Image sensing module

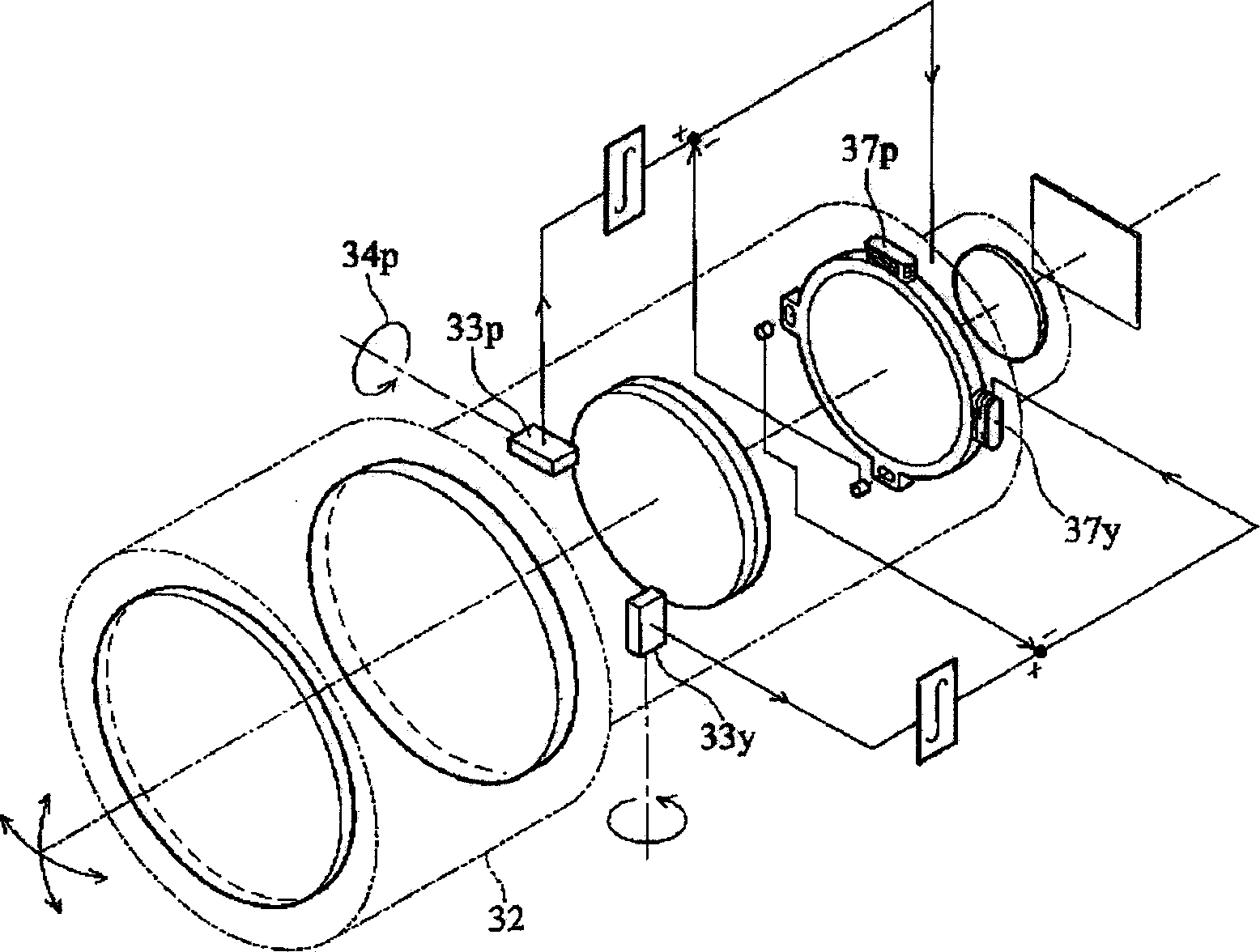

An image sensing and magnet technology, applied in optical components, optics, instruments, etc., can solve the problems of increased camera volume, heavy weight and bulky CCD components, etc., and achieve the effect of improving sensitivity and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

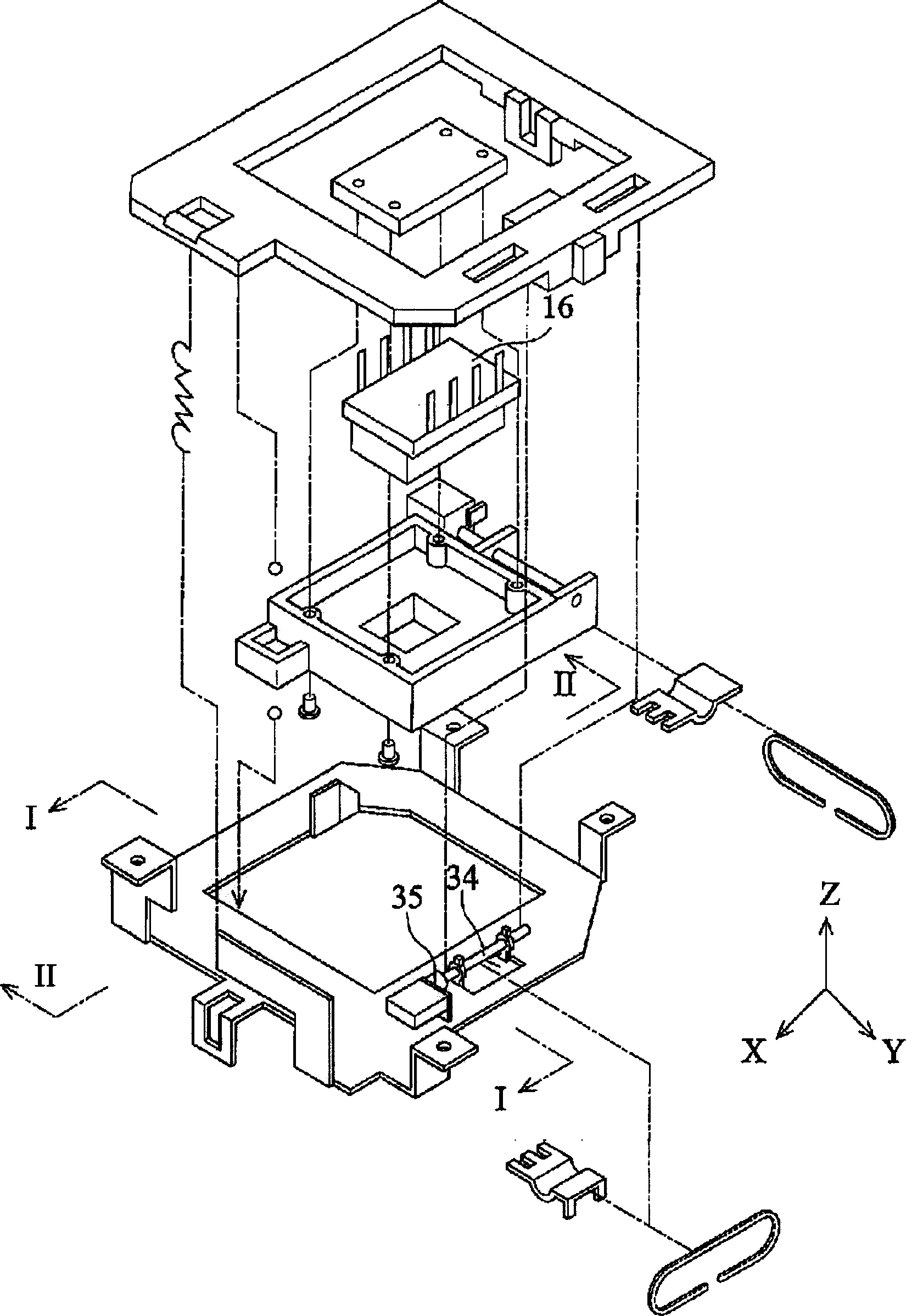

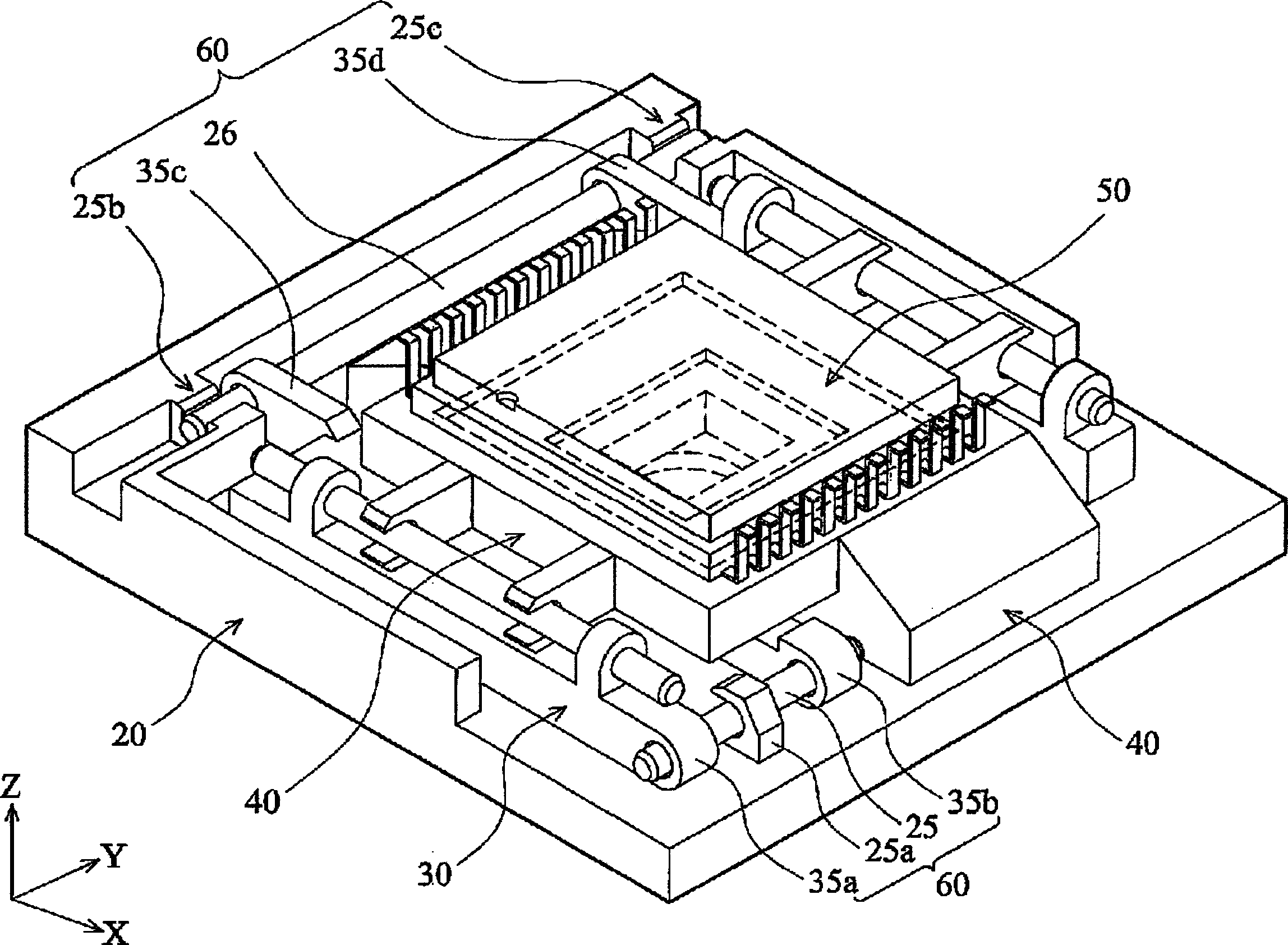

[0029] Before the present invention is described in detail, it should be noted that the relative position terms used in the following descriptions, such as "first direction X", "second direction Y", and "third direction Z" are based on the The marked coordinate direction is a reference, and the "first direction X", the "second direction Y" and the "third direction Z" are perpendicular to each other.

[0030] image 3 It is the image sensing module of the preferred embodiment of the present invention, which can be applied in the camera device to suppress or correct the image blur caused by the operator vibrating the camera. This preferred embodiment includes a fixed seat 20, and this fixed seat 20 has a hollow portion 29 (label reference Figure 4 ), and a bearing seat 30 is set in the hollow part 29; a movable plate 40 separated therein is provided in the bearing seat 30, wherein an image sensing unit 50, such as a CCD, is arranged on the movable plate 40. Wherein, the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com