High temperature sclerometer capable of conducting continuous temperature changing multi-point testing

A multi-point test and hardness tester technology, applied in the direction of testing material hardness, etc., can solve the problems of limited moving distance of samples, complicated and time-consuming testing process, inability to continuously test multi-point hardness values, etc., to increase the number of hardness values measured. , The effect of good promotion and use value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

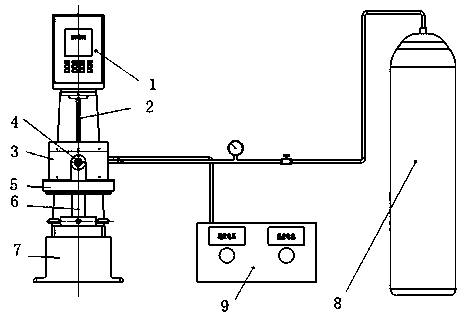

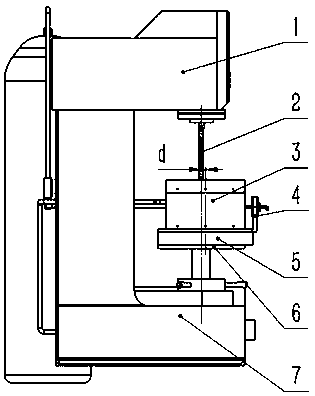

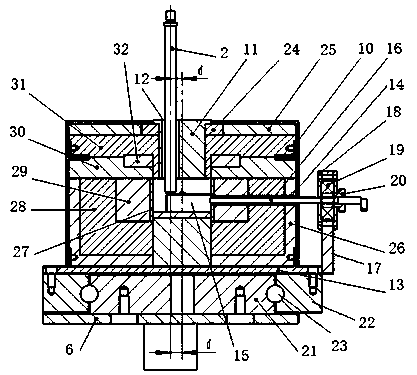

Embodiment 1

[0033] In this embodiment, a variable temperature hardness tester arranged in an eccentric furnace is used, and a heating furnace induction heating control structure and heating furnace atmosphere protection equipment are used to adjust the test atmosphere and temperature of the sample. The distance between the dots of the sample that is often carried out is required to be 2mm, so the eccentricity d1 of the center line of the heating furnace and the hardness tester in this example is 10mm, and the effective moving stroke L of the sample is 15mm. After equipment verification, one sample in this example can be used for 105 tests of hardness value determination. If it is calculated according to the experimental requirements of carrying out 10 tests for each test condition and taking the average value, the test conditions of 10 samples can be adjusted and changed without turning on the furnace, such as changing the temperature of 10 samples.

Embodiment 2

[0035] In this embodiment, a variable temperature hardness tester arranged in an eccentric furnace is adopted, the experimental temperature of the sample is adjusted by the induction heating control structure of the heating furnace, and the vacuum equipment of the heating furnace is used to protect the sample from oxidation. The distance between dots of samples that is often carried out is required to be 3 mm. In this embodiment, the eccentric distance d1 of the center line of the heating furnace and the hardness tester is 18 mm, and the effective moving stroke L of the sample is 30 mm. After the equipment test verification, the same sample in this implementation can be used for 180 times of hardness value determination tests. If it is calculated according to the experimental requirements of carrying out 10 tests for each test condition and taking the average value, the temperature of the sample can be adjusted and changed 18 times without turning on the furnace, and the variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com