Full-closed automatic tobacco leaf on-line grade-determining, collecting and conveying line

A conveyor line, fully enclosed technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve problems such as difficulties and disadvantages, achieve fair settlement results, and prevent cheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

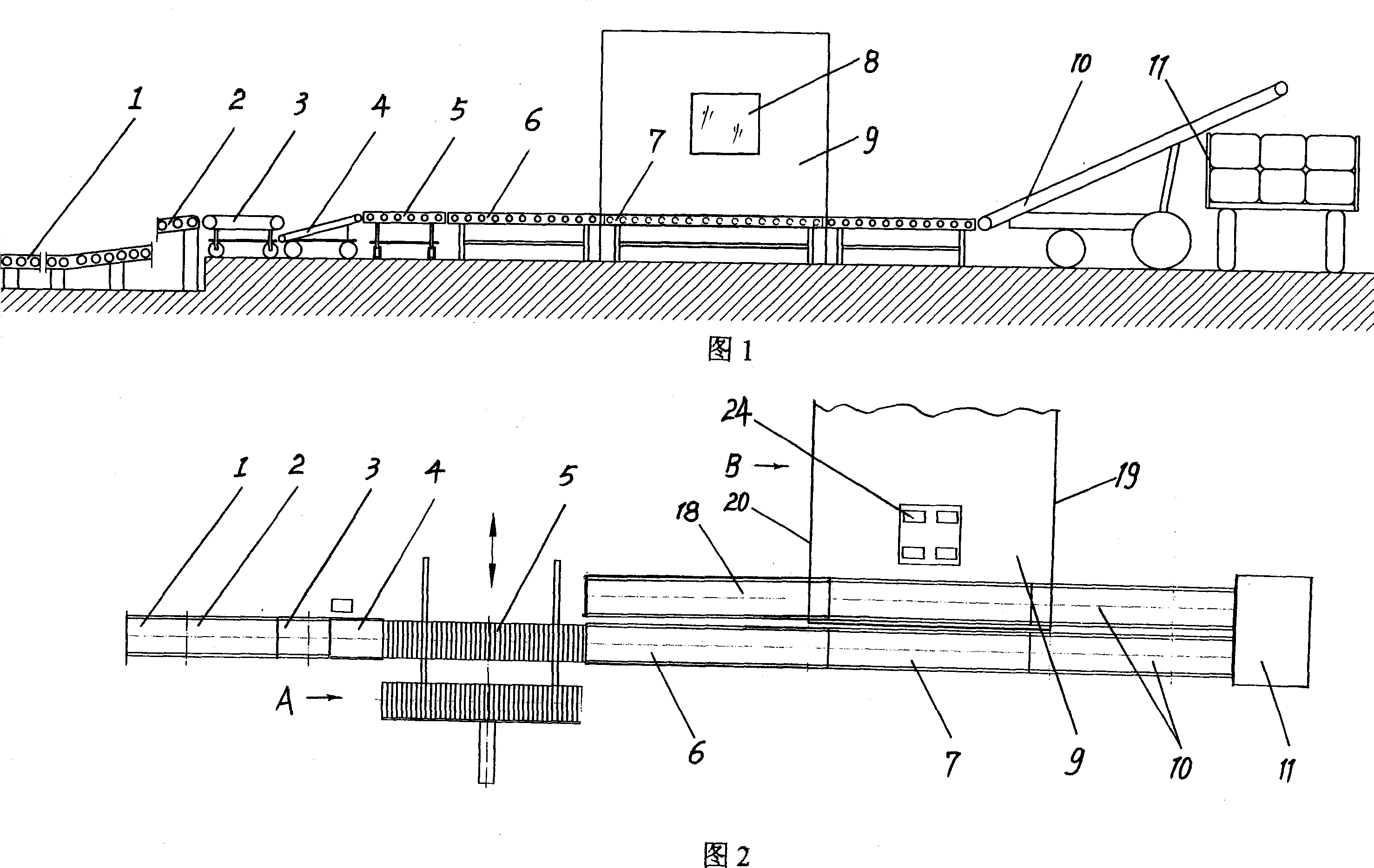

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

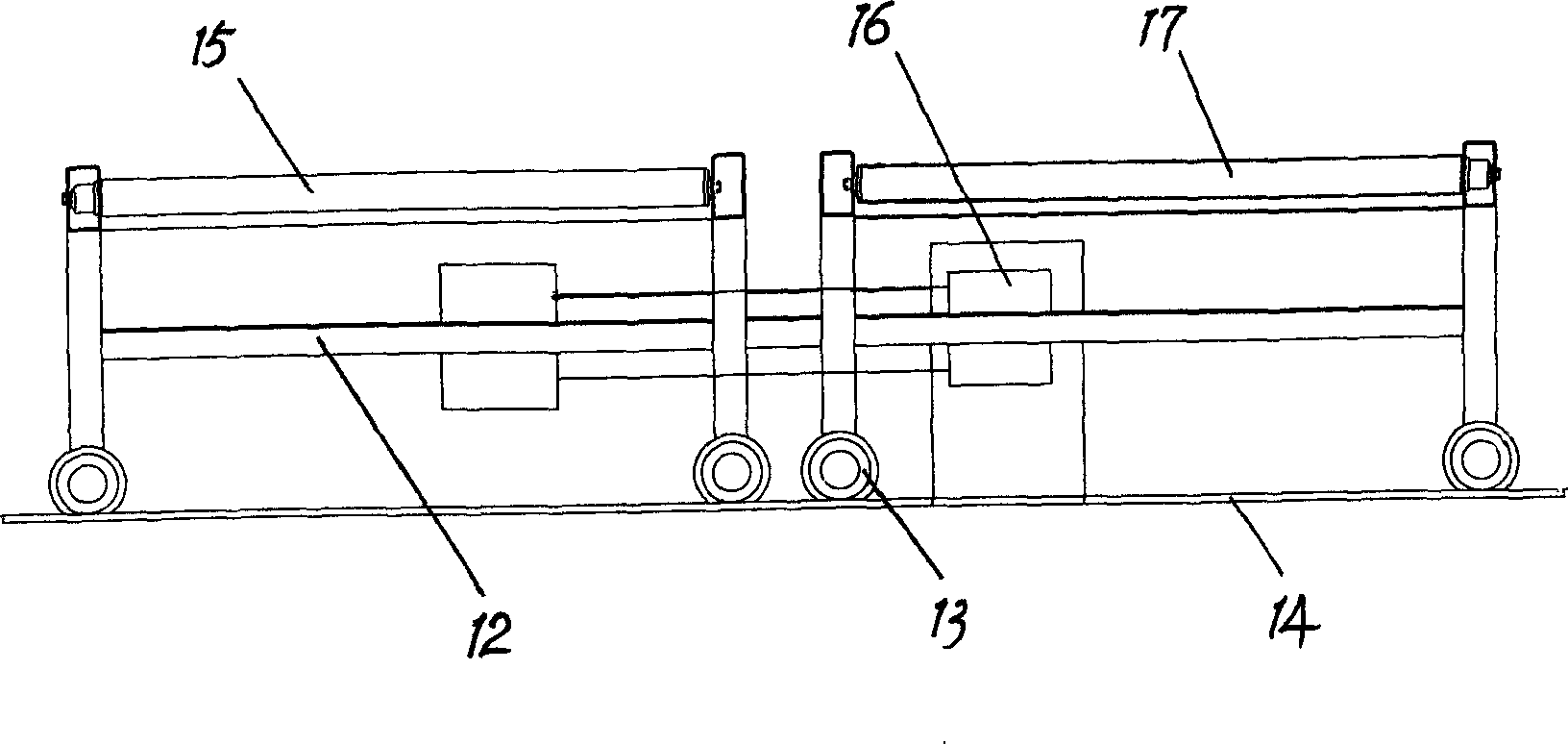

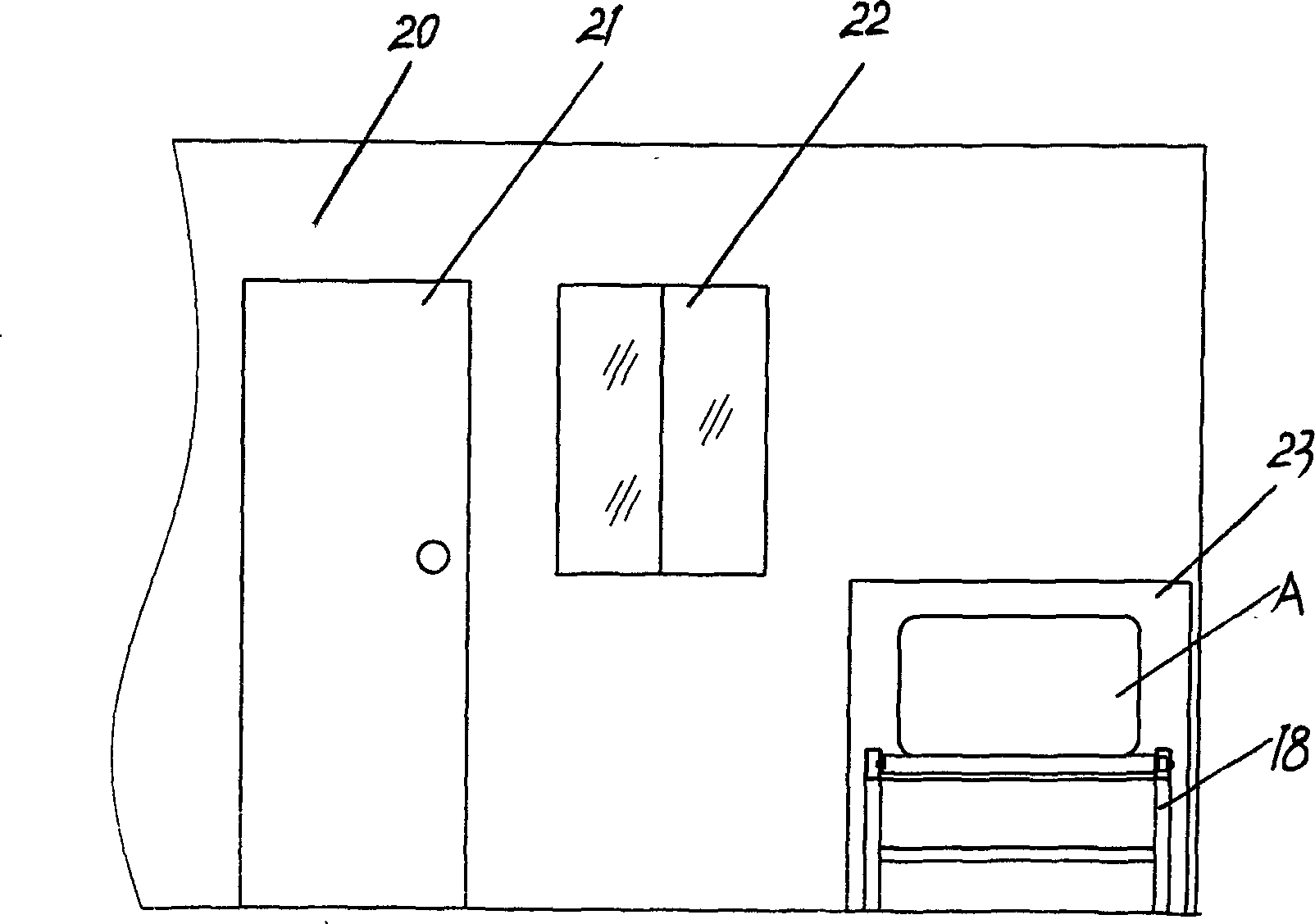

[0026] The vertical conveyor 1 is installed underground, and its conveying surface is kept parallel to the ground. One end of the slope conveyor 2 is connected to the conveyor 1, and the other end is connected to the mobile dynamic conveying scale 3, which is used to convey the cigarette packs from the ground to the mobile dynamic conveyor. Weighing and measuring are carried out on the conveying scale 3, and 4 is a transition conveyor. The end of the transition conveyor connected to the mobile dynamic conveying scale 3 is lower than the working table of the conveying scale 3. When the cigarette packs are weighed, they enter the transition conveyor 4 When going up, the tail end of the cigarette pack is automatically tilted, so as not to affect the weighing weight of the next cigarette pack, and the measurement accuracy is improved. The bottom of the frame 12 of the linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com