Lift device for industrial vehicle

A technology for industrial vehicles and hoses, used in lifting devices, portable lifting devices, hoisting devices, etc., can solve problems such as laborious, inability to smoothly guide hoses, and leakage of hydraulic fluid or hydraulic oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

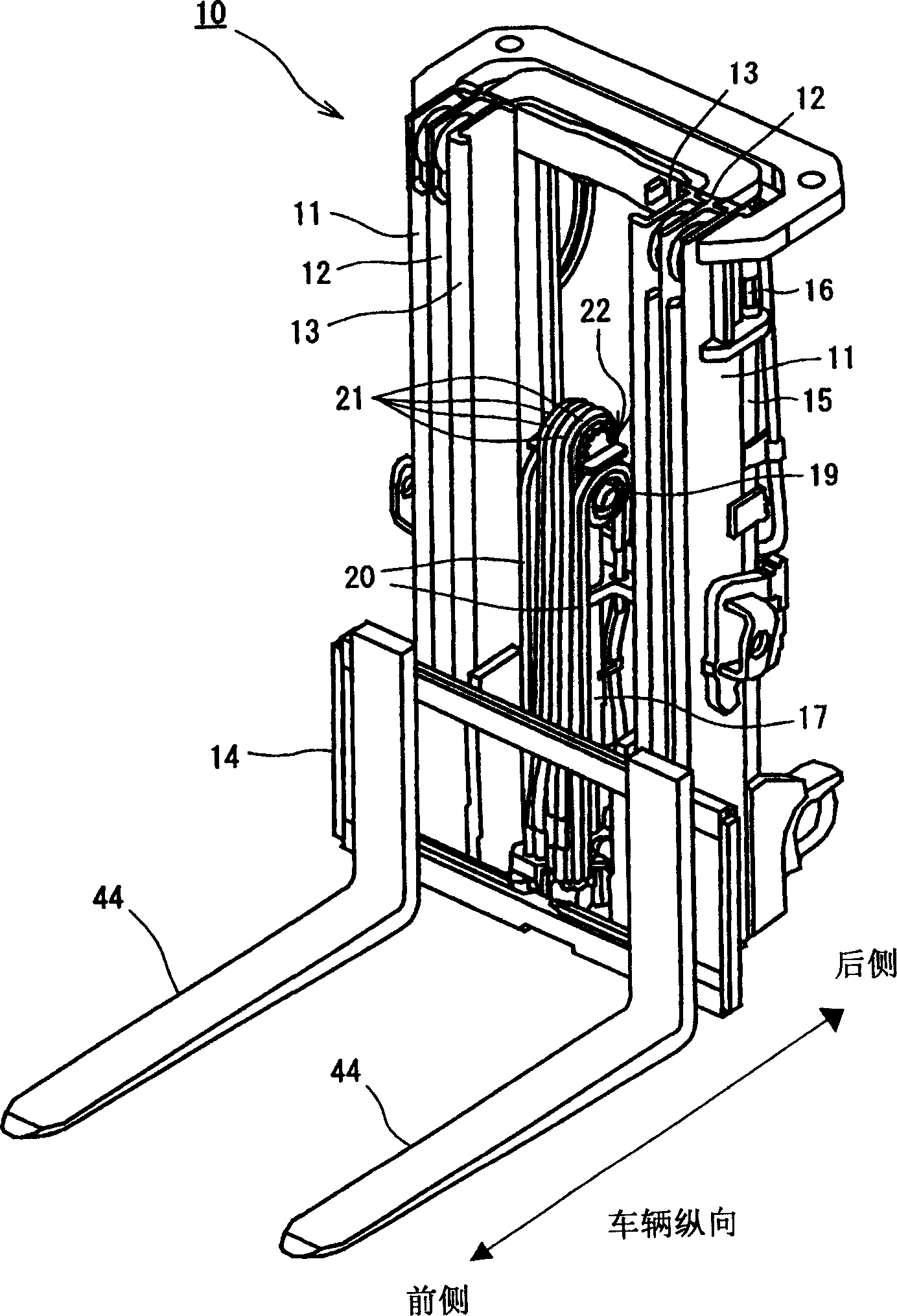

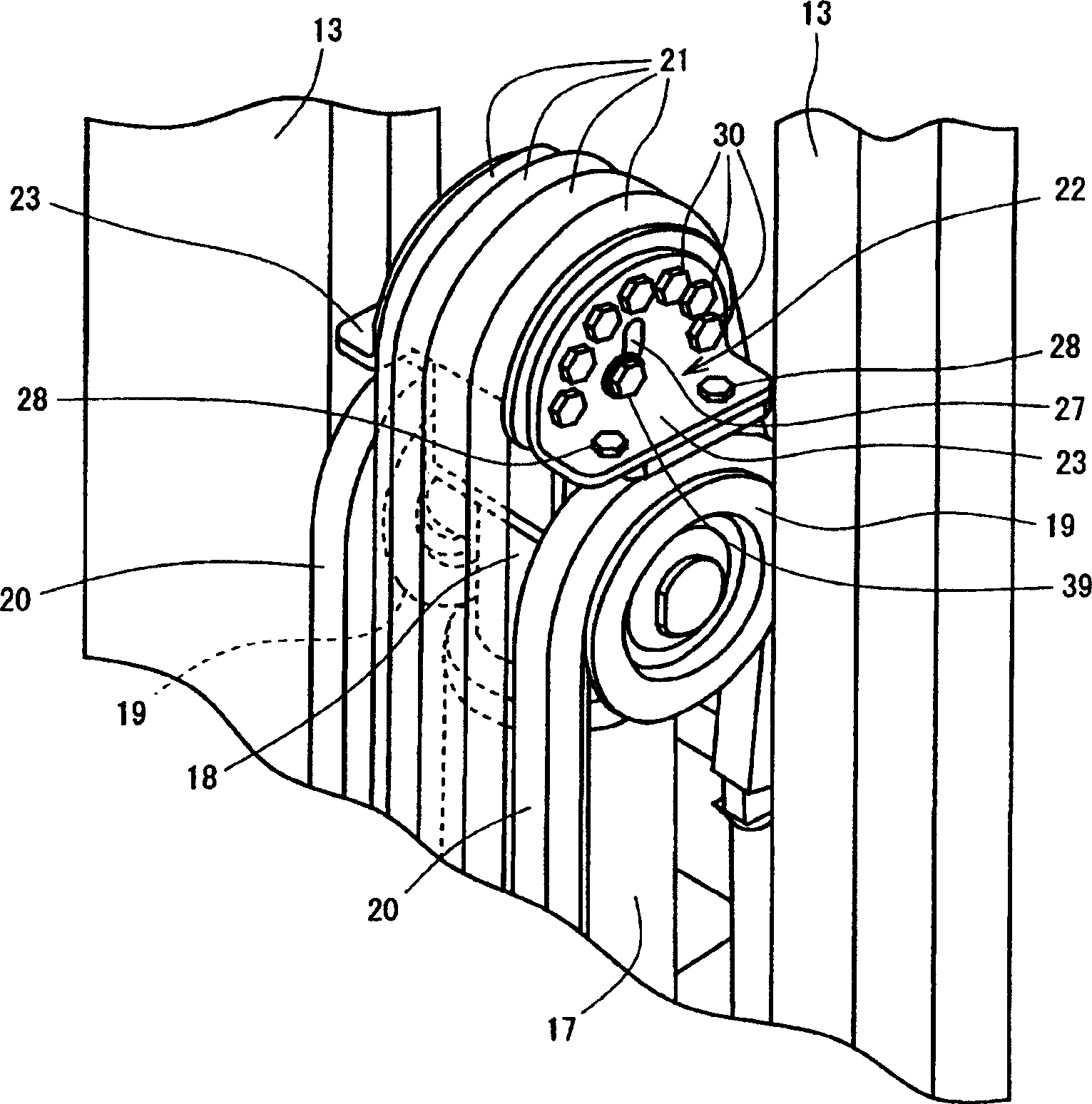

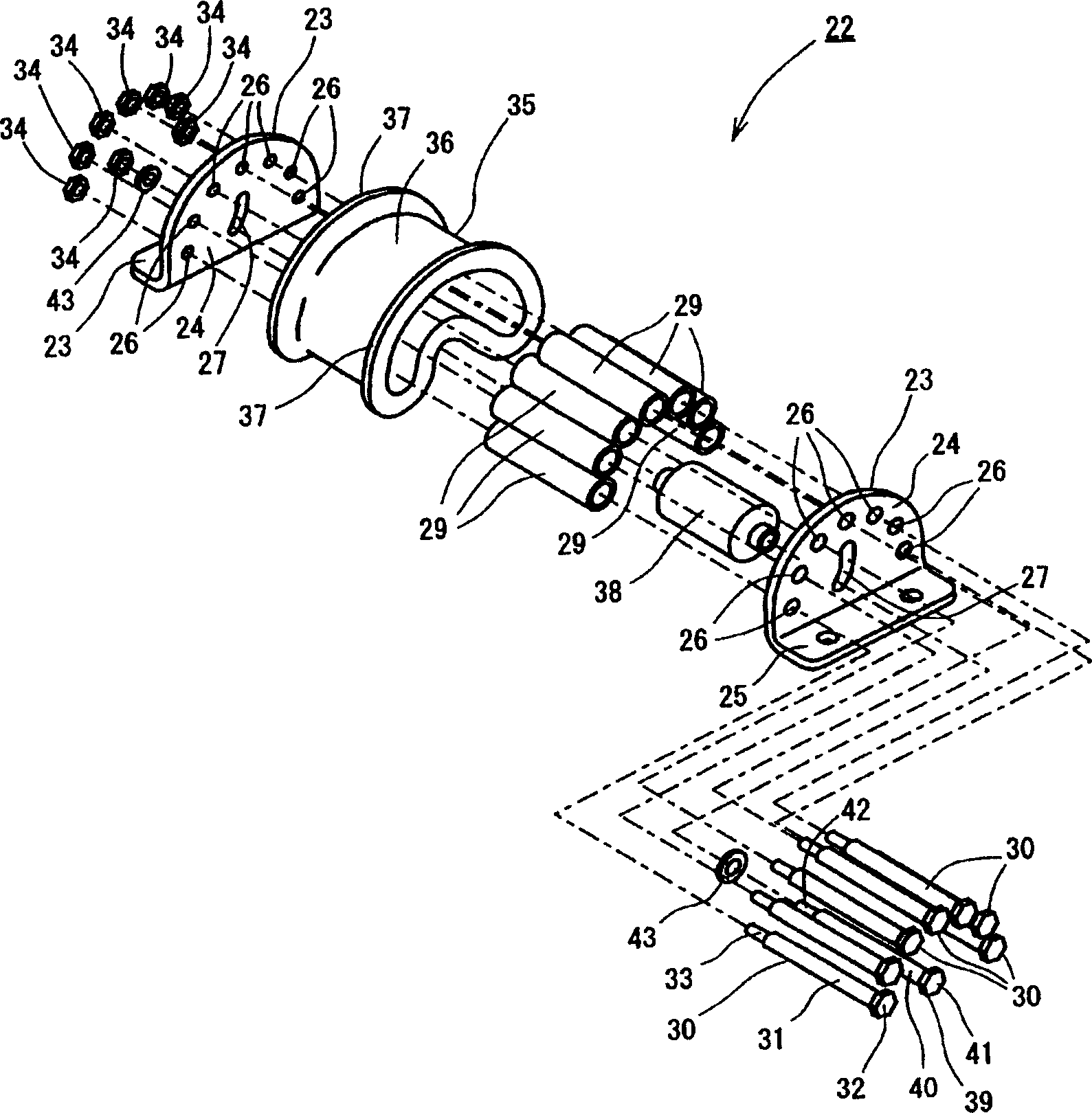

[0017] Below, refer to Figure 1 to Figure 5 , describing a lifting device for an industrial vehicle according to a preferred embodiment of the present invention. The lifting device 10 of the preferred embodiment is designed for a three-section full free-lift column forklift as an industrial vehicle. figure 1 An isometric view of the lifting device 10 is shown. Such as figure 1 As shown, the lifting device 10 includes: a pair of laterally divided outer pillars 11 disposed at the front of the vehicle; and a pair of transversely divided center pillars 12 disposed inside the outer pillars 11 . The central column 12 can move up and down along the outer column 11 . The lifting device 10 includes a pair of transversely spaced inner uprights 13 disposed on the inner side of the center upright 12 . The inner column 13 can move up and down along the central column 12 . The lifting device 10 also includes a lifting bracket 14 , and the lifting bracket 14 is arranged on the inner co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com