Inclined rotary drum washing machine with pulsative wheel

A drum washing machine and pulsator technology, applied in the drum washing machine field, can solve problems such as difficult to obtain washing effect and inconvenient operation, and achieve the effects of improving washing performance, saving water consumption, improving drying efficiency and drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

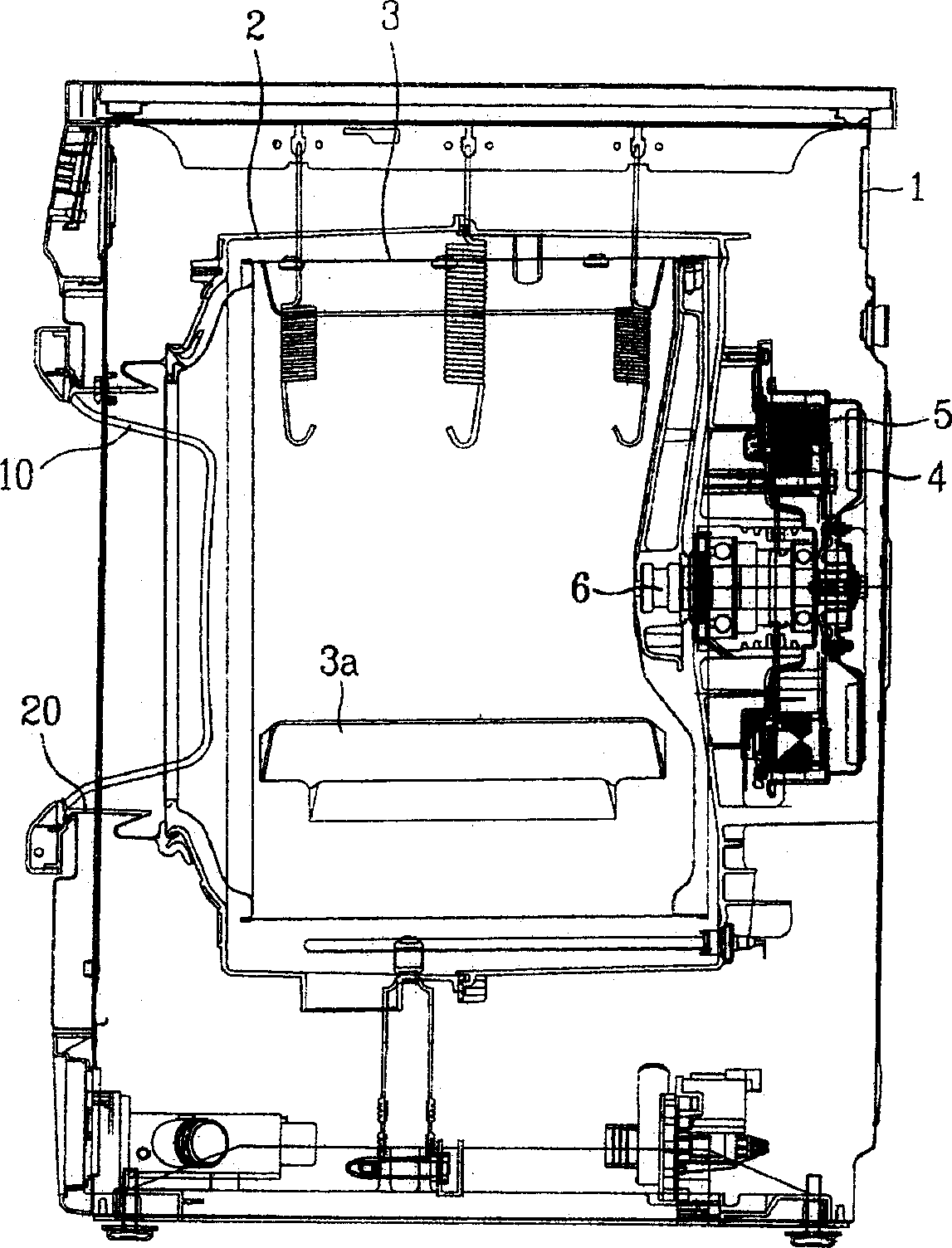

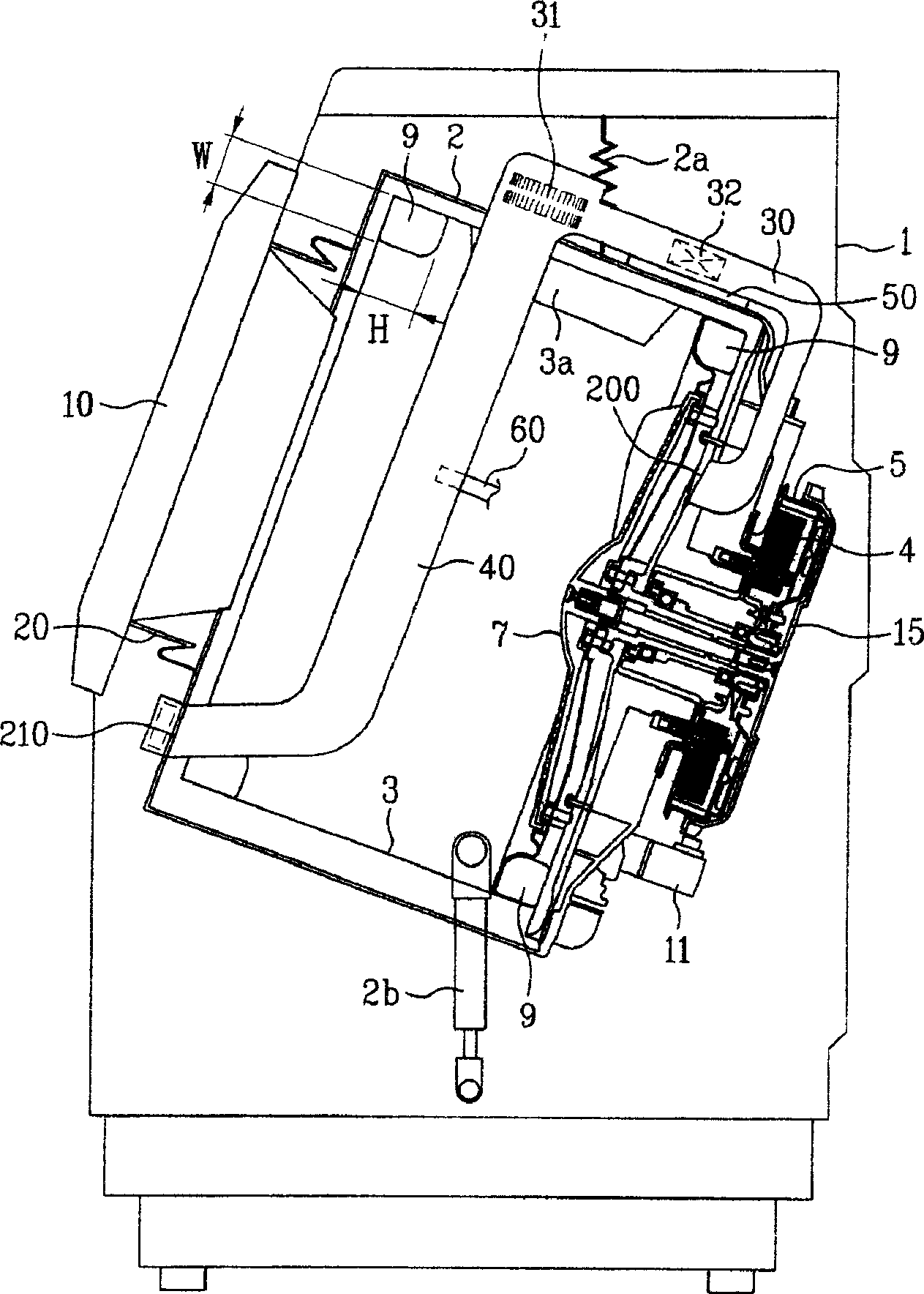

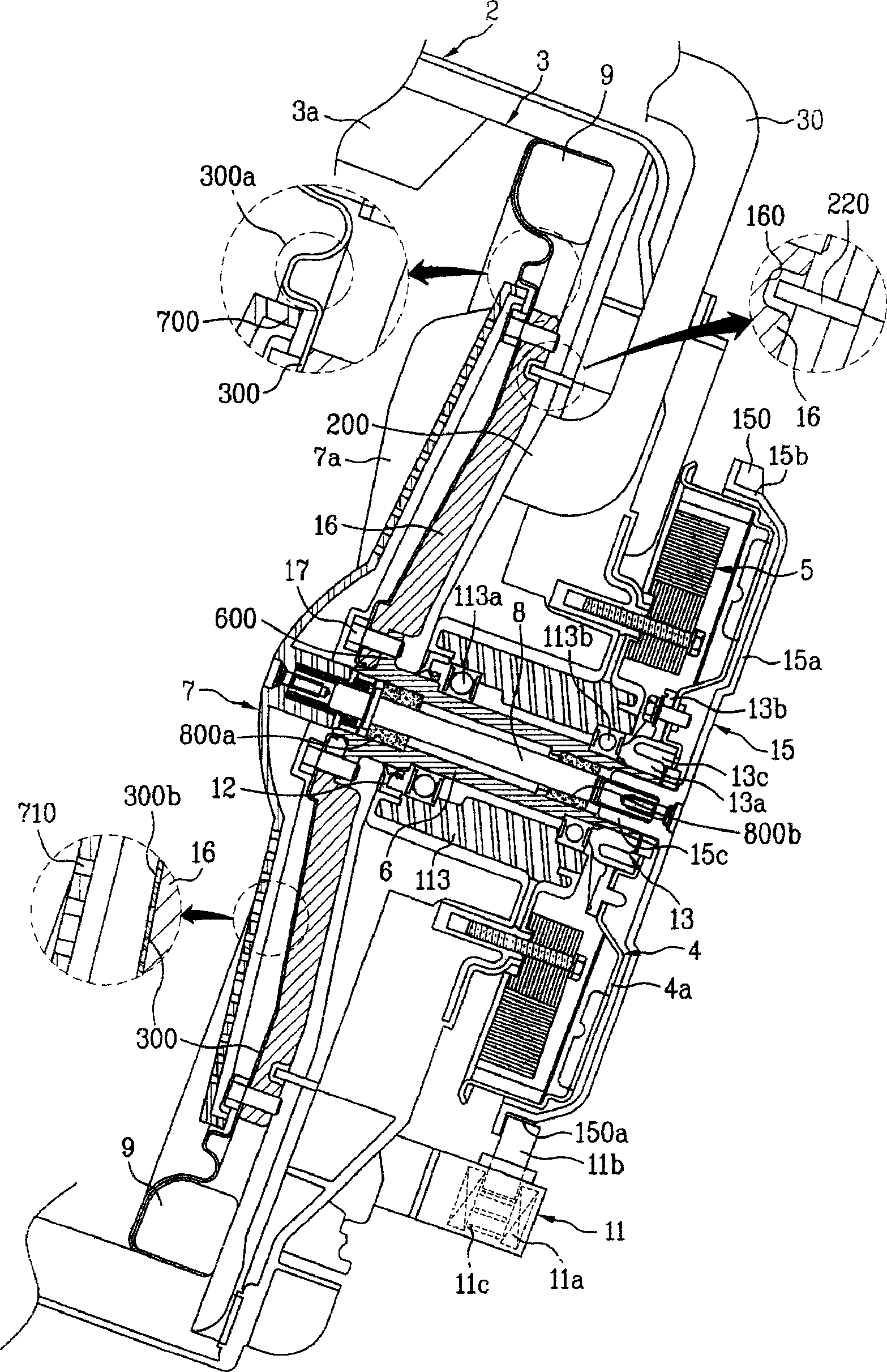

[0055] Refer below Figure 2 to Figure 7 , the inclined drum washing machine of the present invention will be described in detail.

[0056] For reference, in the description of the present invention, the same components as those in the conventional technology have the same names and the same reference numerals.

[0057] Such as Figure 2 to Figure 7 As shown, the drum washing machine of the present invention includes: a wall portion for storing washing water and assembling the driving part, and a certain inclination angle is formed between the front and the ground, and a hot air inlet 200 is formed on the upper side of the rear wall surface. The plastic material outer tub 2 that is formed with the hot air outlet 210 on the lower front side; is rotatably arranged on the inner side of the outer tub 2, and is formed with a drum 3 with a hot air circulation hole 300b on the rear wall; a heater 32 and The blower fan 31 is used to generate hot air, and is fixed on the drying duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com