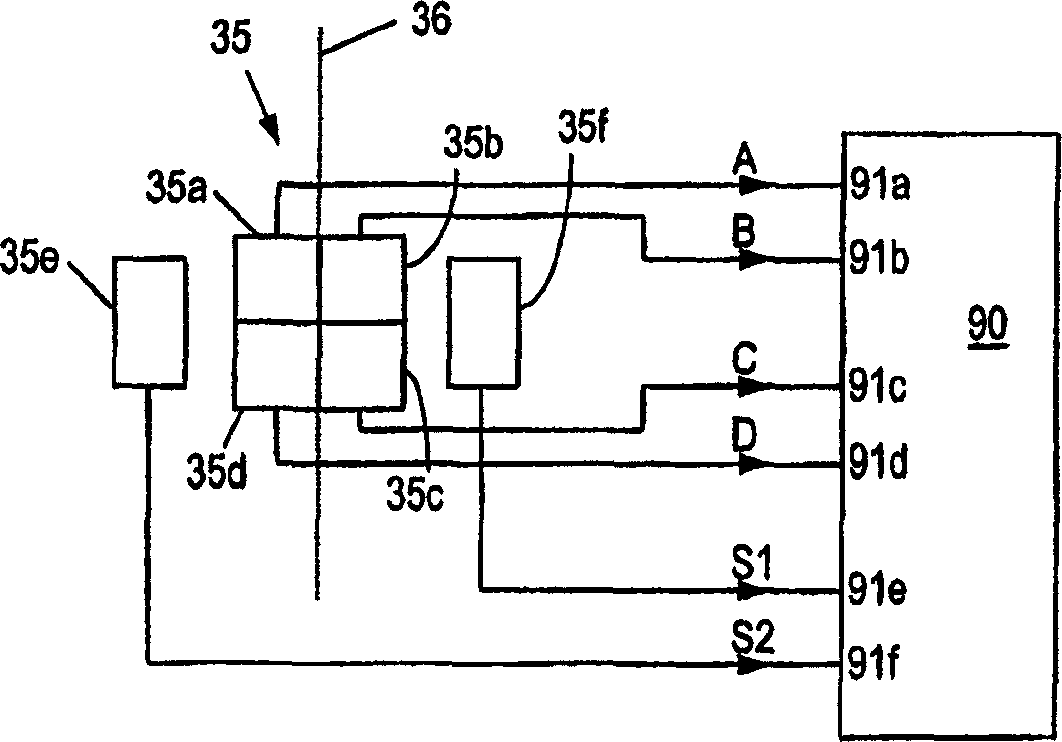

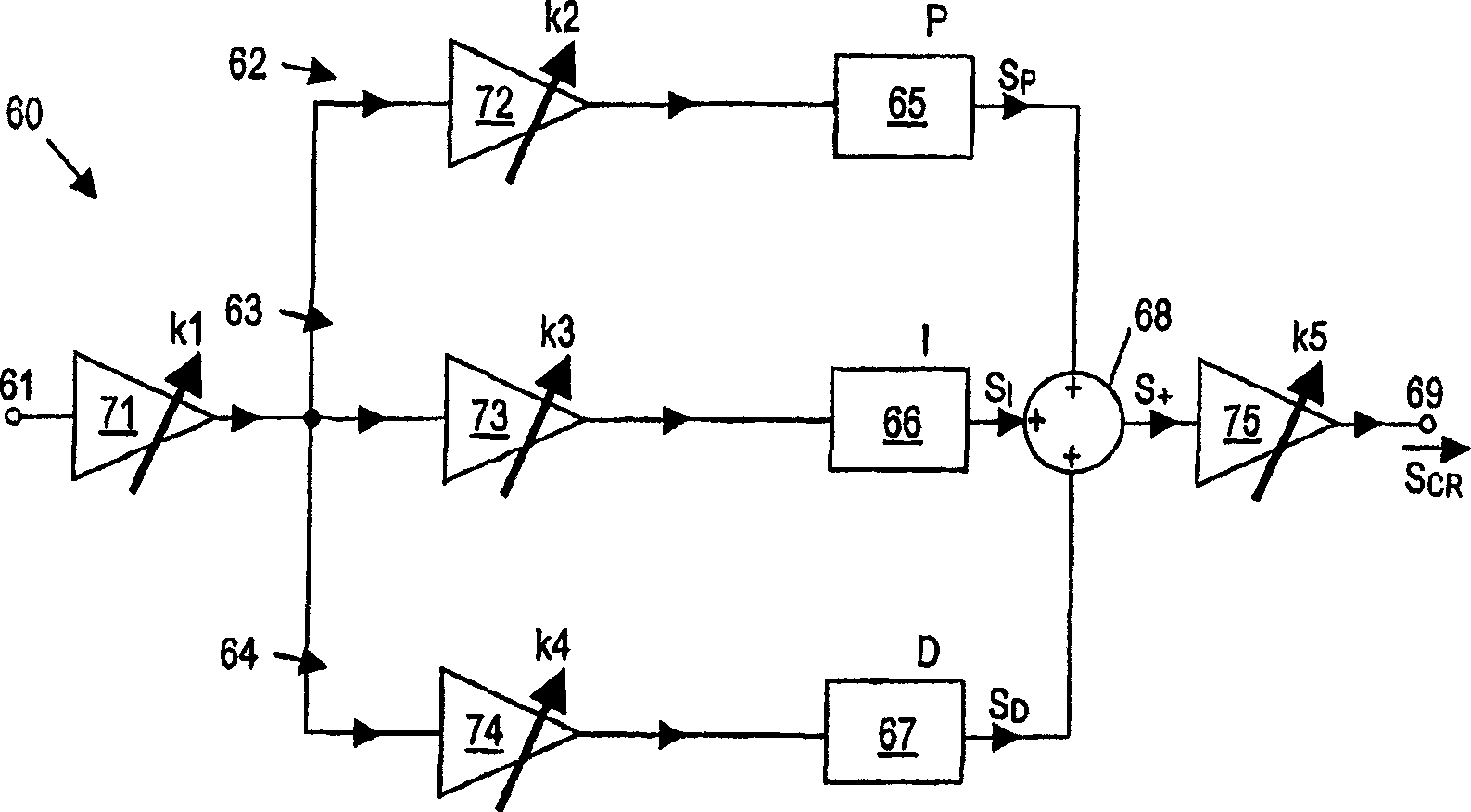

[0034] The light beam 32 passes through a beam splitter 33 , a collimator lens 37 and an objective lens 34 to reach (bea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap