Lever and floating steam trap of balanced and two-valve seat

A double-seat, float-type technology, applied in steam traps, mechanical equipment, etc., can solve the problems of poor stability and reliability, and achieve the effects of pressure balance, good stability and reliability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

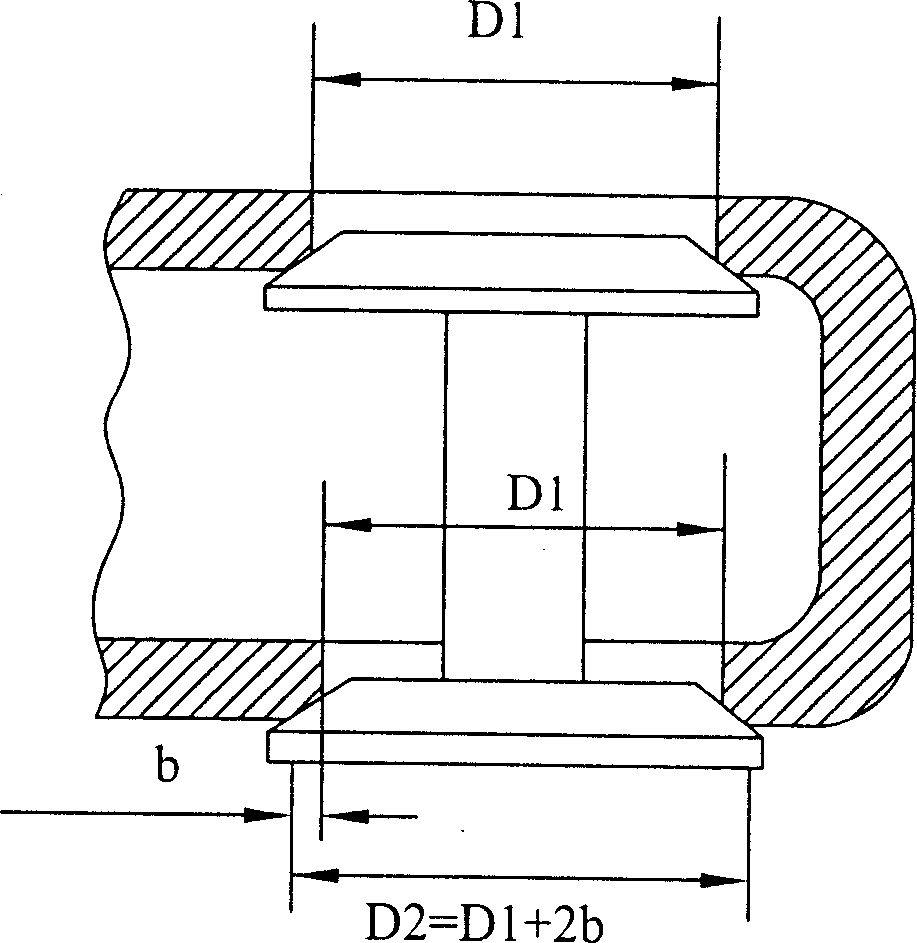

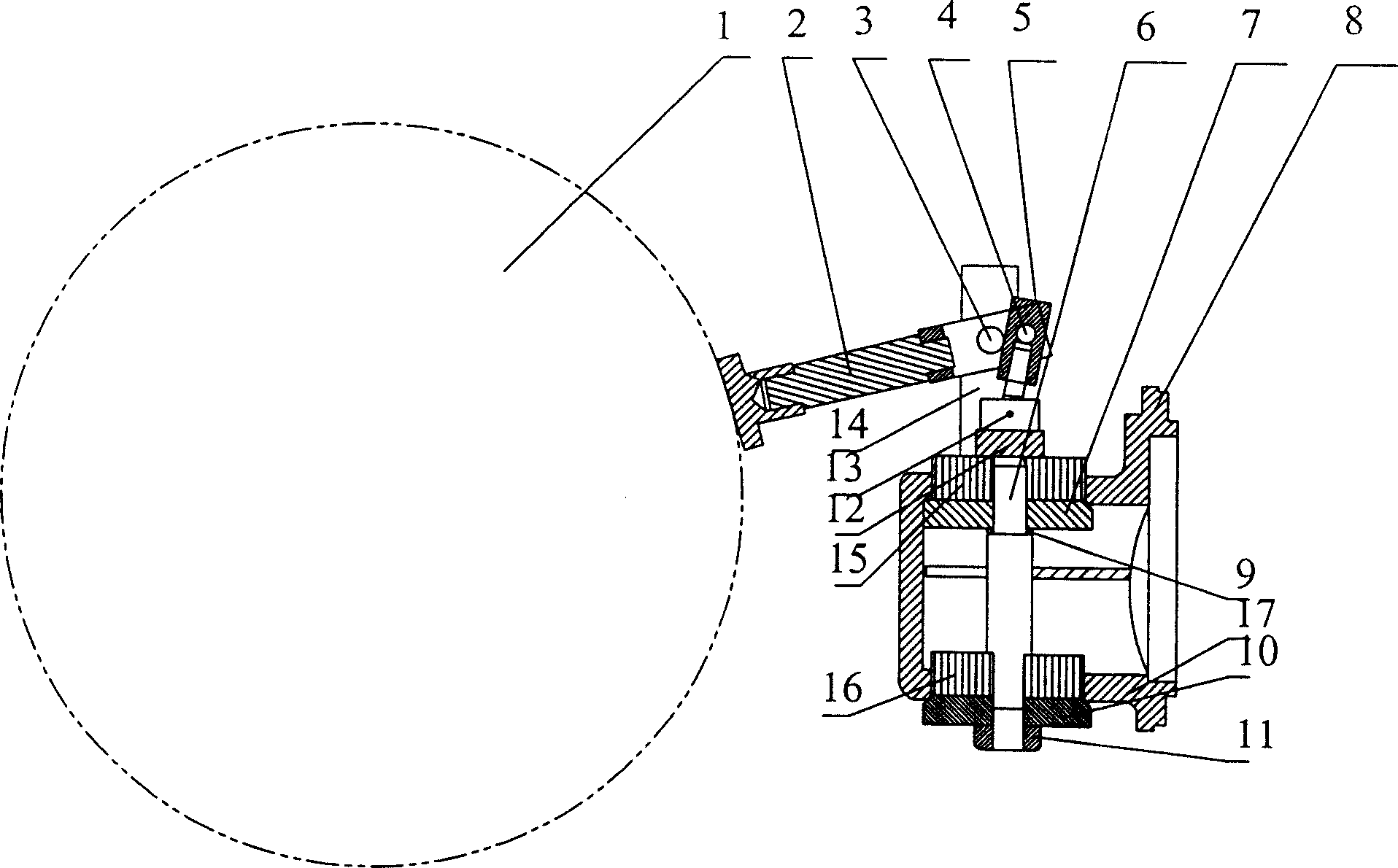

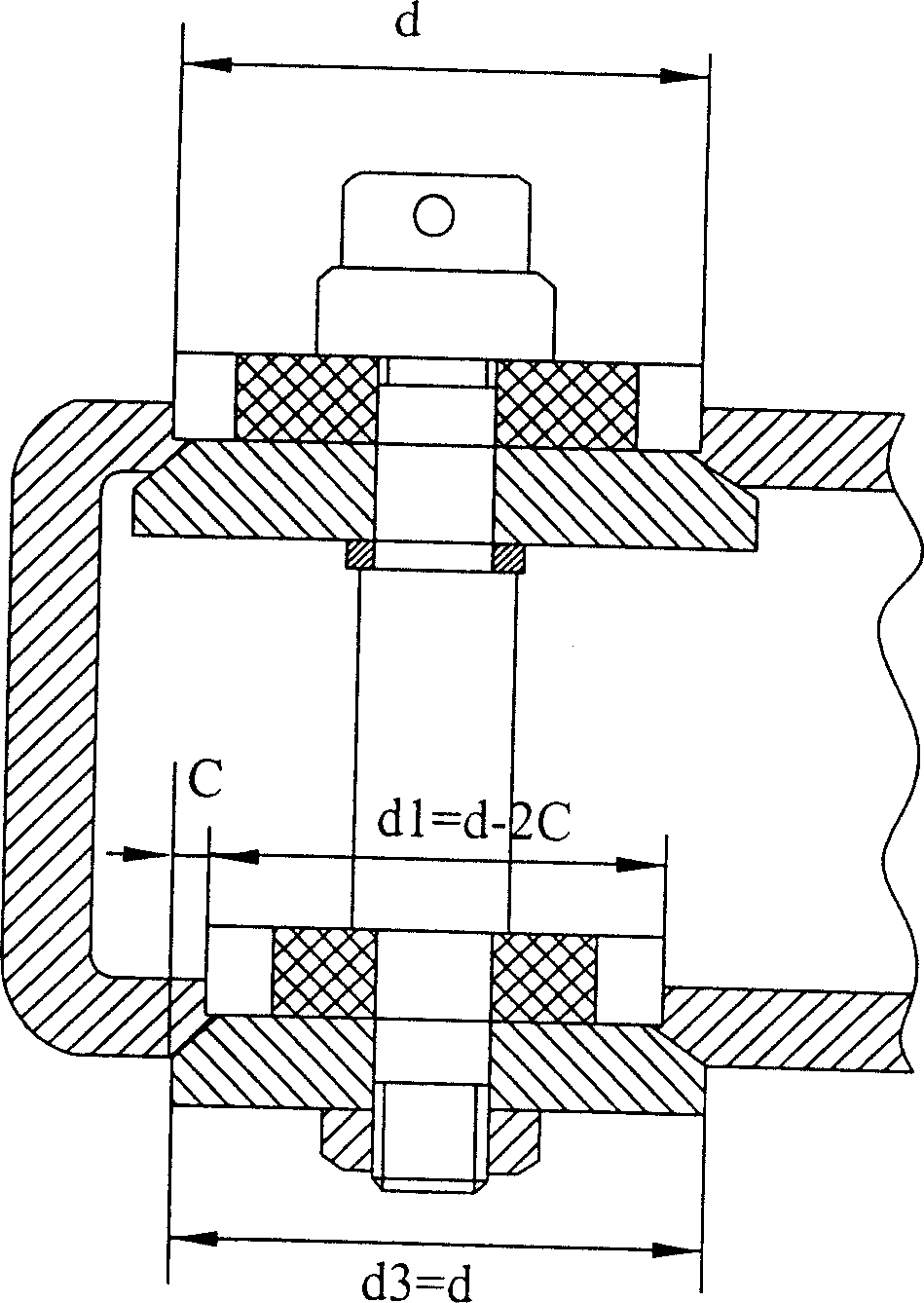

[0012] Such as figure 2 , shown in 3, is provided with float 1, lever 2, pin shaft 3, pin 4, connecting rod 5, valve stem 6, upper valve core 7, upper valve core positioning block 15, upper valve seat 8, gasket 9, Lower spool 10, lower spool positioning block 16, lower valve seat 17, nut 11, coupling head 12, coupling pin 13 and lever support 14. One end of the lever 2 is connected with the floating ball 1, the other end of the lever 2 is connected with the upper end of the connecting rod 5 with the pin 4, the lever 2 is matched with the pin shaft 3 and supported on the lever bracket 14, and the lever bracket 14 is set on the upper valve seat Above 18, the lower end of the connecting rod 5 is matched with the connecting head 12 through the connecting pin 13, the gasket 9, the upper valve core 7 and the upper valve core positioning block 15 are inserted into the upper part of the valve stem 6, and the upper valve core 7 is set on the upper valve seat 8 and matched with the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com