Chemical etch assisted spark machining head

A technology of chemical etching and processing heads, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of not very convenient, waste of electrolyte, etc., to reduce the risk of sputtering and maximize the flexibility of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention stems from the general inventive idea of providing a chemically etch-assisted EDM head capable of three-dimensional movement that can machine large glass sheets with ease, accuracy, and at speeds compatible with industrial-scale production. Furthermore, in a preferred variant of the invention, the processing head is provided with means for supplying and discharging electrolyte, which allows the amount of electrolyte used to be reduced and avoids any risk of electrolyte sputtering.

[0025] The invention will now be described with reference to the machining of holes or cavities in glass sheets. Of course, the invention is not limited to this material, and the invention can be applied to drill holes in any type of non-conductive material such as plastic material, ceramic or semiconductor material.

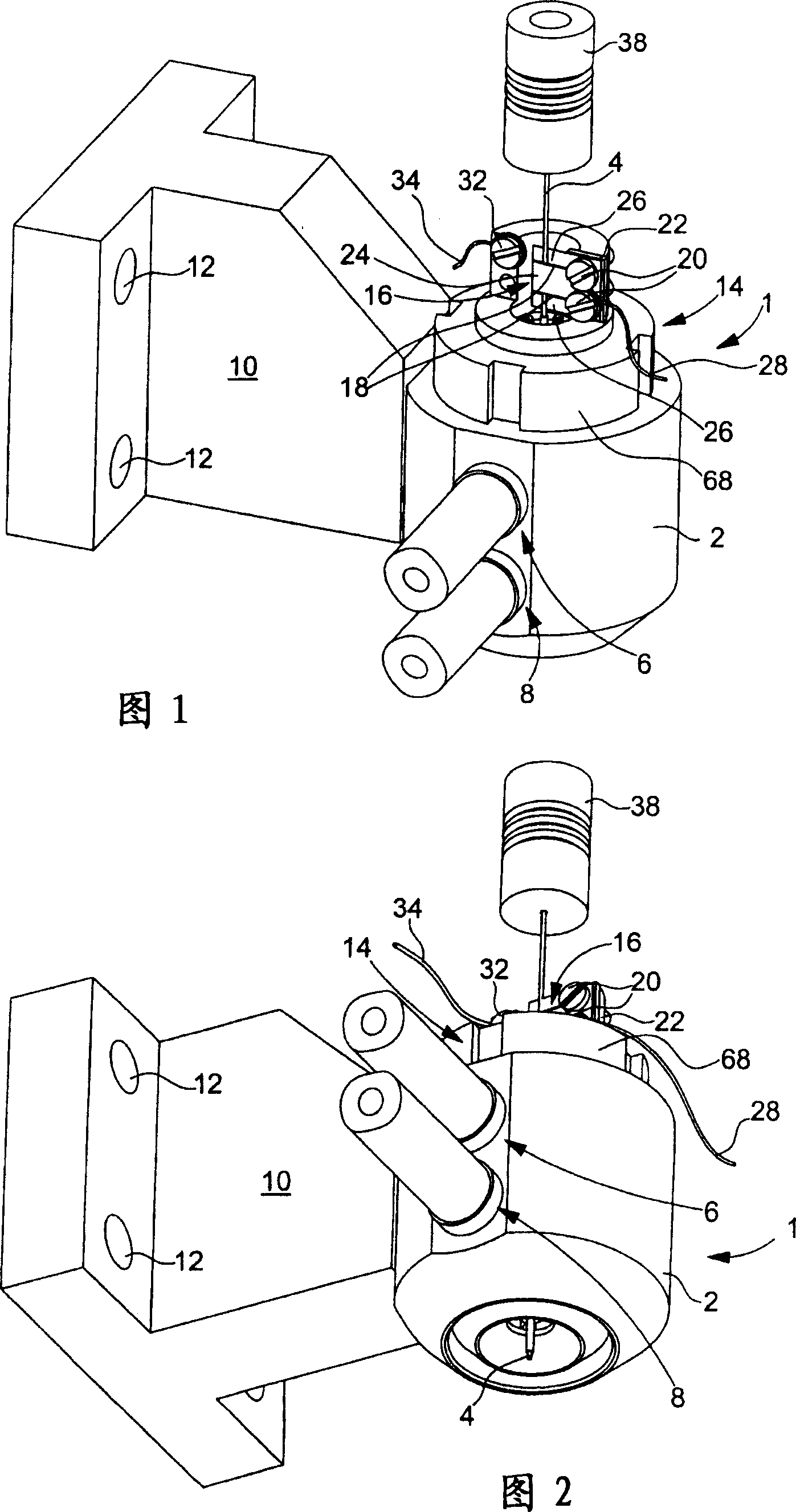

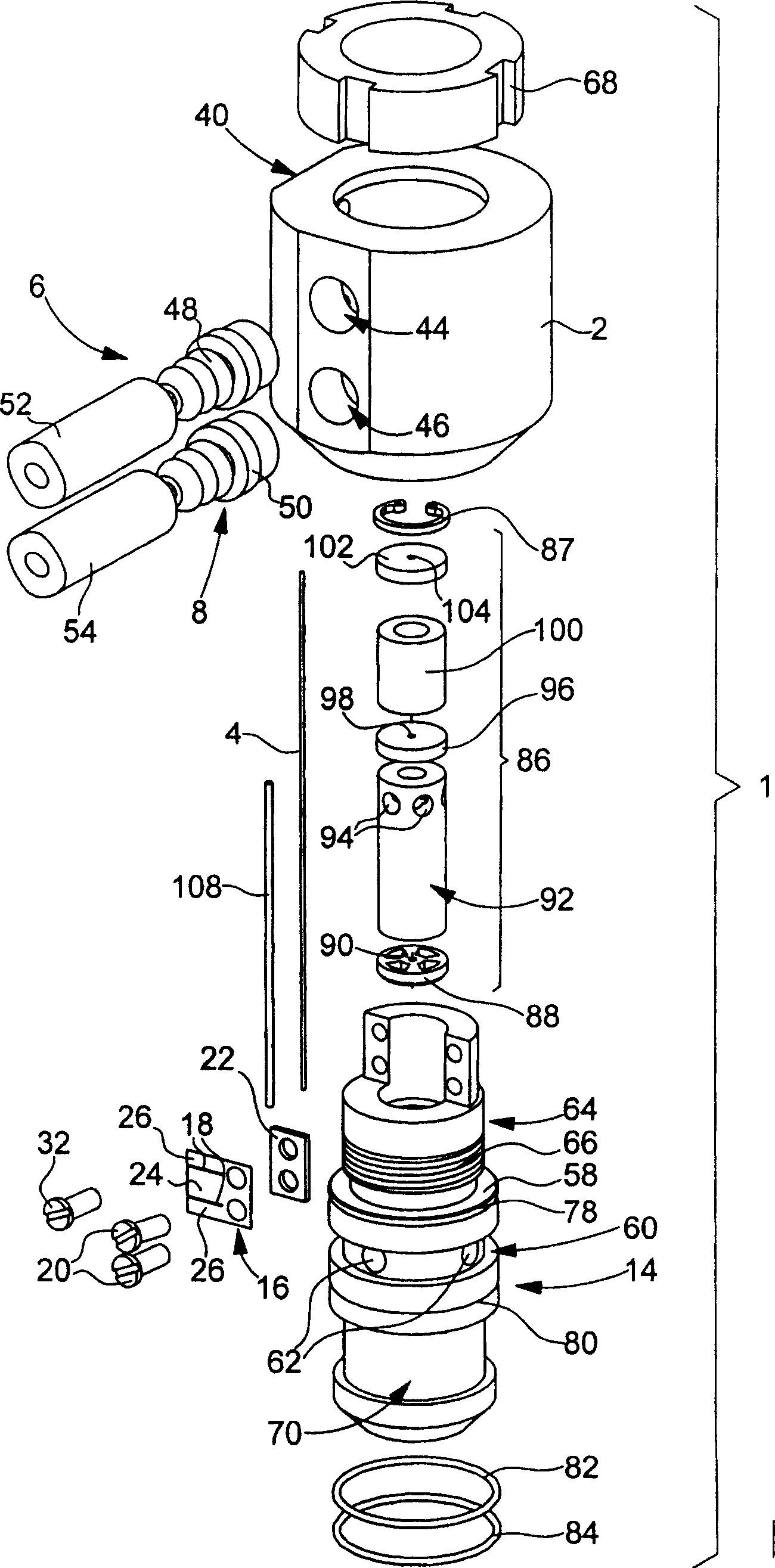

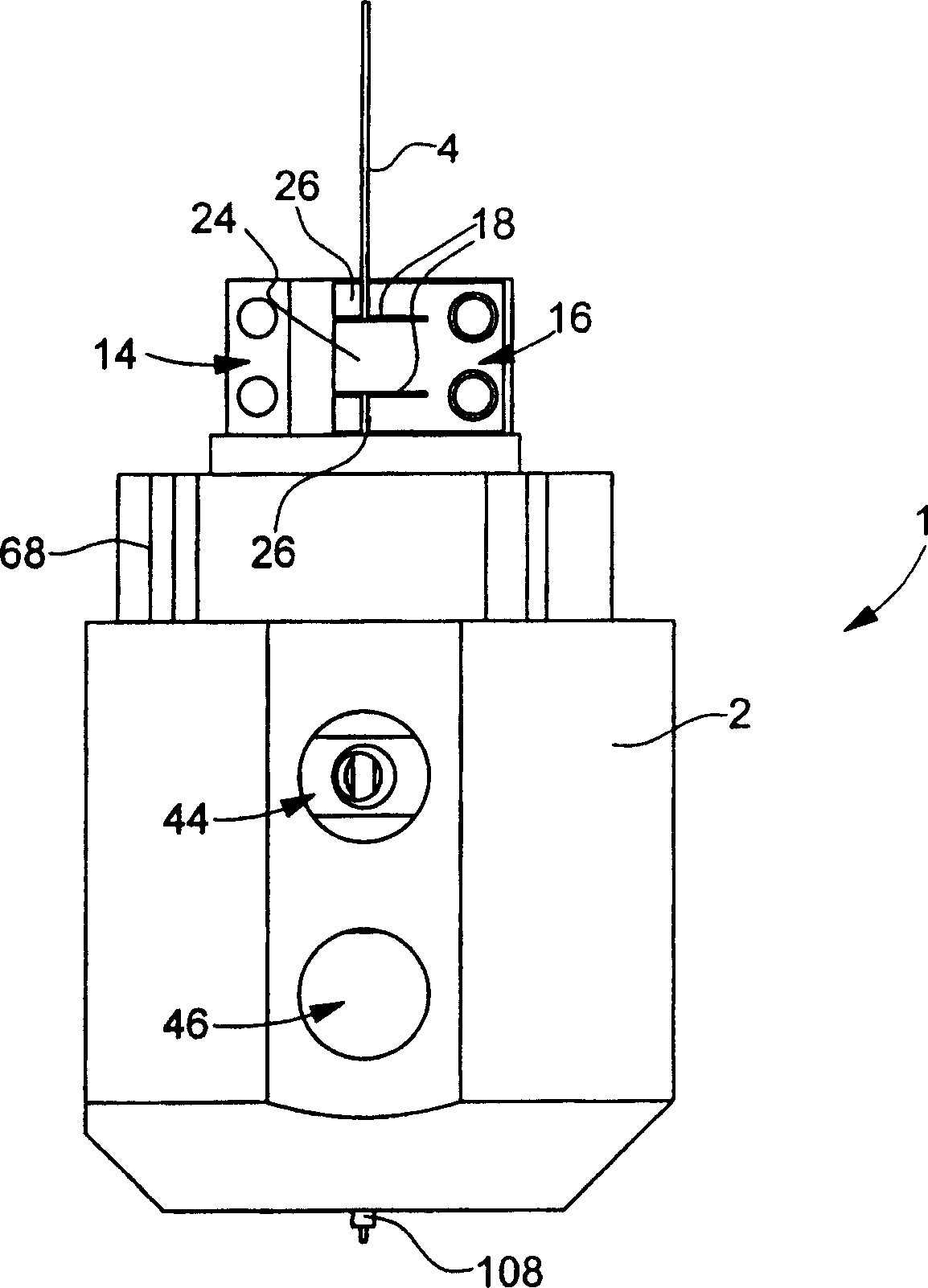

[0026] Figures 1 and 2 attached hereto show a machining head according to the invention, generally designated by the general reference numeral 1 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap