Fracture mechanics measuring method for steel structure bridge life

A technology of fracture mechanics and measurement method, which is applied in the field of steel structure bridges, can solve problems such as inaccuracy and unreliability, and achieve the effect of ensuring accuracy and structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

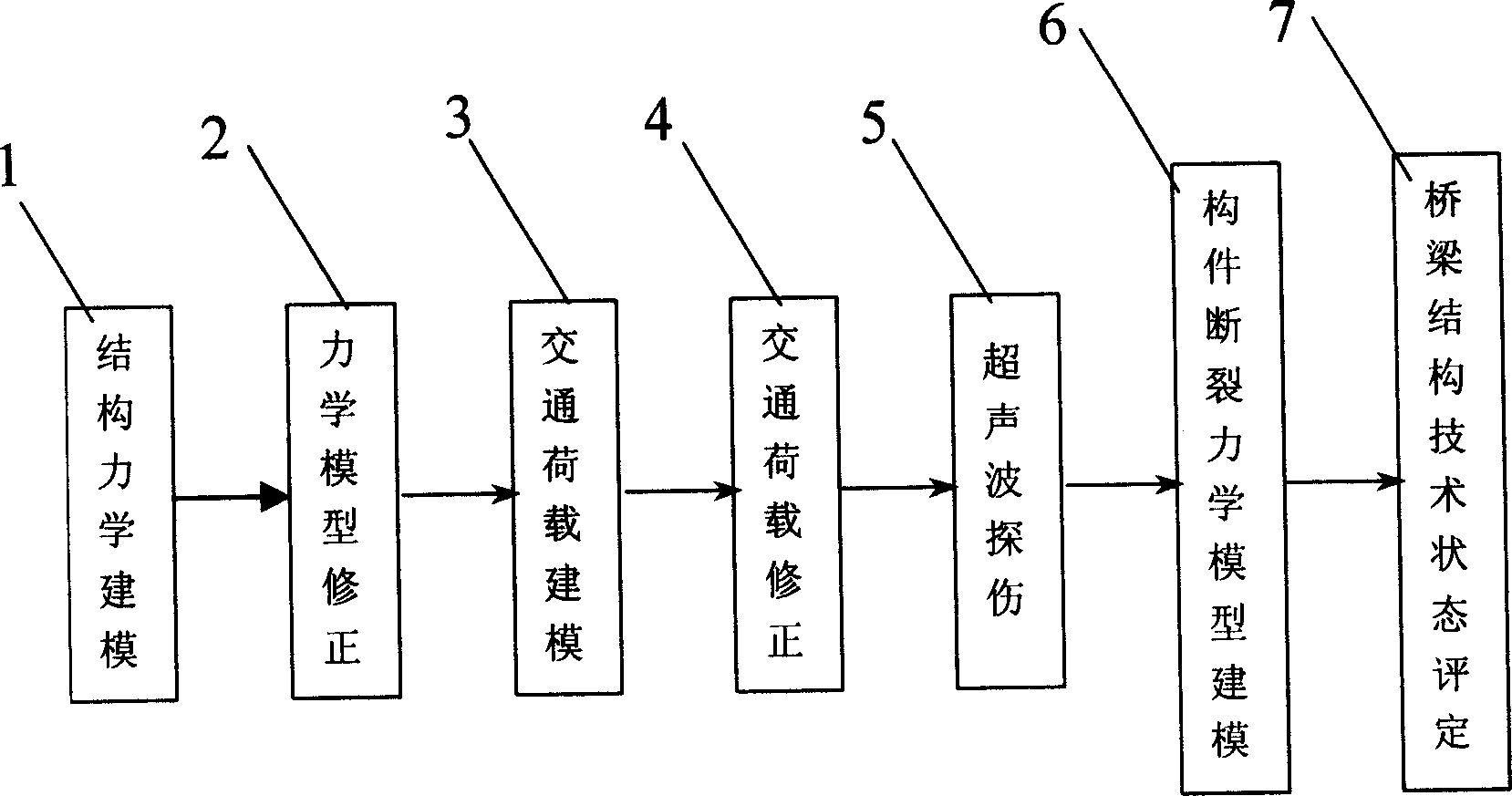

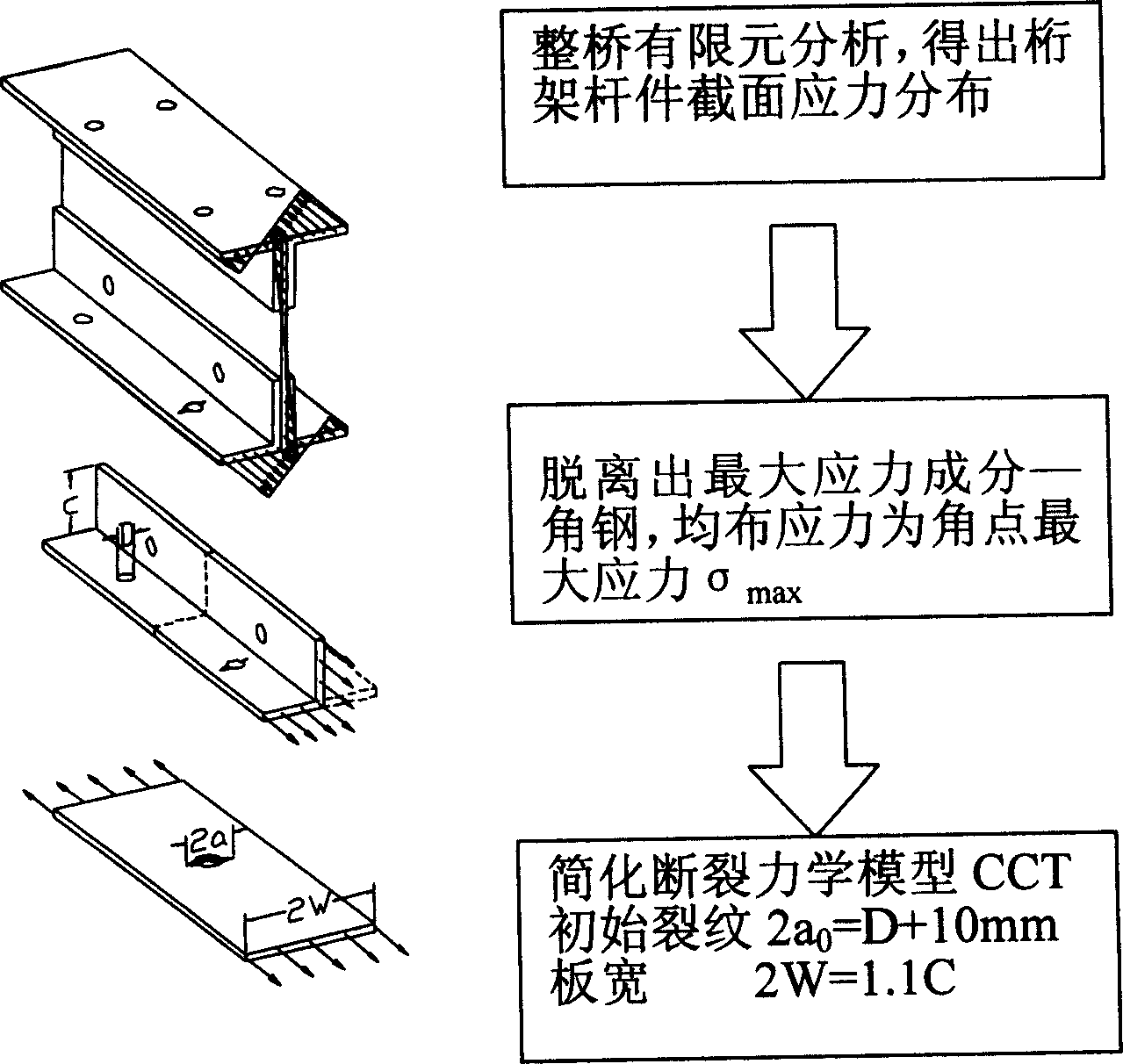

[0022] Such as figure 1 As shown, the fracture mechanics measurement method of the service life of a steel structure bridge in the present invention improves the accuracy of structural calculation by correcting the simulated data through the actual measurement data. The measurement method is divided into seven steps, which are respectively structural mechanics modeling 1. Mechanics model revision 2. Traffic load modeling 3. Traffic load correction 4. Ultrasonic flaw detection 5. Component fracture mechanics model modeling 6. Bridge structure technical state assessment 7.

[0023] The first step 1 is divided into four parts. The first is to investigate the bridge drawings and materials to determine all the structural details of the structure. The second is to simplify the structure. The third is to calculate the geometric characteristic parameters of the structure, and the fourth is to model.

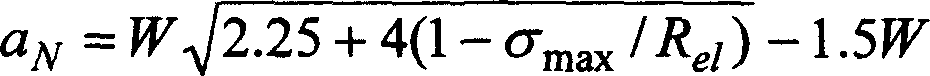

[0024] The second step 2 is divided into six parts. The first is to preliminarily de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com