Resonance device for vibration experiment

A technology of a resonator device and a vibrating table, which is applied in the field of resonator devices, can solve problems such as difficulty in breaking through, and achieve the effect of simple structure, obvious effect and improving high-frequency resonance point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

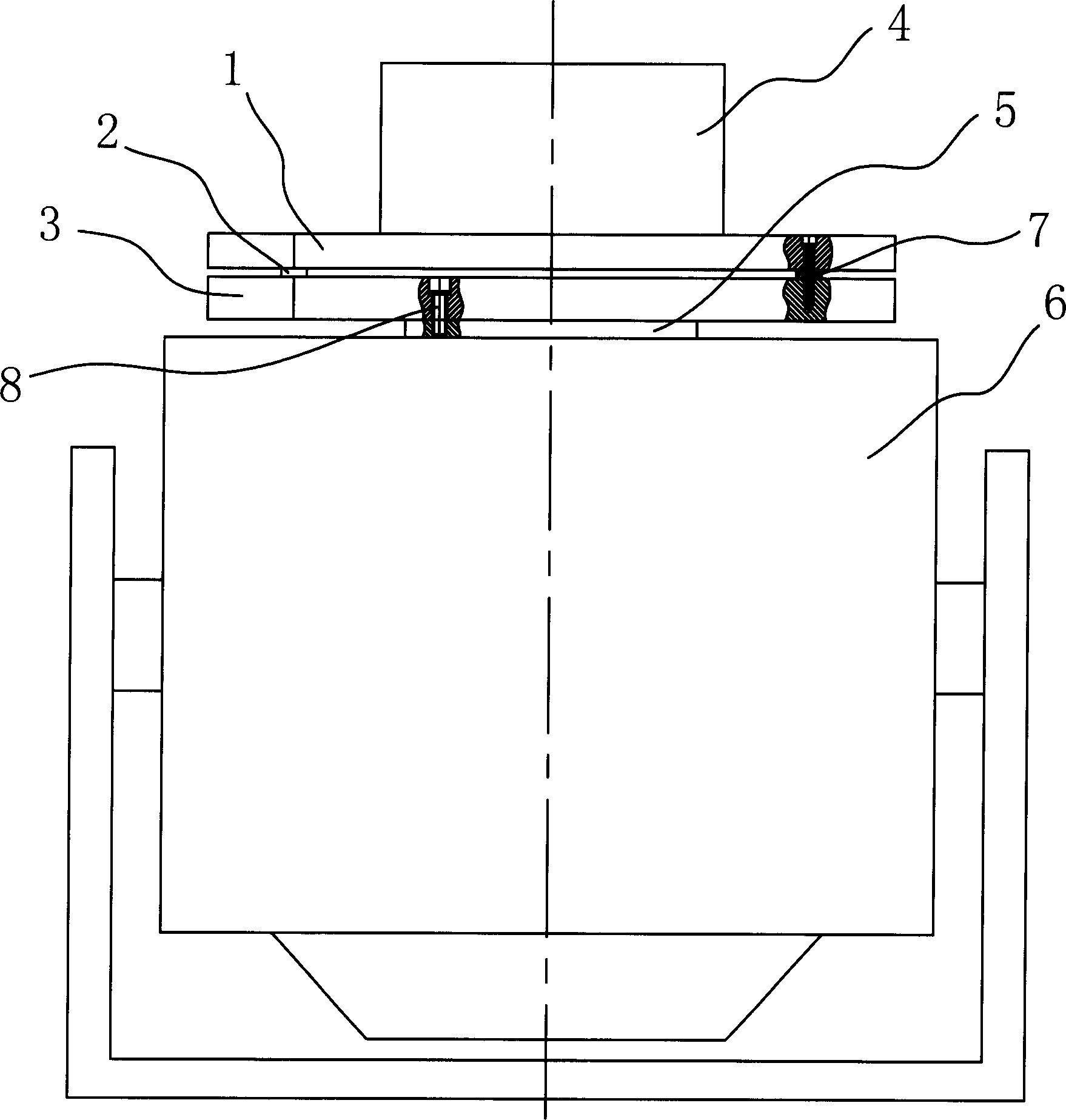

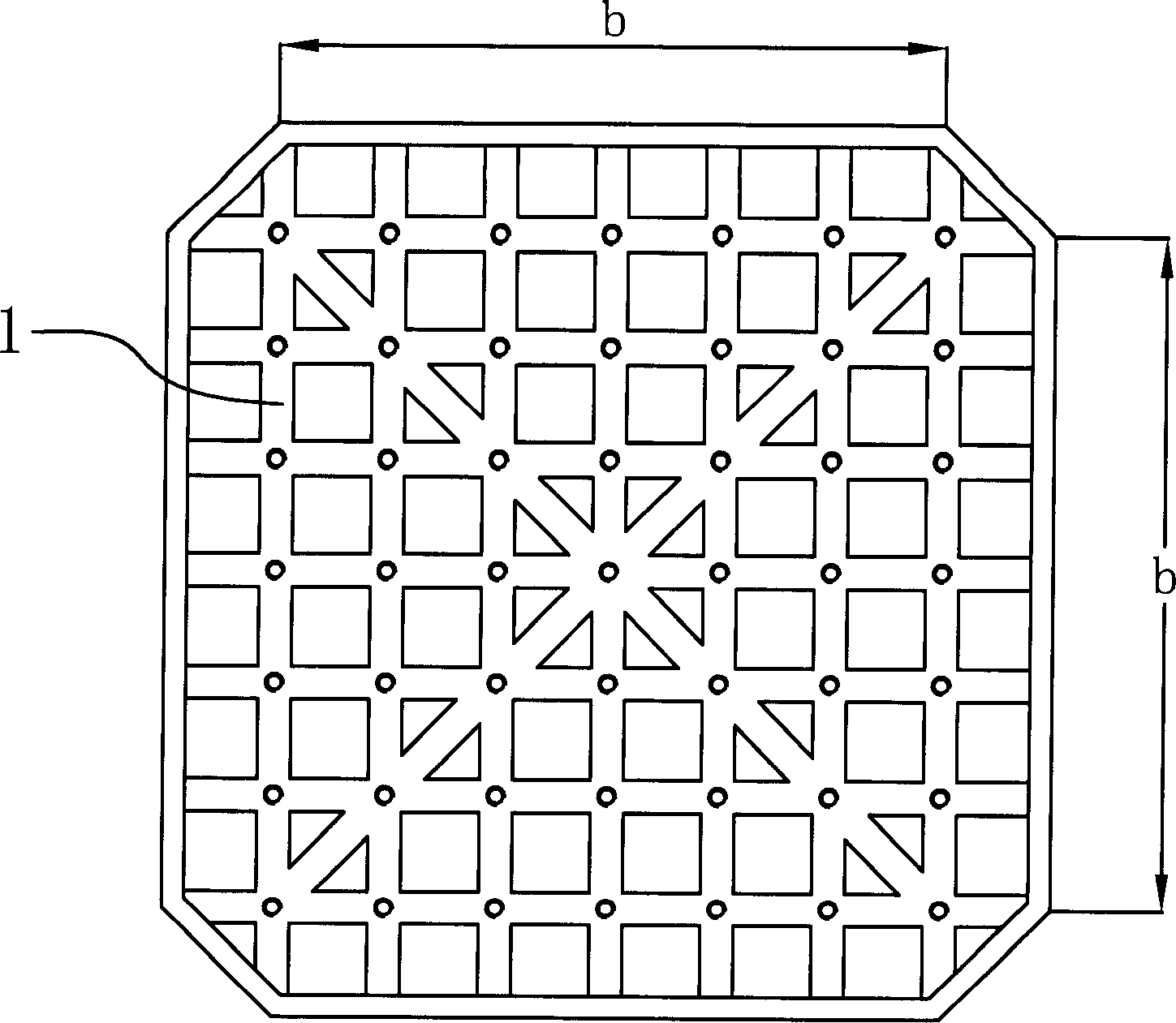

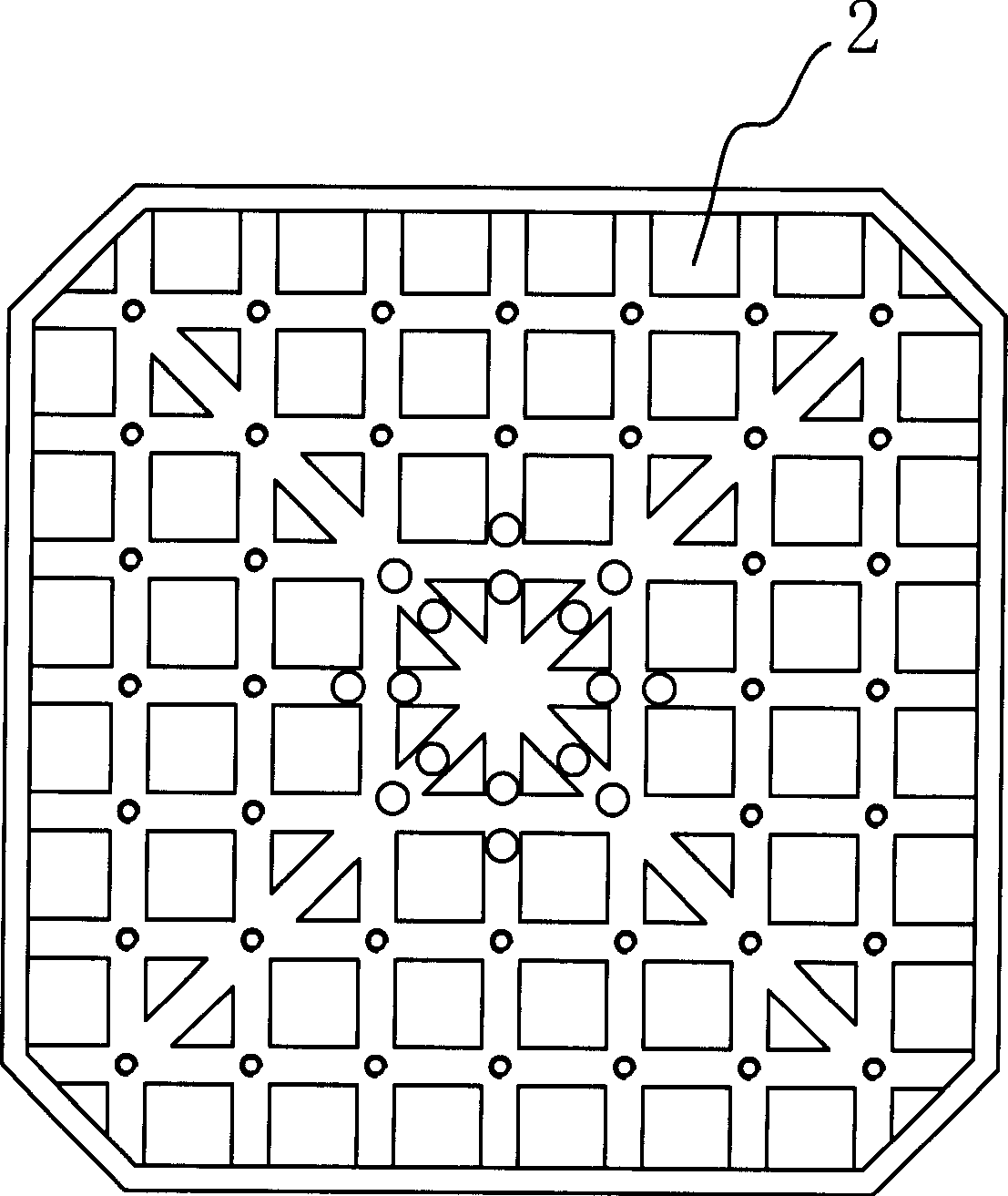

[0058] Example: see Figure 1 to Figure 4 As shown, a resonance device for vibration test is composed of an additional workbench 1, support pad 2 and coupling 3. The vibrating table used together is the DC-3000-36 electric vibrating table produced by our company. The first-order natural resonance frequency of the moving coil of the electric vibrating table is 2200Hz, and the highest frequency that can be achieved is about 3000Hz.

[0059] The additional workbench 1 is a rigid platform, the top surface of which is an additional platform for placing the test piece 4, the bottom surface of the platform is surrounded by support pads 2, and the middle part of the platform is suspended relative to the bottom plane of the support pad 2. The rigid platform adopts a square platform, and its first-order natural resonance frequency is calculated as follows:

[0060] Select Material: Aluminum

[0061] E-modulus of elasticity: 68Gpa

[0062] μ-Poisson's ratio: 0.35

[0063] t=50mm

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com