Vibration Fatigue Test Device and Installation Method for Axial Variable Stress Ratio of Metal Materials

A vibration fatigue, metal material technology, used in measuring devices, analyzing materials, using repetitive force/pulse force to test the strength of materials, etc. The effect of high test frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

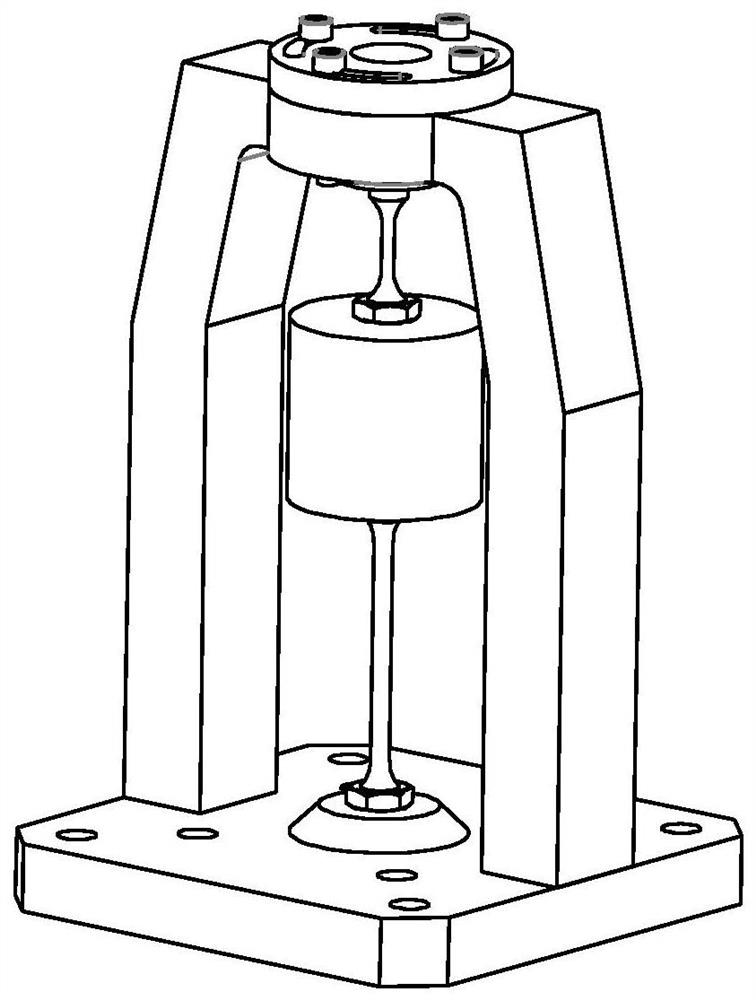

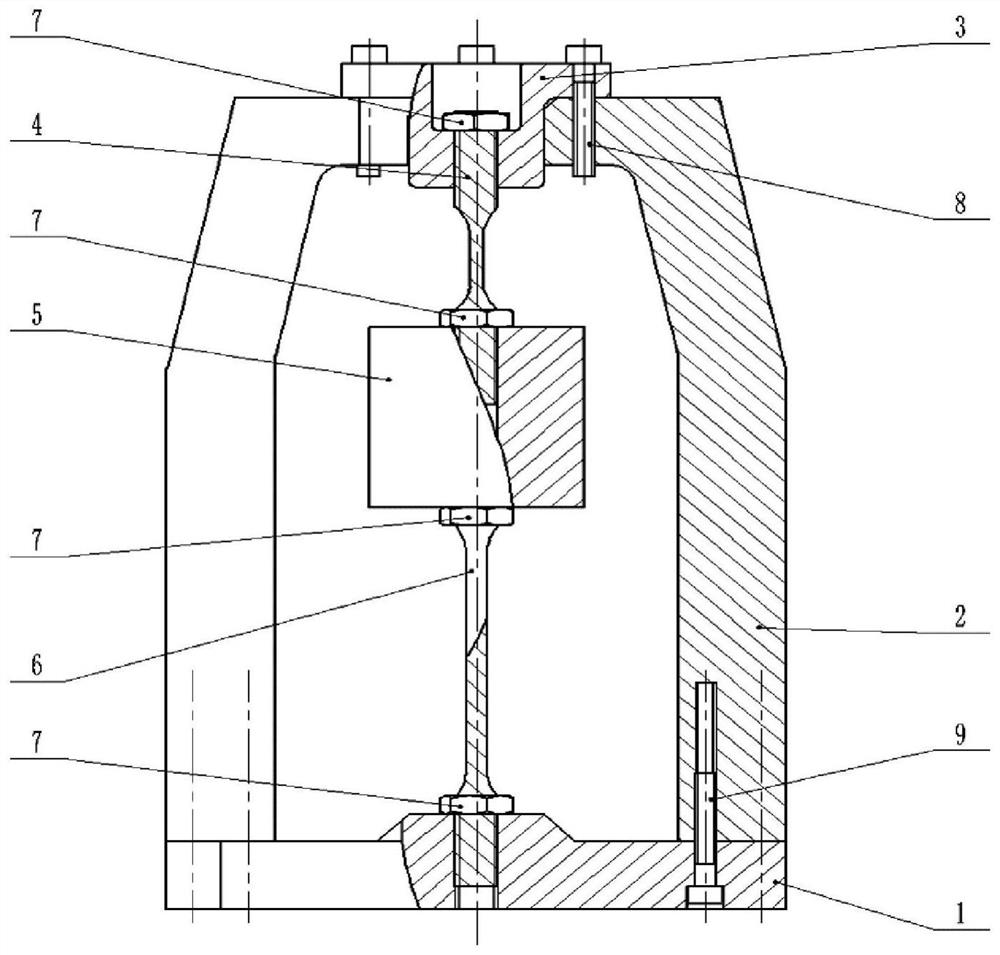

[0035] Such as figure 1 As shown, a vibration fatigue test device of the present invention that can realize the axial variable stress ratio of metal materials includes a frame bottom plate 1, a frame 2, a mass block 5, a sub-sample 6 and a locking block 3, wherein the frame bottom plate 1 is fixedly installed On a vibrating table, the frame 2 is installed on the frame bottom plate 1, the locking block 3 is installed on the top of the frame 2, the sub-sample 6 is vertically installed on the frame bottom plate 1, the upper end of the sub-sample 6 is installed with a mass block 5, the mass The sample 4 is installed between the block 5 and the locking block 3 .

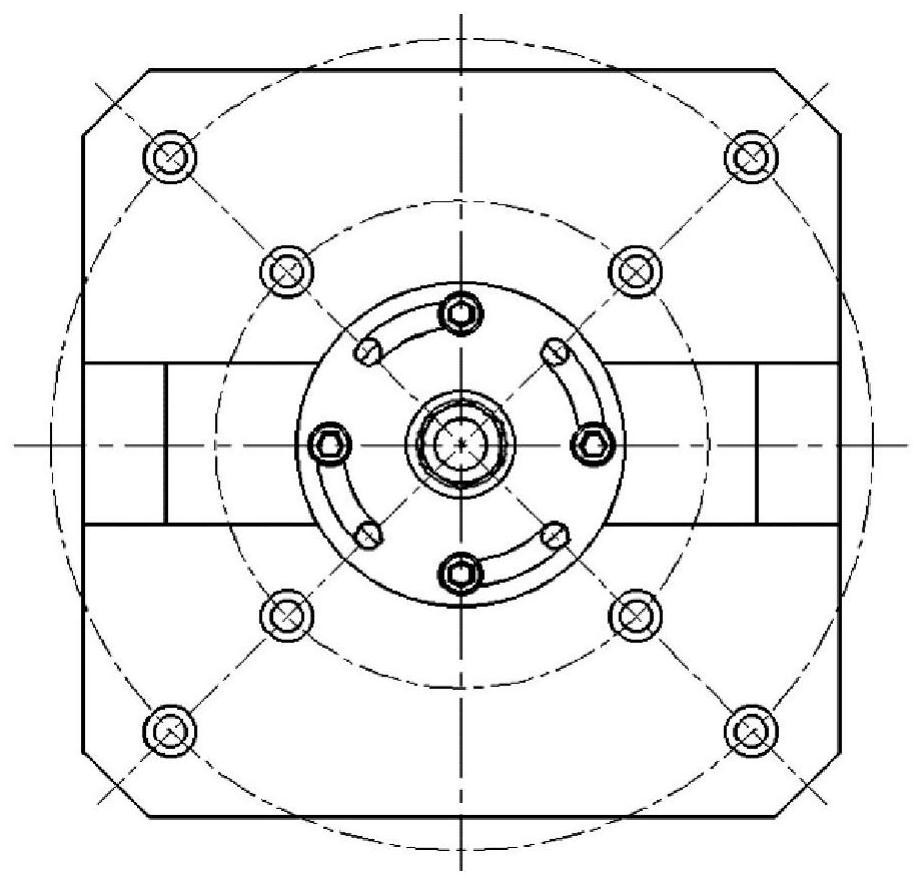

[0036] Such as Figure 2~3 As shown, the frame 2 is in the shape of an inverted U as a whole, and the top of the inverted U is provided with an opening for installing the locking block 3;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com