Water-proof mechanism of dust collector generator chamber

A technology for motor rooms and vacuum cleaners, applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve the problems of low safety, easy damage to the motor, inconvenient airflow, etc., and achieve the effect of enhancing the safety of use and high-efficiency heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

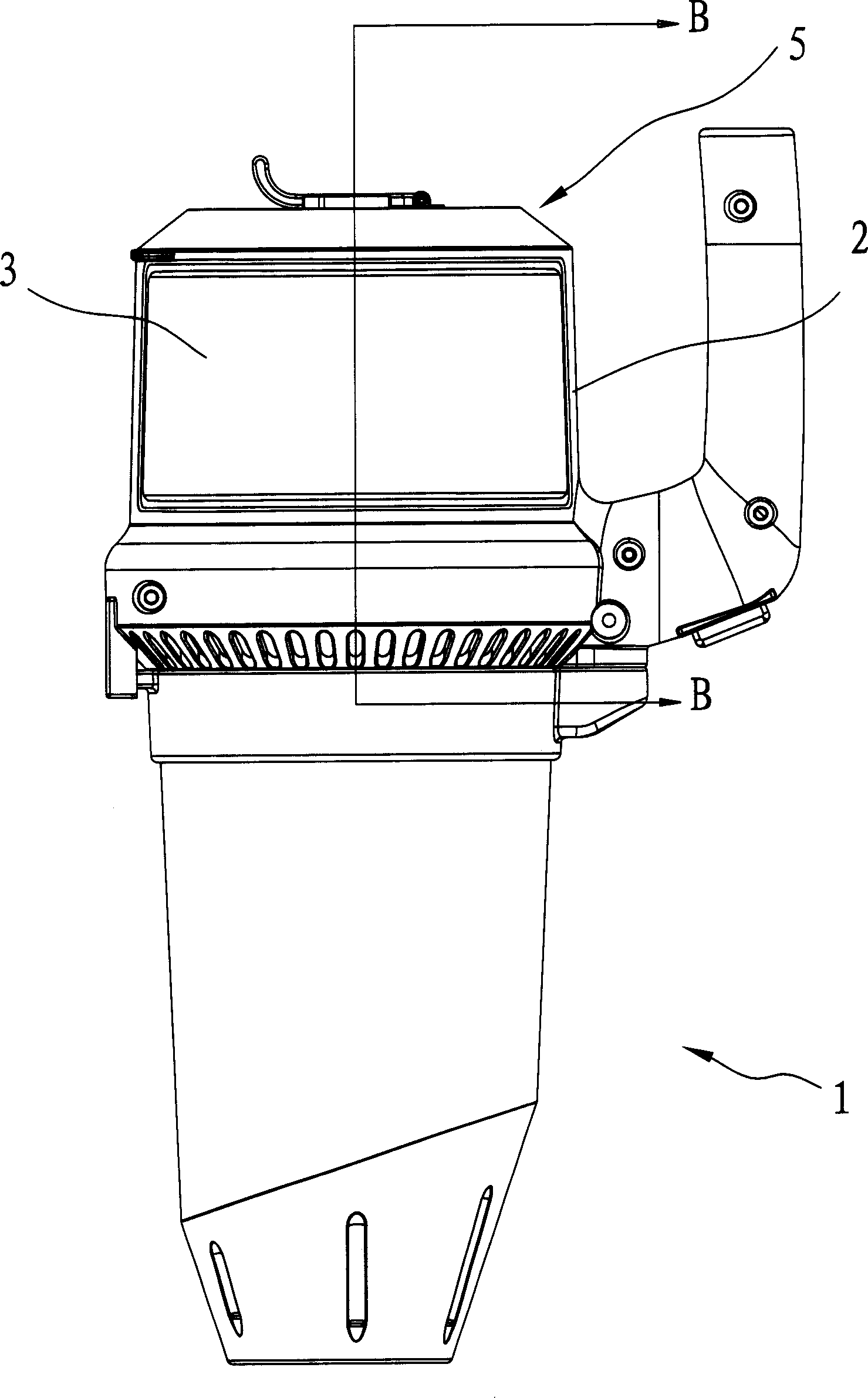

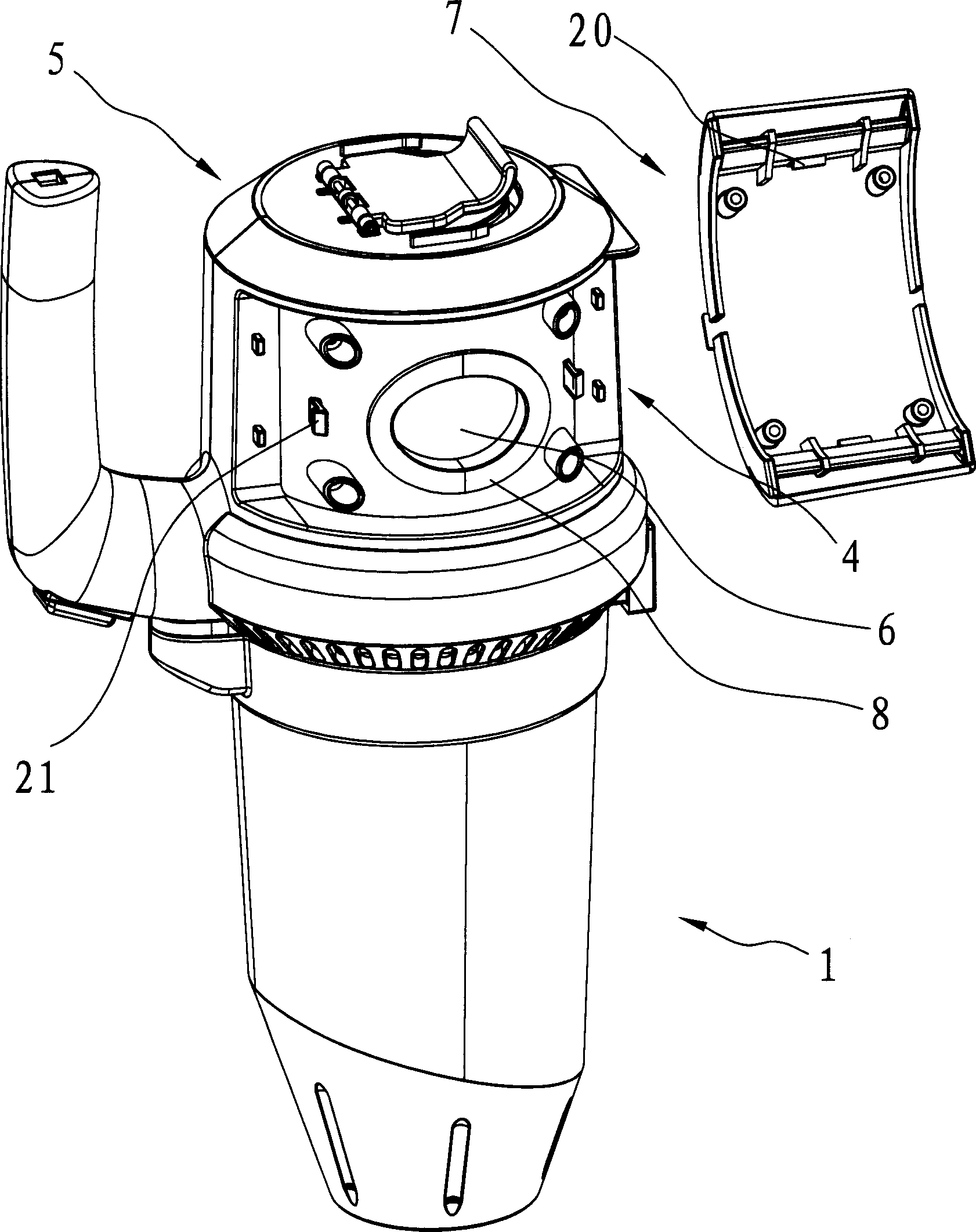

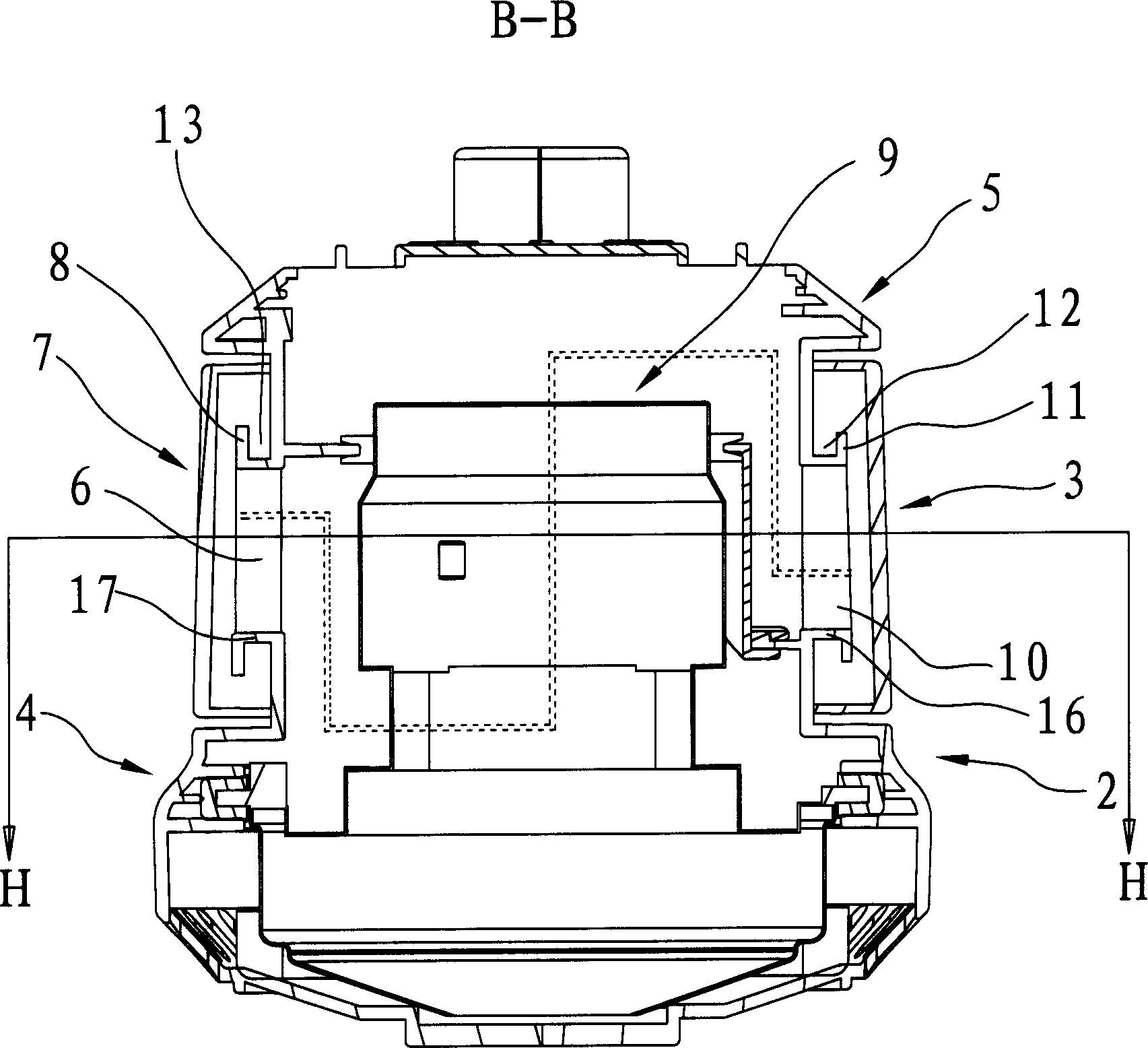

[0017] See attached figure 1 - attached Figure 4 As shown, a waterproof mechanism for the motor room of a vacuum cleaner includes a motor cover 5 with a cavity, and the motor cover 5 is provided with a heat dissipation air inlet 10 and a heat dissipation air outlet 6, and the outer side of the heat dissipation air inlet 10 is provided with The first water shielding cover 3 and the second water shielding cover 7 are arranged on the outer side of the heat dissipation air outlet 6 . The waterproof mechanism has an air inlet passage 14 and an air outlet passage 15, the air inlet passage 14 is formed between the first water shield cover 3 and the motor cover 5, and the air outlet passage 15 is formed between the second water shield Between the cover 7 and the motor cover 5, the heat dissipation air inlet 10 communicates with the space outside the first water shield cover 3 through the air inlet passage 14, and the heat dissipation air outlet 6 communicates with the second water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com