Method and apparatus for filling liquids into foil bags with a spout

A technology of liquid and spout, which is used in the field of filling liquid into foil-lined bags with spouts and equipment, which can solve the problems of dirty and sticky bags, and achieve small head space, simple structure, and compactness mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

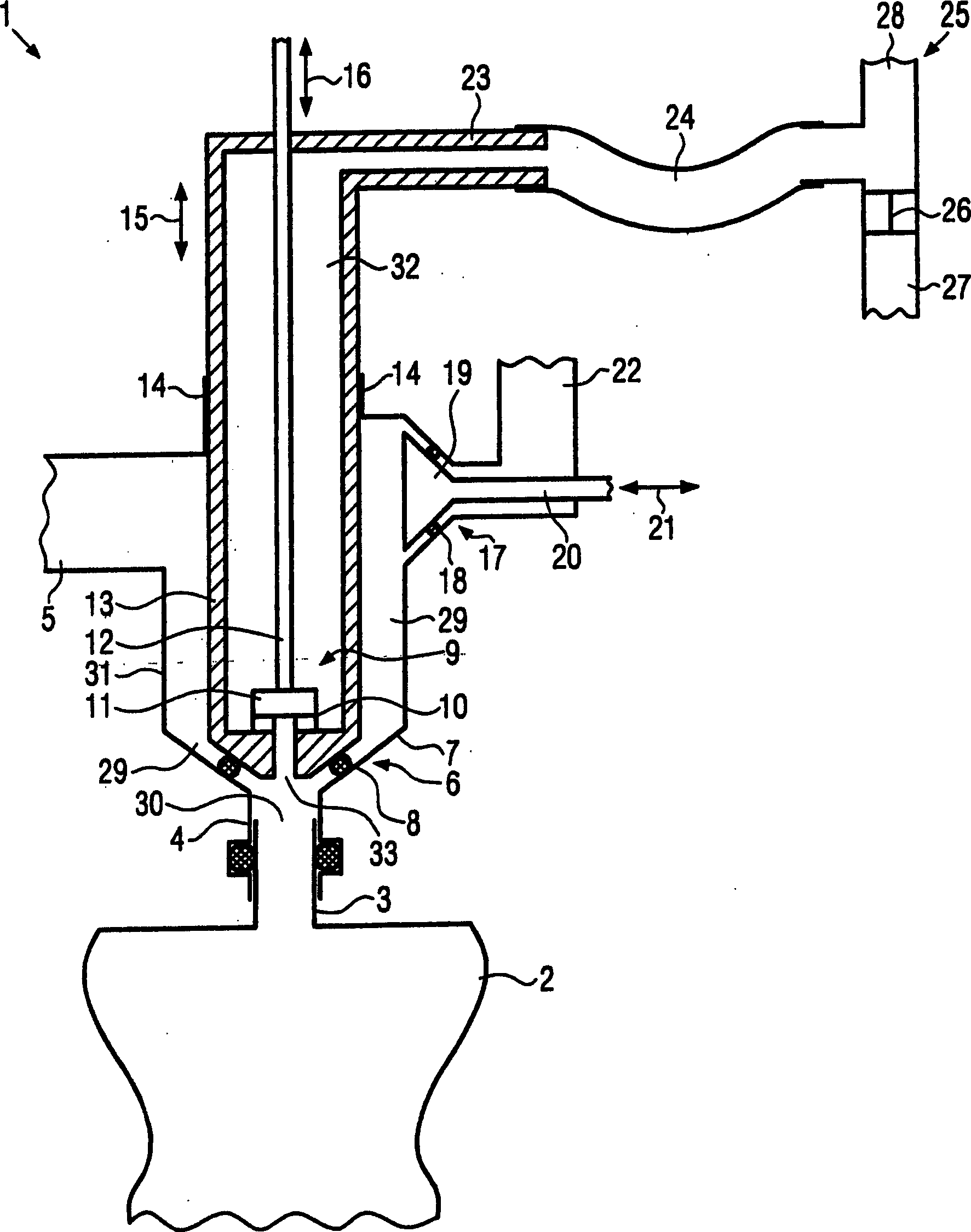

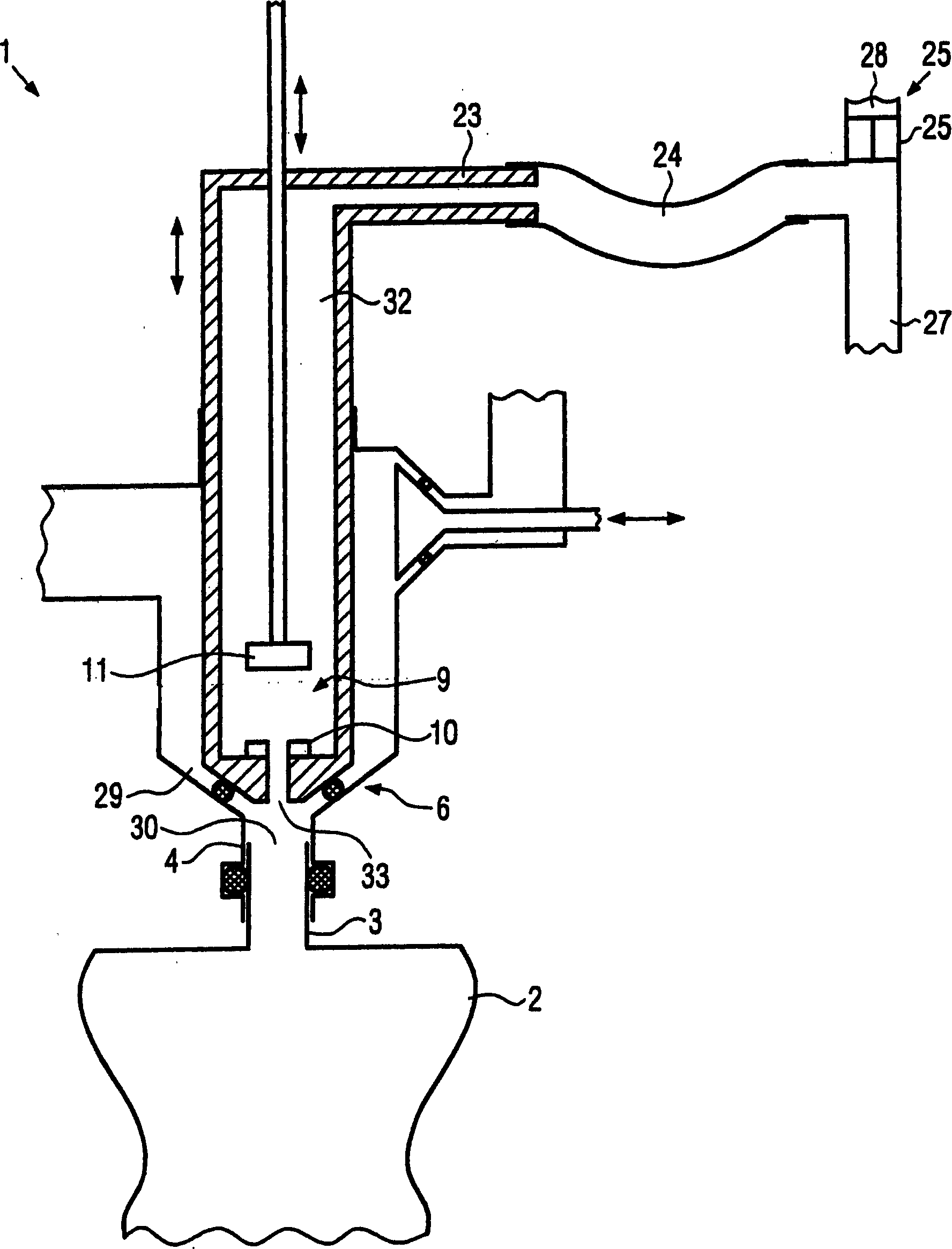

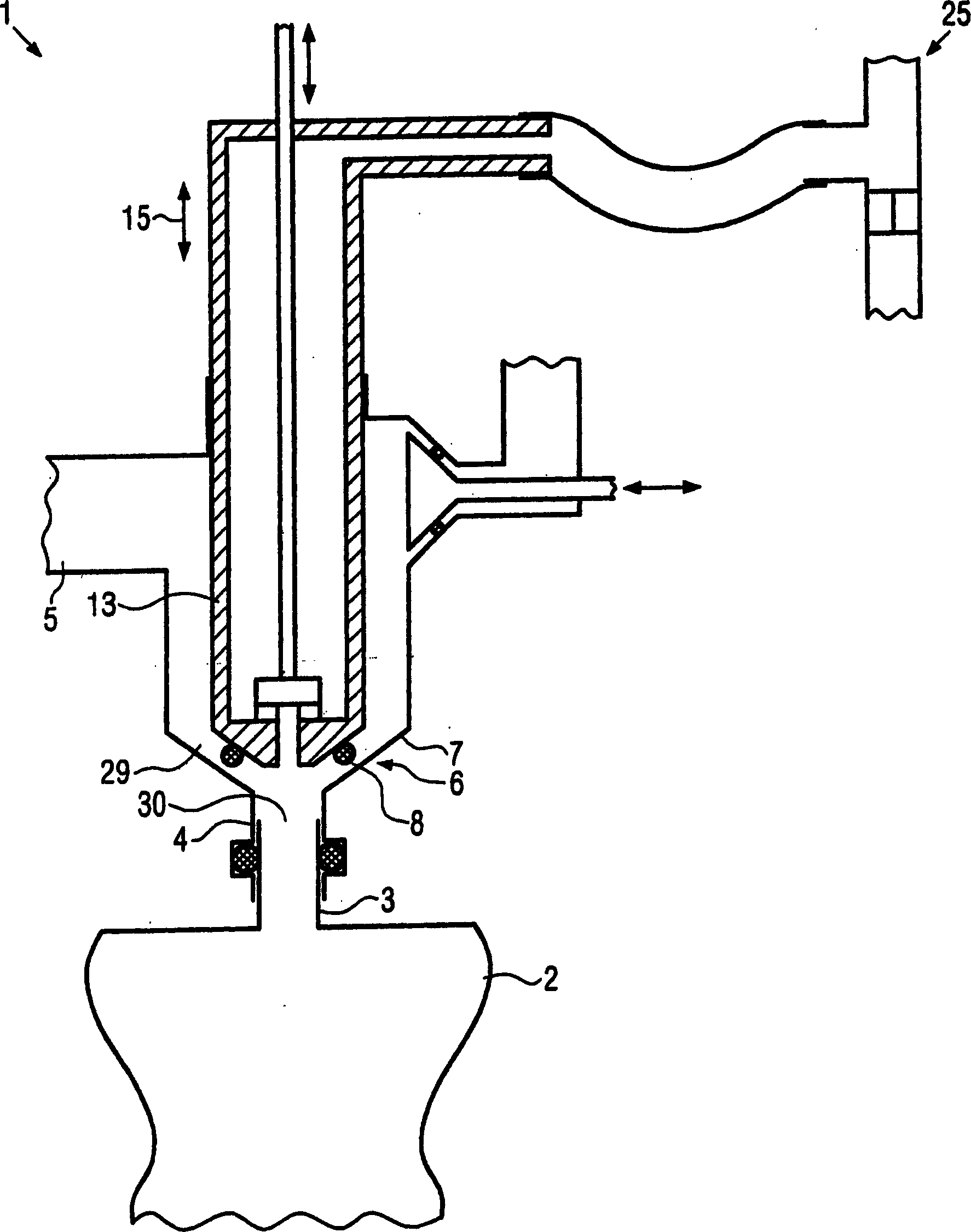

[0025] figure 1 A device 1 for filling foil-lined bags 2 with a spout 3 is shown. The spout 3 of the foil-lined bag 2 fits onto the fill hole 4 . Here, the spout 3 can be inserted or pulled into an opening (for example a small tube) from below.

[0026] The liquid supply line 5 is arranged on the side of the main pipe 31 . The main pipe 31 extends in a direction transverse to the liquid supply line 5 and is oriented vertically up to the filling hole 4 . The lower end of the main tube 31 has a tapered inner side 7 .

[0027] A filling valve 6 is arranged above the filling opening 4 . The filling valve 6 comprises an annular seal 8 which can be pressed against the conical inner side 7 . Here, the seal 8 is arranged on a movable piston 13 which is movable up and down in direction 15 . The seal 8 can also be arranged on or in the conical inner side.

[0028] figure 1 Piston 13 is shown in its lower position, with seal 8 resting on inner side 7 , thus representing closed fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com