Aligning-positioning mechanism and aligning-positioning method

一种定位机构、定位构件的技术,应用在定位装置、金属加工机械零件、夹固等方向,能够解决工作周期长、调整工作困难等问题,达到容易调整的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

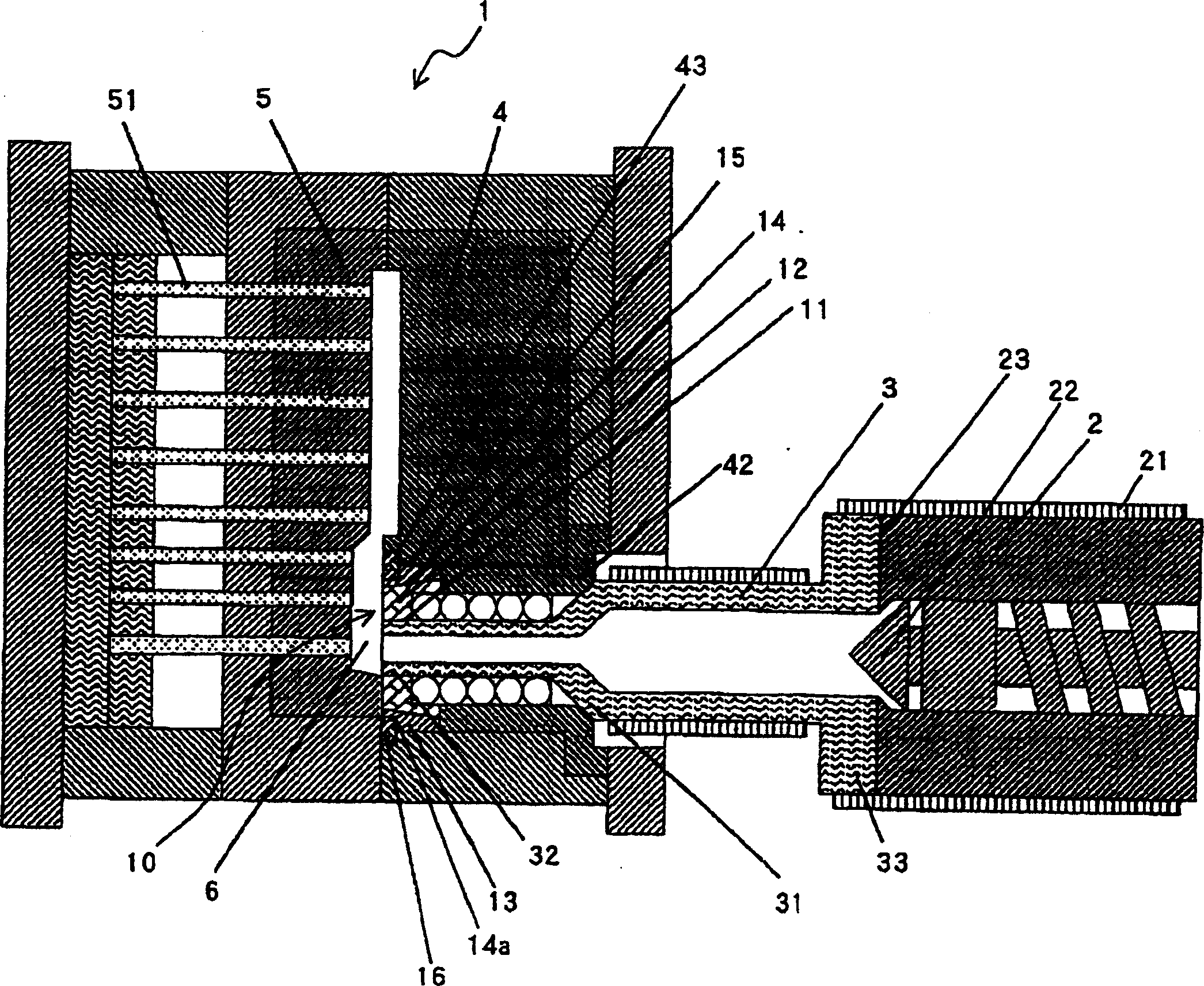

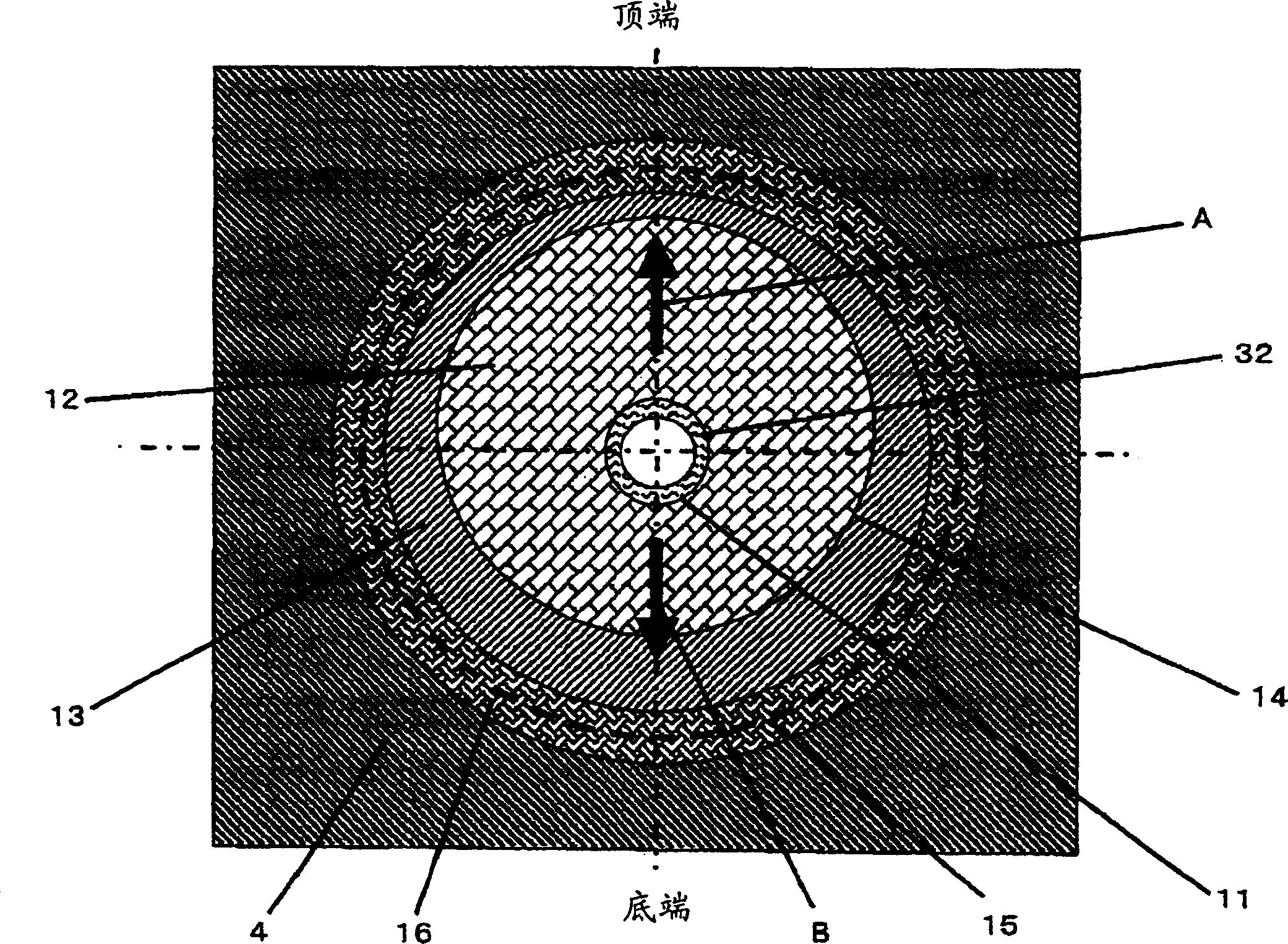

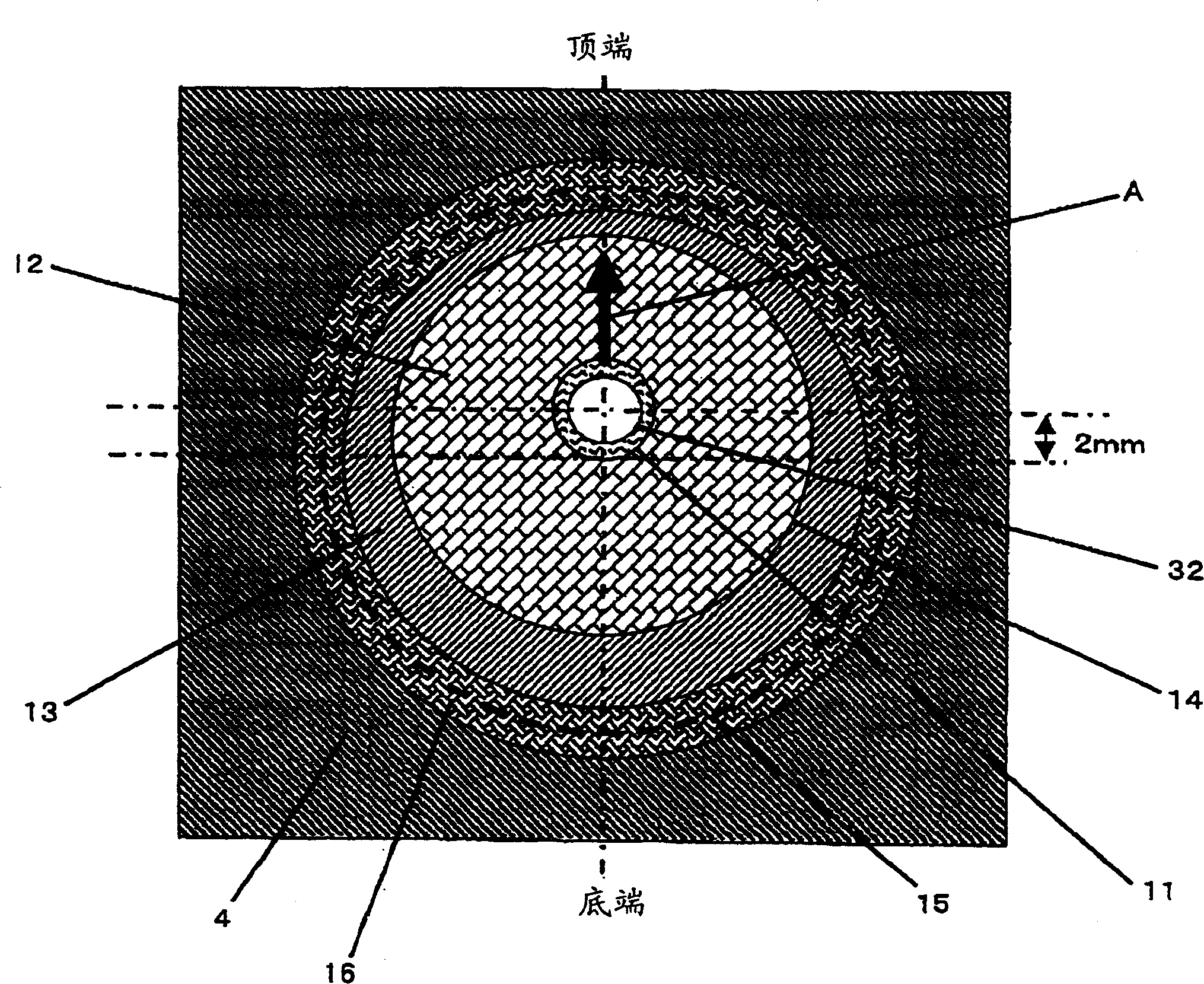

[0034] Embodiments of the present invention are described below with reference to the drawings.

[0035] figure 1 To illustrate a side sectional view of the configuration of a metal injection molding machine and a stationary die, one embodiment of the present invention is applied to this configuration.

[0036] [Metal Injection Molding Machine]

[0037] The metal injection molding machine includes: a heating cylinder 2 having a heater 21 disposed on its outer circumference; an extended nozzle 3 mounted on a front end portion 23 of the cylinder so that it can be inserted into a die; The screw rod 22 inside the barrel 2. The extension nozzle 3 includes: a front end portion 32 fitted in the inner disc hole 11 of the inner disc 12 described later; a mounting end 33 mounted adjacent to the cartridge front end portion 23; and a mounting end 33 formed between the front end portion 32 and the mounting end 33 Tapered portion 31 .

[0038] [die]

[0039] The die 1 includes a fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com