Roller set

A technology of roller group and tension spring, applied in textiles and papermaking, weft knitting, knitting, etc., can solve problems such as waste, and achieve the effect of saving cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

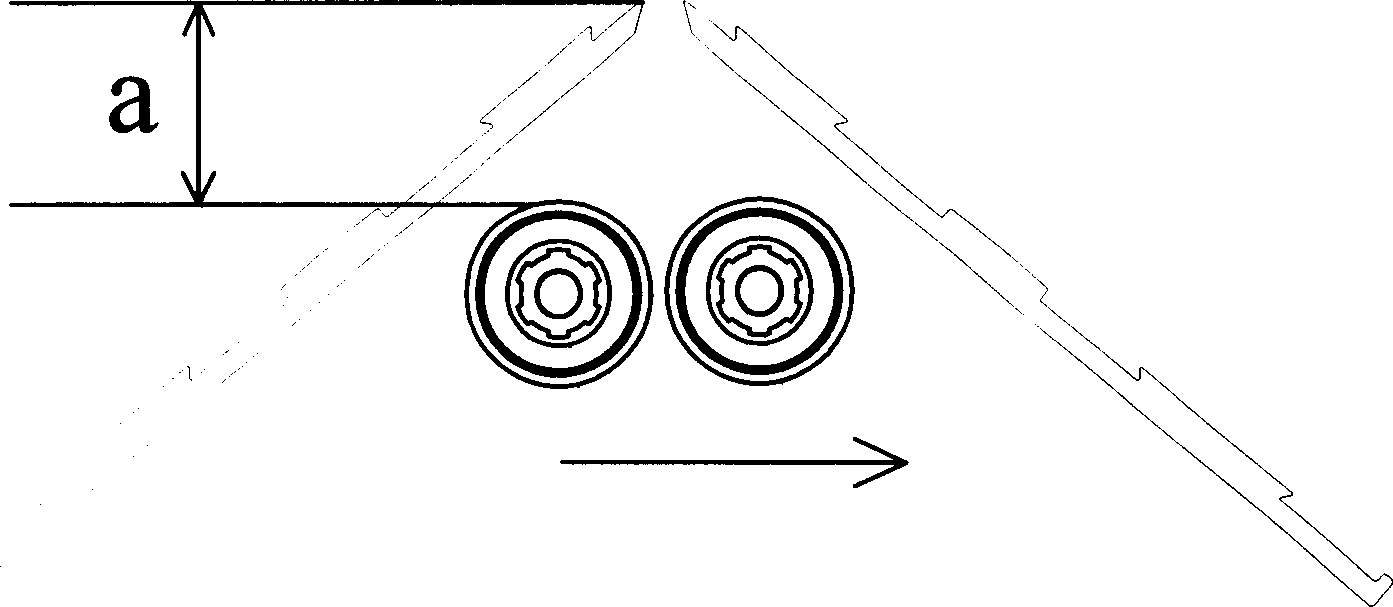

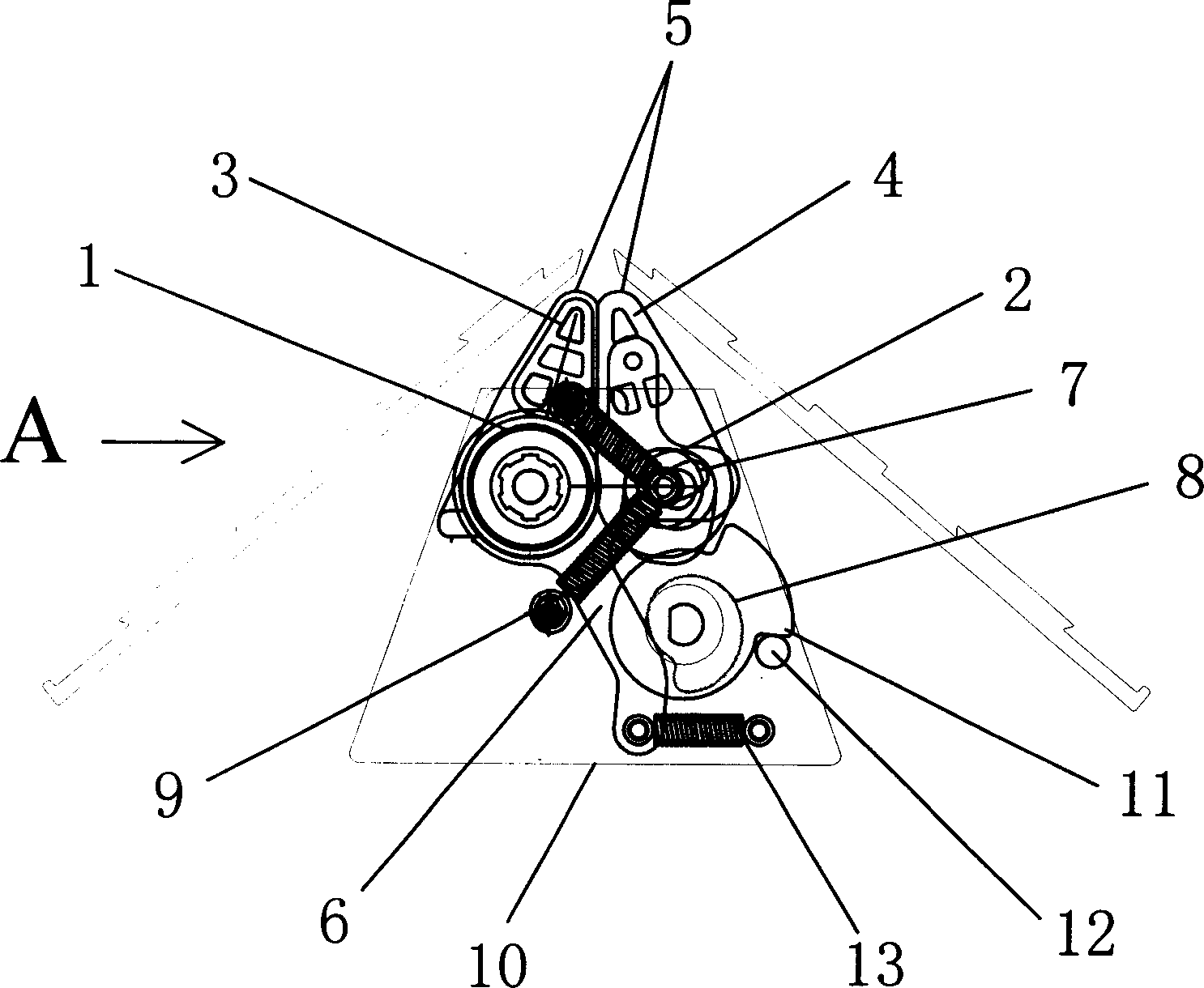

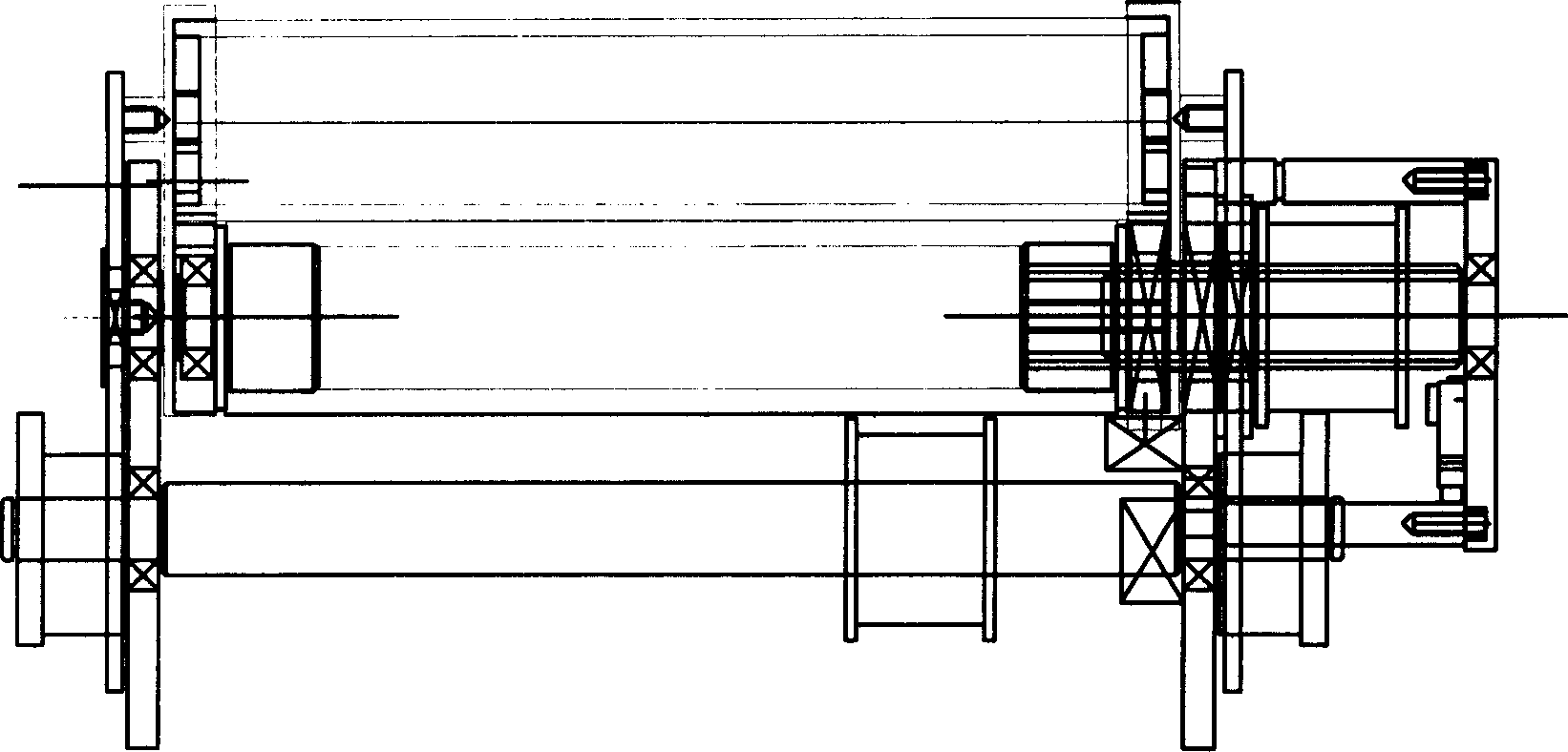

[0017] See Figure 2 to Figure 5 The roller set of the present invention comprises a driving roller 1 with a fixed shaft and a driven roller 2 with a movable shaft, and a driving chuck 3 and a driven chuck 4 are respectively arranged above the two shaft ends of the driving roller 1 and the driven roller 2, The periphery of the driving roller 1 and the driving chuck 3, the driven roller 2 and the driven chuck 4 are respectively covered with a circle of soft material 5, and the soft material 5 is made into a circumferentially sealed type, and then put on the driving roller 1 and the driving chuck 3 , the periphery of the driven roller 2 and the driven chuck 4, so that when the driving roller 1 and the driven roller 2 rotate, it can drive the soft material 5 to circulate, and the soft material 5 moves along the driving chuck 3 and the driven chuck 4 slide downward between the active chuck 3 and the driven chuck 4, if the cloth is placed between the active chuck 3 and the driven c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com