Operation mechanism

A technology of operating mechanism and operating part, applied in the direction of contact operating mechanism, contact operating parts, mechanical equipment, etc., can solve the problems of difficulty in arousing the desire to buy, lack of novelty, and monotonous appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further describe the present invention in detail, preferred modes for implementing the present invention will be described below with reference to the accompanying drawings.

[0020] Implementation form 1:

[0021] Embodiment 1 of the present invention will be described below.

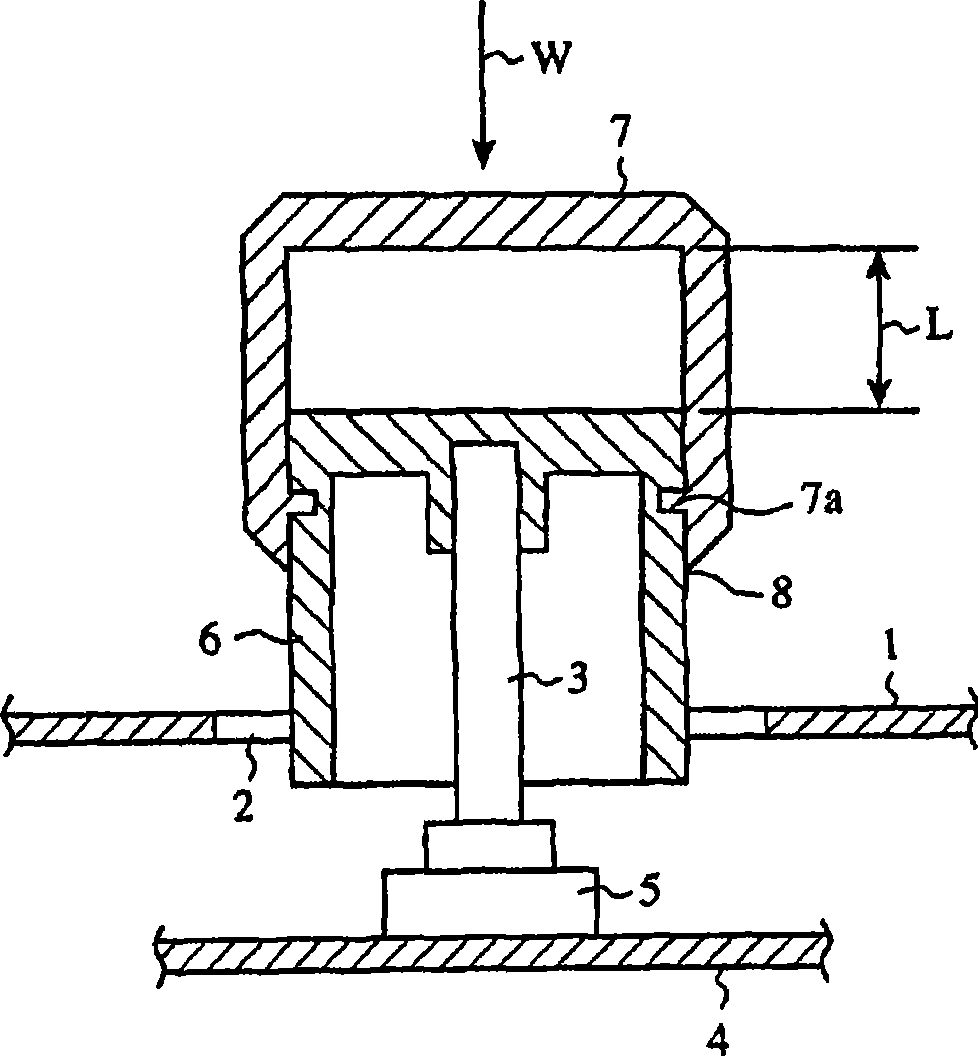

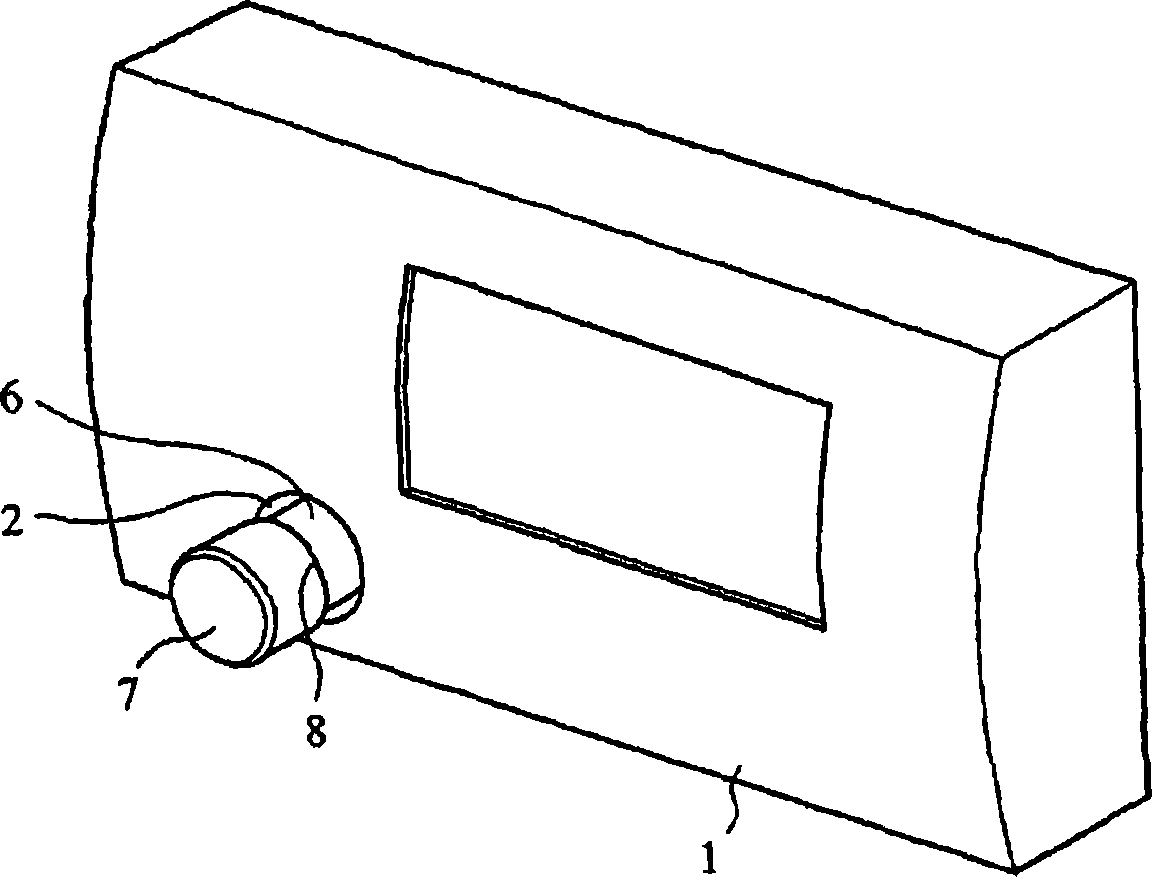

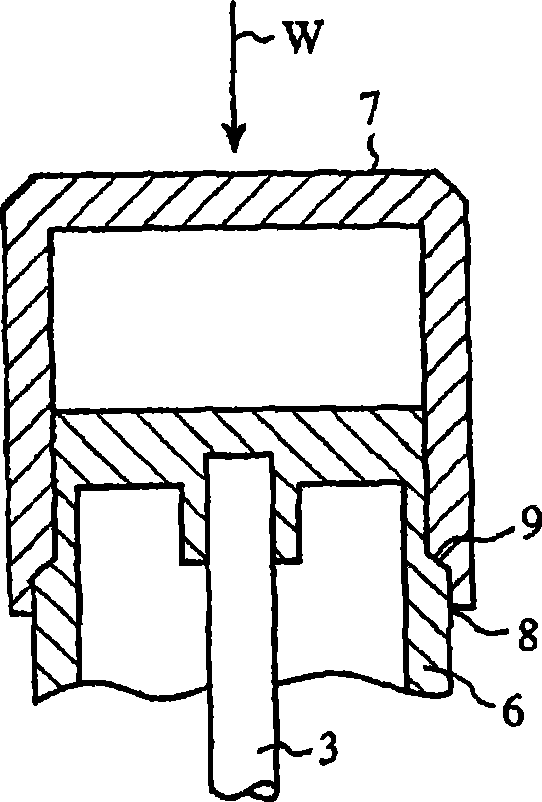

[0022] figure 1 In the front panel 1, a through hole 2 larger than the outer diameter of the operation part is formed, and an operation shaft 3 is provided in the through hole 2. The operating shaft 3 is integrally formed with an operating device 5 fixed to a base plate 4 arranged inside the front panel 1 . The operating shaft 3 can be moved in the axial direction and can be rotated. For example, a push-in encoder can be illustrated as the operating device 5 . In addition, the axial movement operation of the operation part can be switched on and off, and the volume can be adjusted by the rotation operation of the operation part. The front panel 1 may be a front panel of a vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com