Inclined rotary drum washing machine with pulsative wheel

A drum washing machine, tilting technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of inconvenient operation, difficult washing performance, etc., to save water, improve washing performance, and improve washing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0043] In the description of the present invention, the parts that are the same as those of the conventional technology are given the same names and reference symbols referring to the conventional technology.

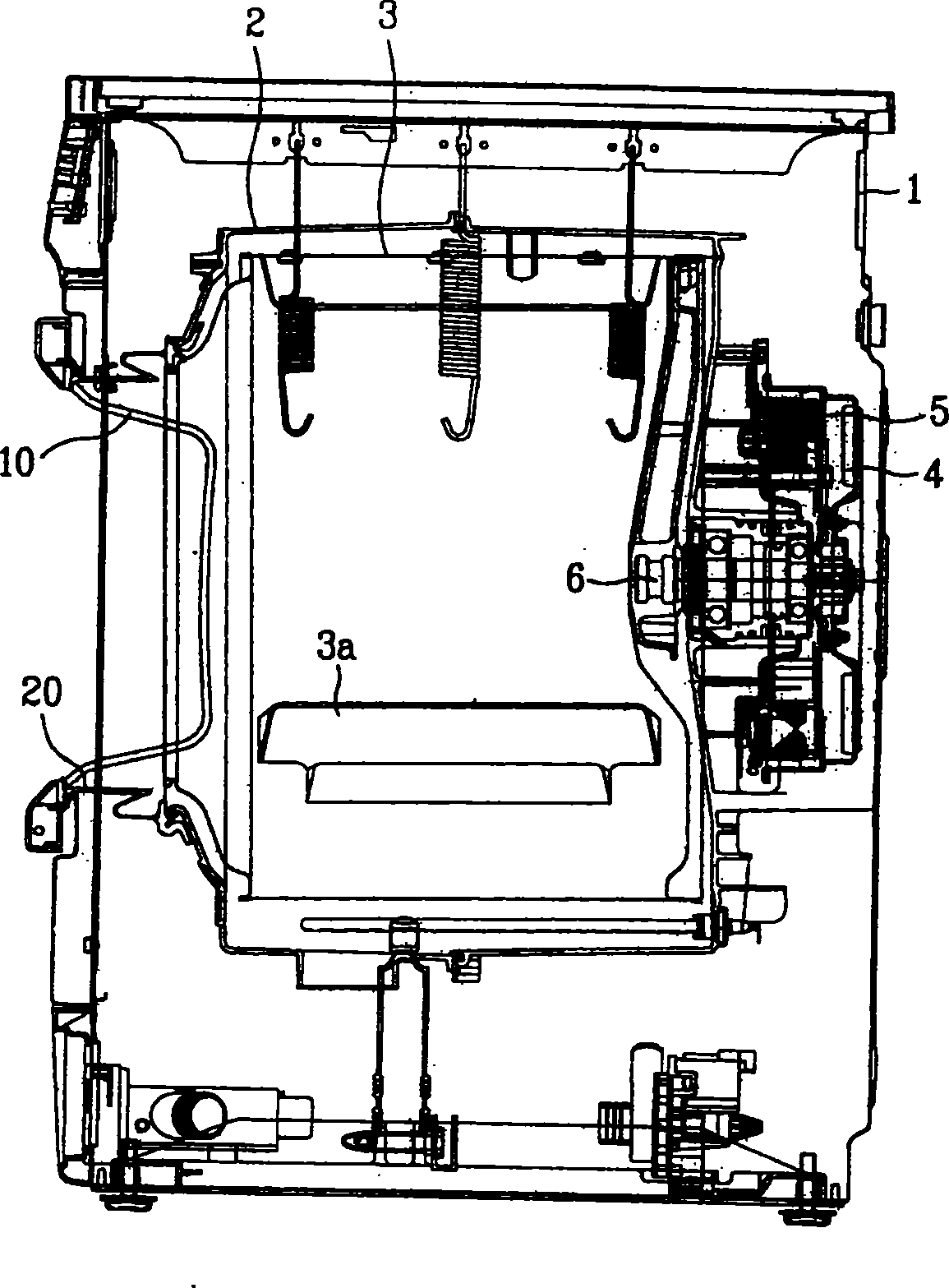

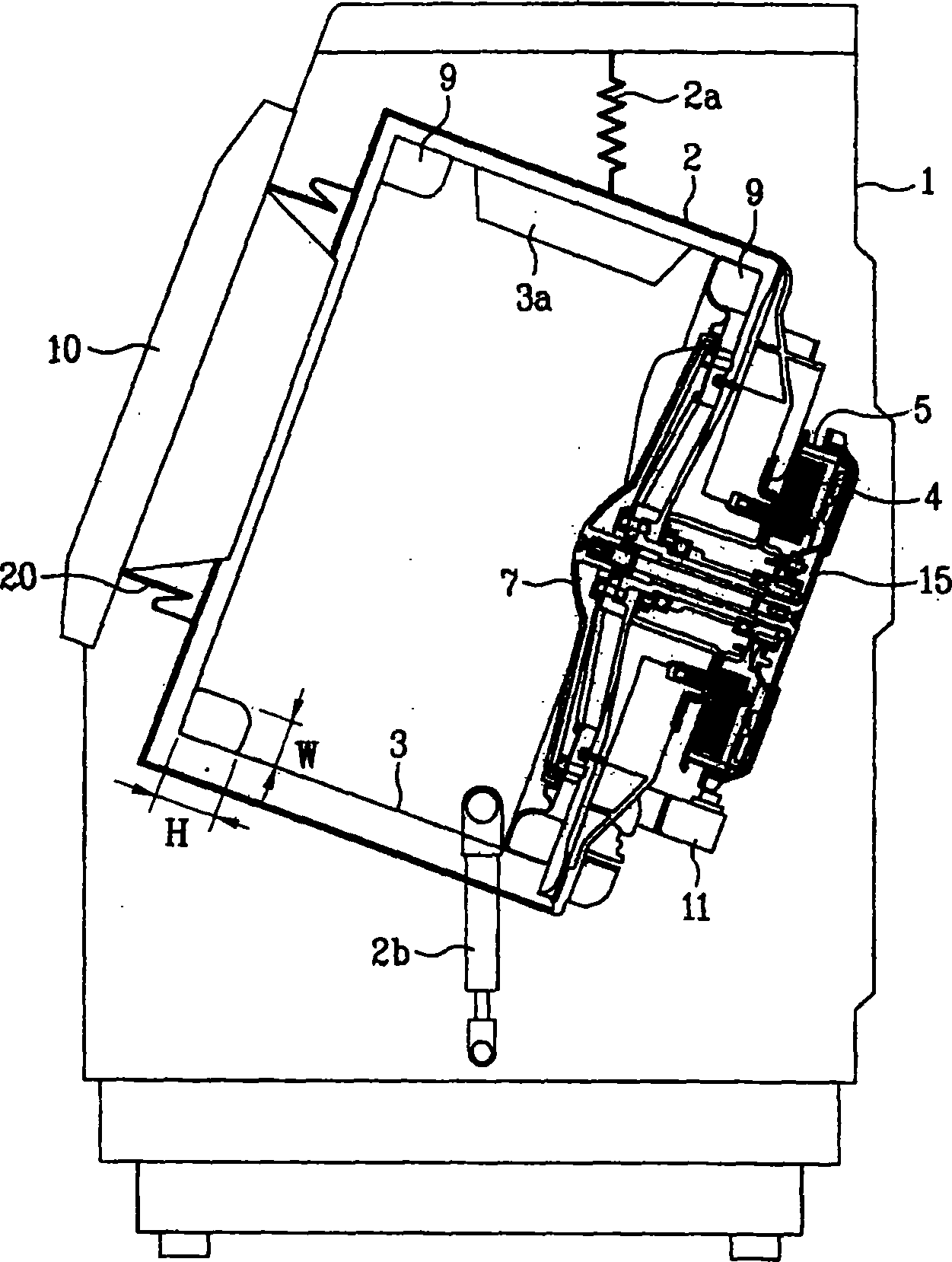

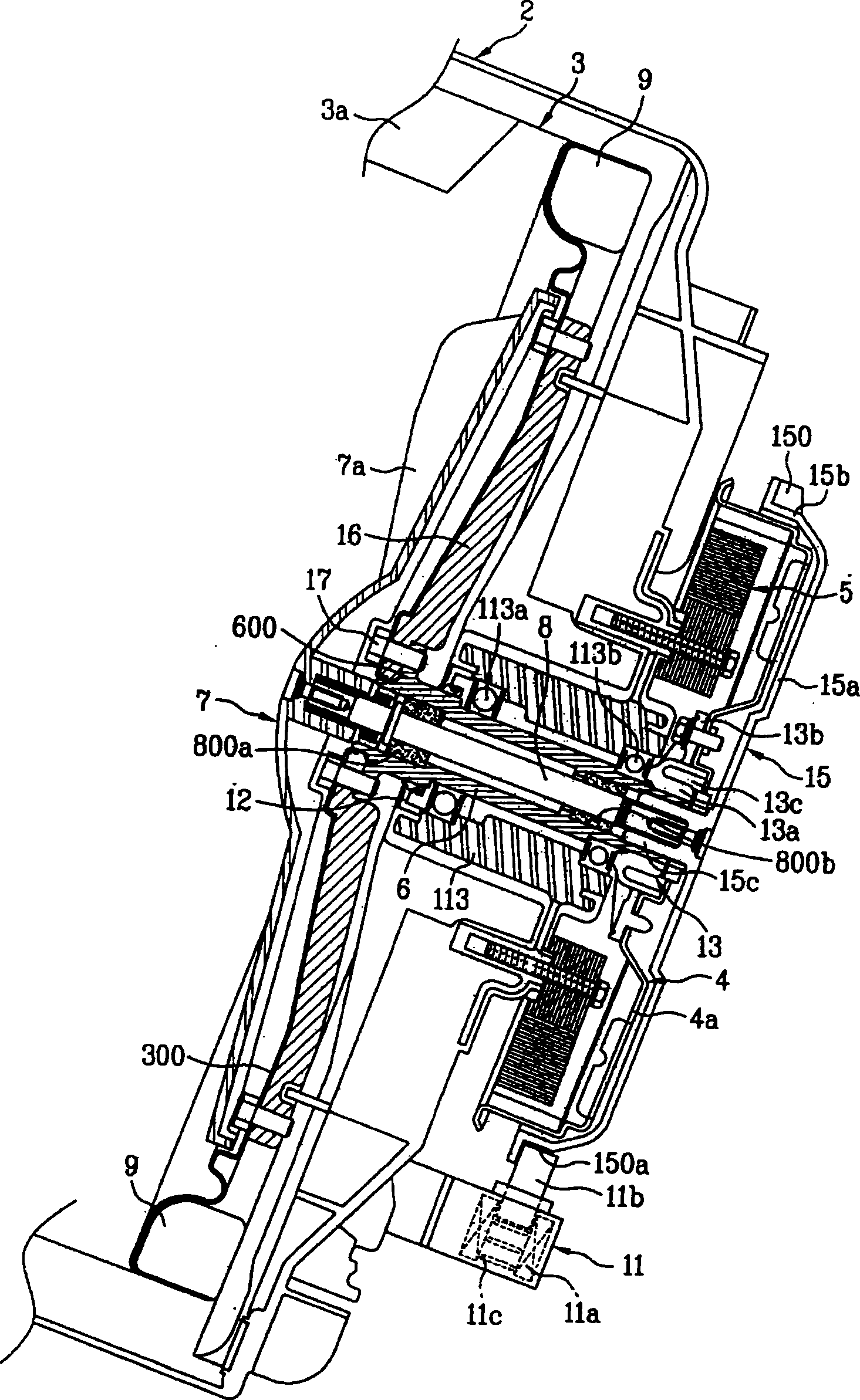

[0044] like Figures 2 to 7 As shown, the drum washing machine of the present invention includes: a plastic washing tub 2 with a wall for storing washing water and assembling a driving part, and a certain inclination angle is formed between the front side and the bottom surface; 2. The inner drum 3; runs through the washing bucket 2, and is combined with the drum 3 in a shaft connection, and the hollow drum shaft 6 that transmits the motor power to the drum 3; more than one bearing 113a, 113b supporting the hollow drum shaft 6; supporting bearings The sleeve-shaped bearing cover 113 of 113a, 113b; the stator 5 assembled on the rear wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com