Grinding machine for rubbing

A kind of grinding tool and grinding layer technology, which is applied in the direction of abrasive materials, manufacturing tools, and wheels of working parts with flexible functions, so as to improve the grinding responsiveness and eliminate the uneven grinding effect

Inactive Publication Date: 2006-12-06

KURE GRINDING WHEEL

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] However, there is a problem that sometimes unacceptable grinding unevenness can be observed on the surface to be ground of the workpiece ground with the existing grinding wheel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0087] Embodiment one: the rubber sponge material of INOAC company C-4205

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

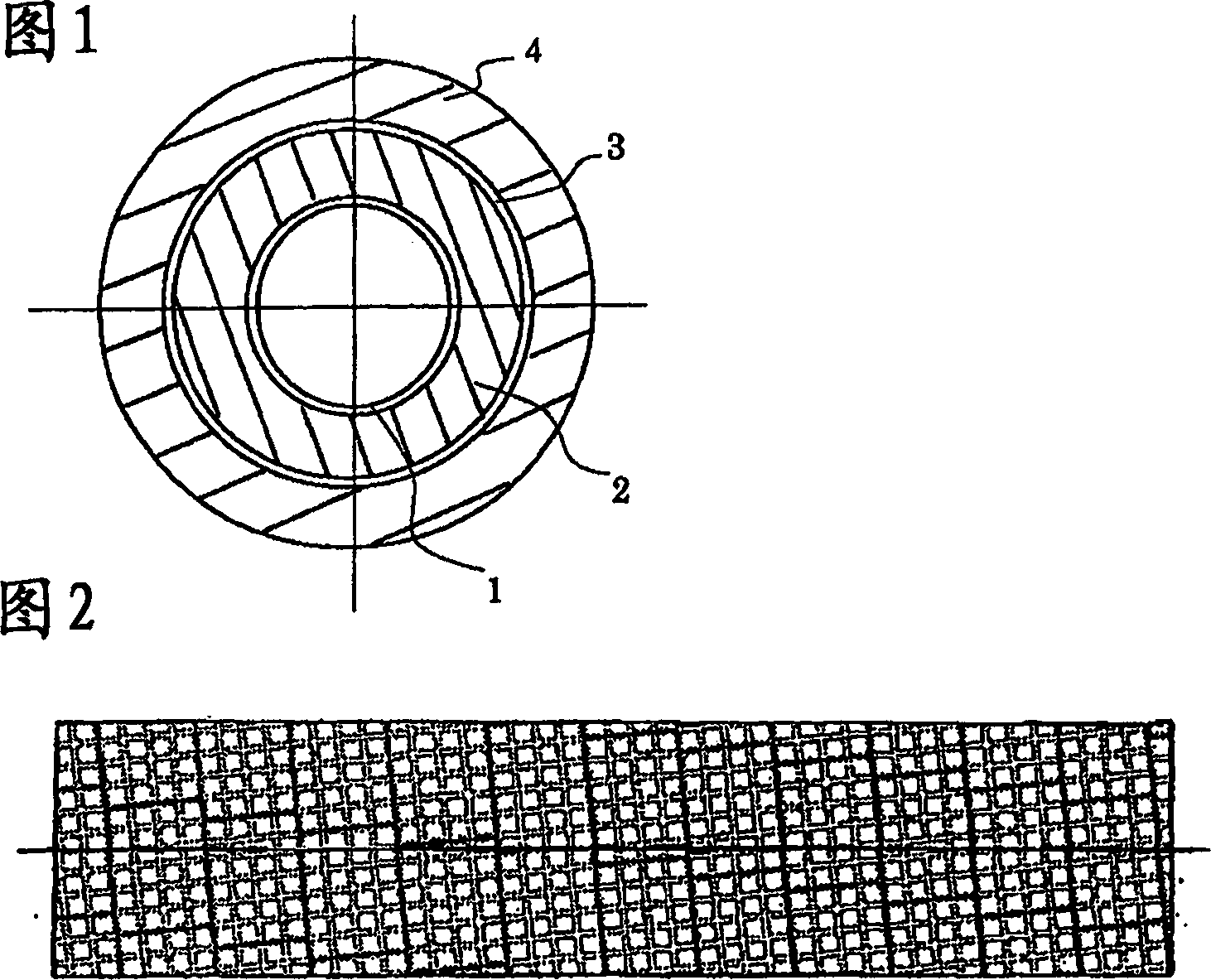

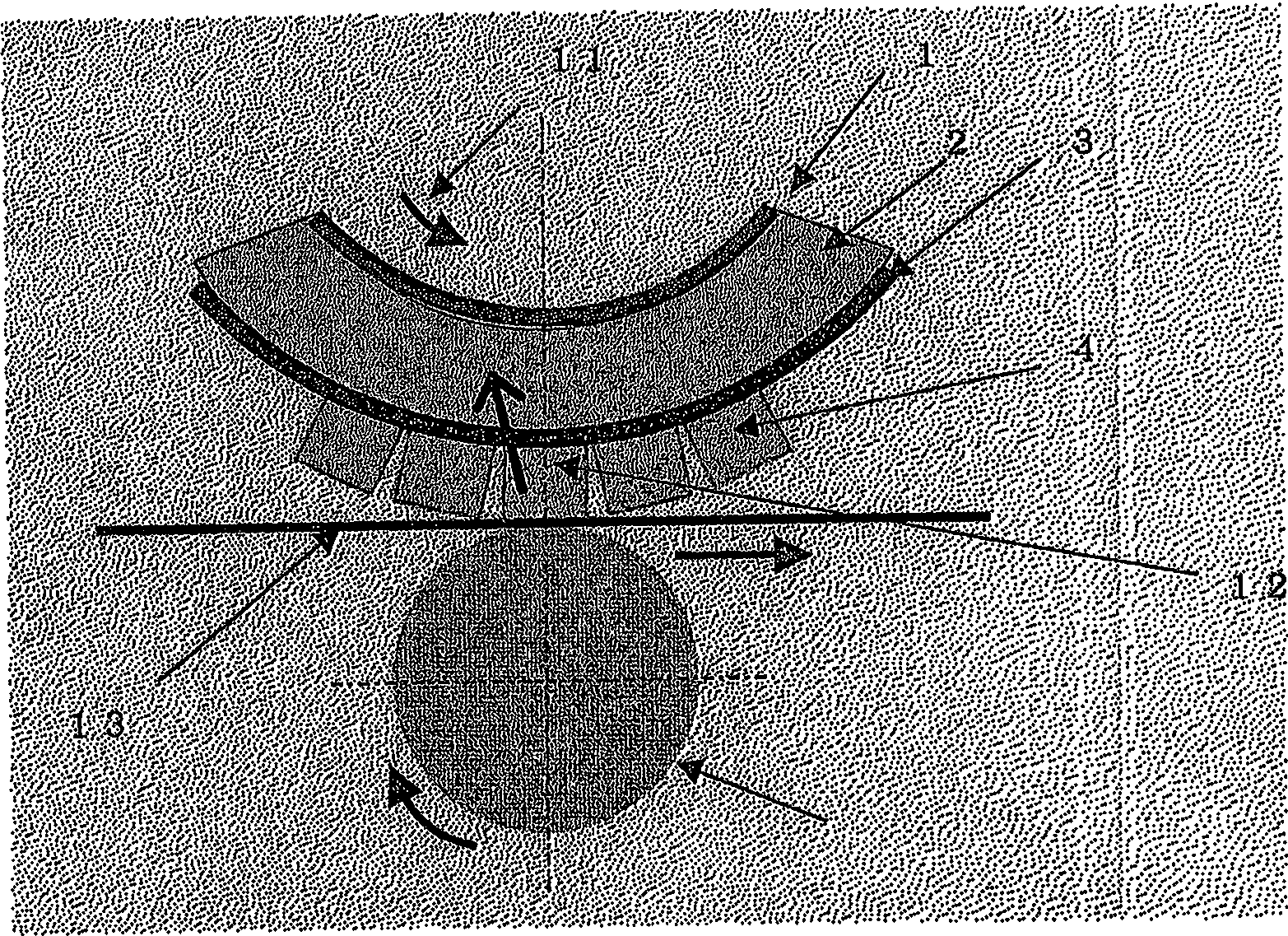

The invention provides a grinding device for plate-like clipped material, which is characterized by even grinding and good pressure responsibility. The cylinder chip material (1) is equipped with porous elastic material (2), the outer of which is provided with grinding layer (4), and said porous elastic material is rubber sponge. The hardness of rubber sponge is 5-40 when test by rubber hardness gage C graduation, and the best elastic rate is 50-90%, while the best 25% compress loading value regulated by JIS K 6767 is 0.010- 0.200 Mpa.

Description

technical field [0001] The present invention relates to a grinding tool for grinding a plate-shaped workpiece, and more particularly relates to a grinding tool for grinding a metal plate or a non-metal plate, especially a printed circuit board. Background technique [0002] Conventionally, as a grinding tool for grinding a plate-shaped workpiece represented by a printed wiring board, there are known grinding tools disclosed in JP-A-2001-315054 and JP-A-2004-50400. [0003] Abrasives used for grinding plate-shaped workpieces, one example of the structure, as shown in Figure 1, is provided with a porous elastic body (2) on a cylindrical core material (1), and the porous elastic body A grinding layer (4) is provided on the outer periphery of the body (2) between the reinforcement layer (3). The material of the cylindrical member is, for example, a so-called phenolic tube made of paper tube impregnated with phenolic resin and reinforced, which is light, rigid and excellent, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24D13/12

CPCB24D13/12

Inventor 宫本幸一相川和也

Owner KURE GRINDING WHEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com