Protective cover for turbofan engine of aeroplane

A turbofan and protective cover technology, applied in the field of protective cover, can solve problems such as abnormal engine operation, engine damage, and stop operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

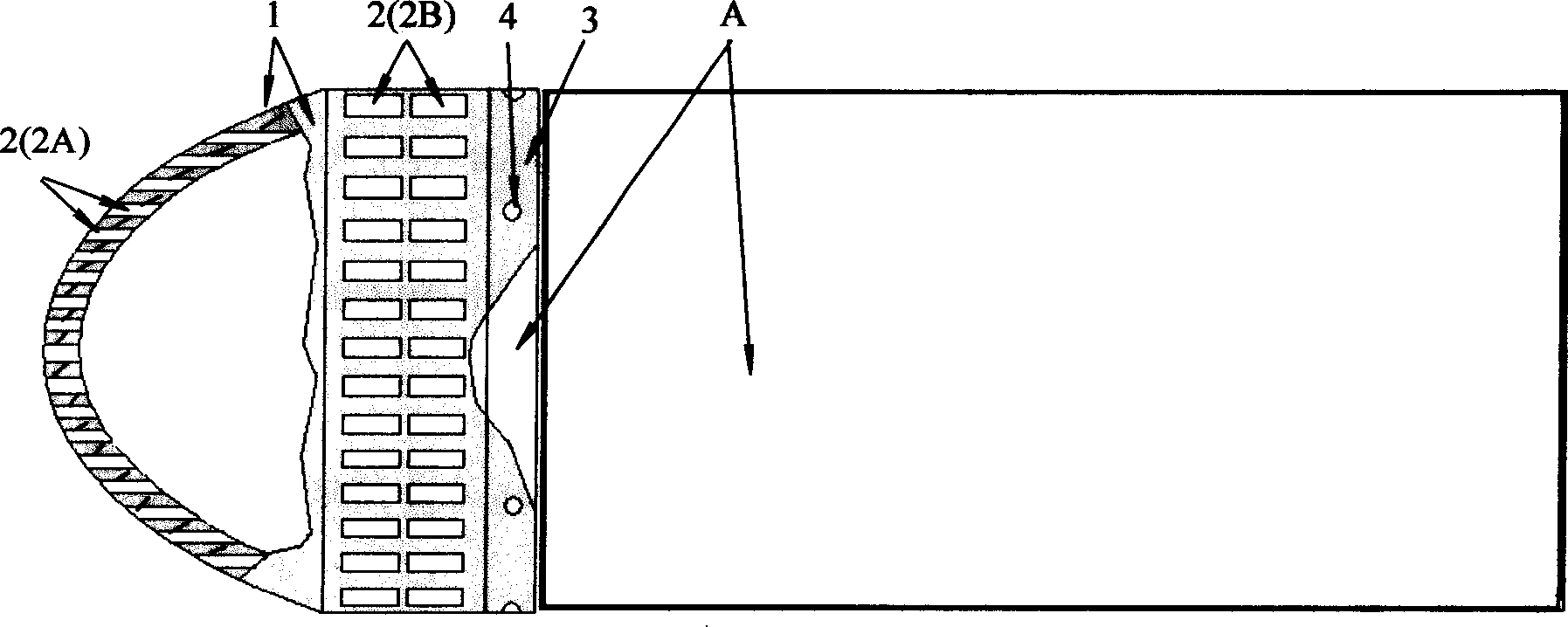

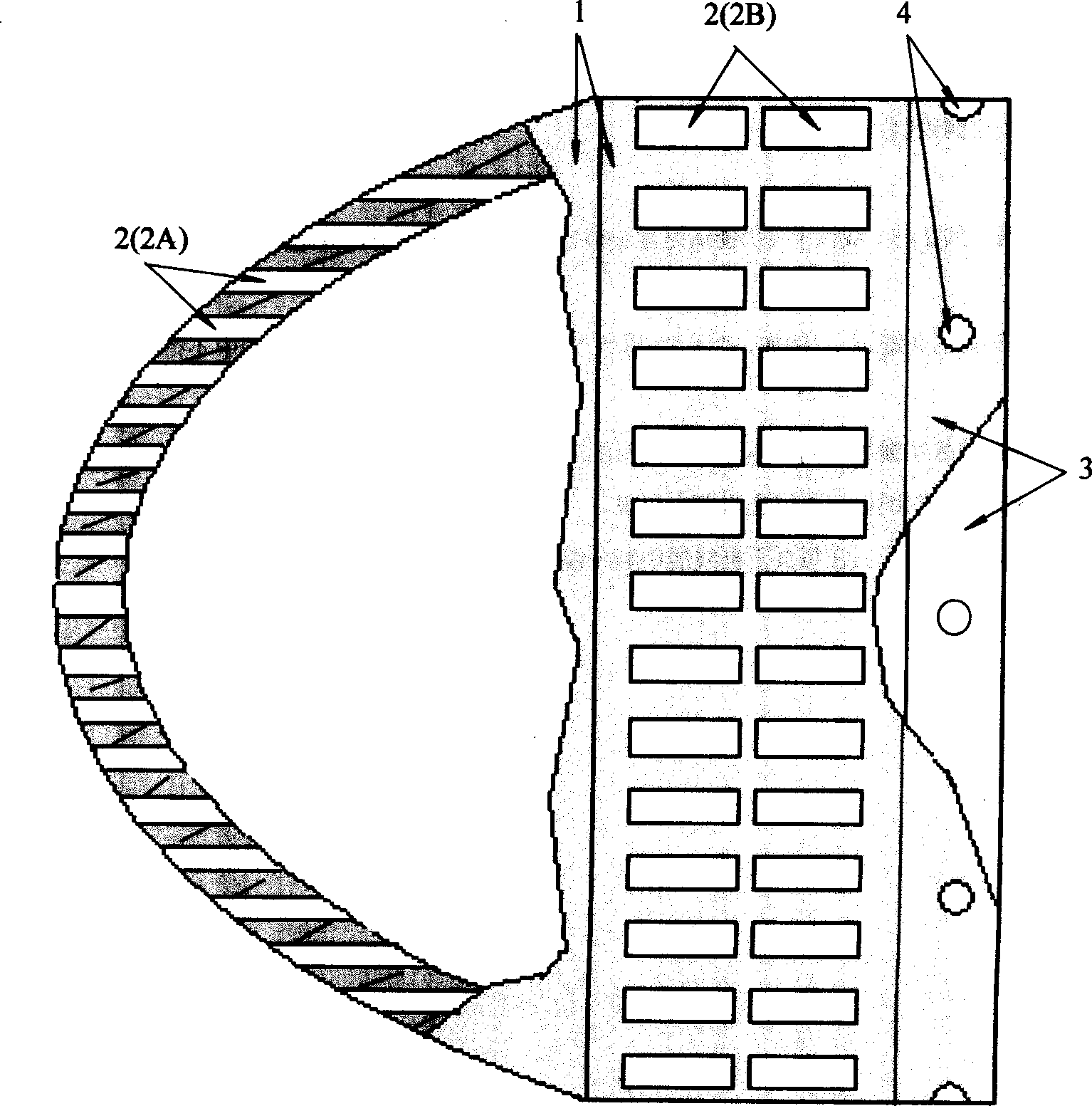

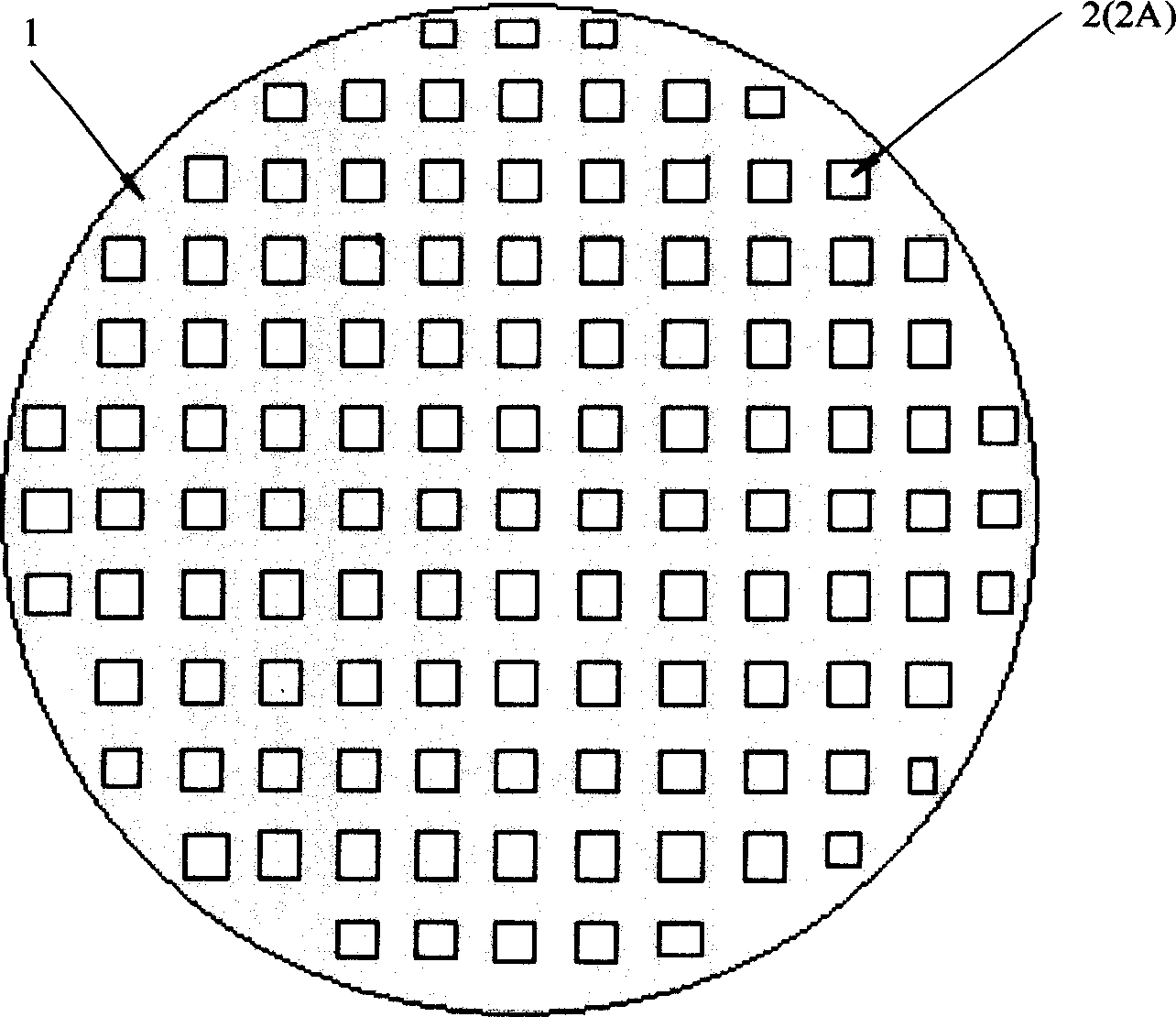

[0020] see first figure 1 , figure 2 , image 3 , the protective cover used to protect the safety of the aircraft turbofan engine, it includes a casing (1) installed on the front end of the engine (A) to protect the safety of the engine, and a casing (1) arranged on the top of the casing (1) to conduct air The air guide hole (2), a fixing belt (3) arranged at the end of the housing (1) to fix the housing (1) and a bolt hole (4) arranged on the fixing belt (3), are arranged in the housing It is connected with the inner wall of the shell and is radial, and is used to support the support frame (5) of the shell (see Figure 4 ). The air guide holes (2) include air guide holes (2A) and (2B).

[0021] The shell (1): a. It is made of metal alloy material or carbon fiber composite material with light material and high mechanical strength.

[0022] B, housing (1) profile front end is garden arc, and the middle part is garden cone, and the end is garden cylinder.

[0023] c, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com