Dynamic continuous sucking filter with cage filtering barrel

A technology of filter and squirrel cage, which is applied in the field of mechanical equipment, can solve the problems of easy to pore, the low filtration efficiency of the shaped filter cake layer, and the low filtration efficiency of normal pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

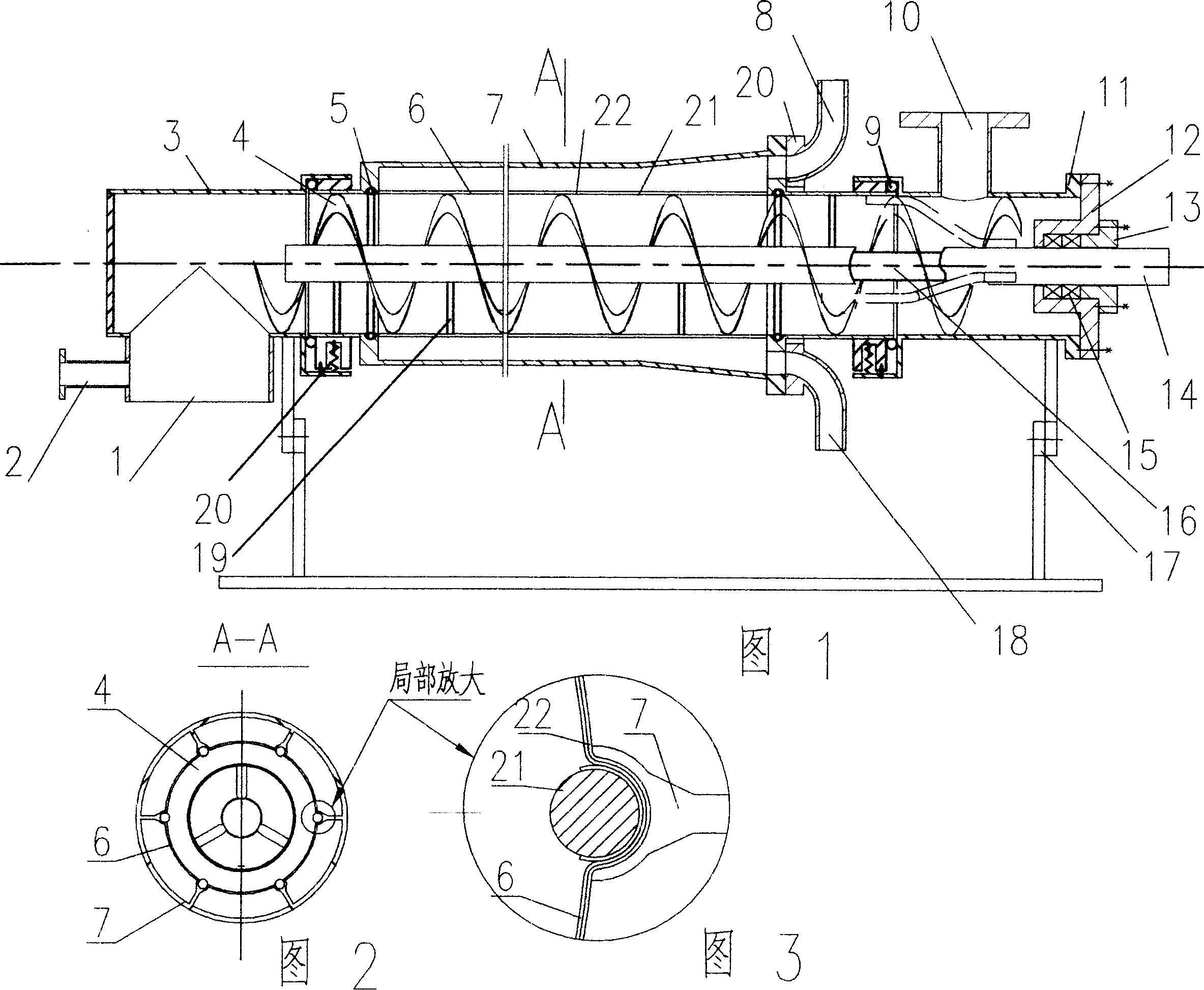

[0009] Example 1: In Figure 1, the drive shaft (14) is driven by a motor through a transmission. The motor is controlled by the control cabinet to adjust the speed of the drive shaft speed according to the meter feedback signal placed in the meter port (2). The drive shaft (14) Drag the squirrel cage filter cell (7). The squirrel cage filter cartridge unit (7) is composed of a base body, a filter medium (6), a compression rod (21), a protective net (22), and a tie ring (5). The base body of the squirrel cage filter cartridge is connected with the drive shaft (14) as a whole. The protective net (22) and the filter medium (6) are opened in the base body into a bag shape, and the pressing rod (21) presses the filter medium (6) against the base body. The two ports of the bag filter medium (6) are tied tightly Loop (5) to secure it. The spiral belt guide (4) is put into the squirrel cage filter cartridge cell (7) and rotates together with the squirrel cage filter cartridge (7). The fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com