Filter element

A filter unit and filter medium technology, applied in the direction of filtration separation, membrane filter, cartridge filter, etc., can solve the problems of flammability hazards, damage to oil filter medium materials, etc., and achieve the effect of avoiding voltage peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

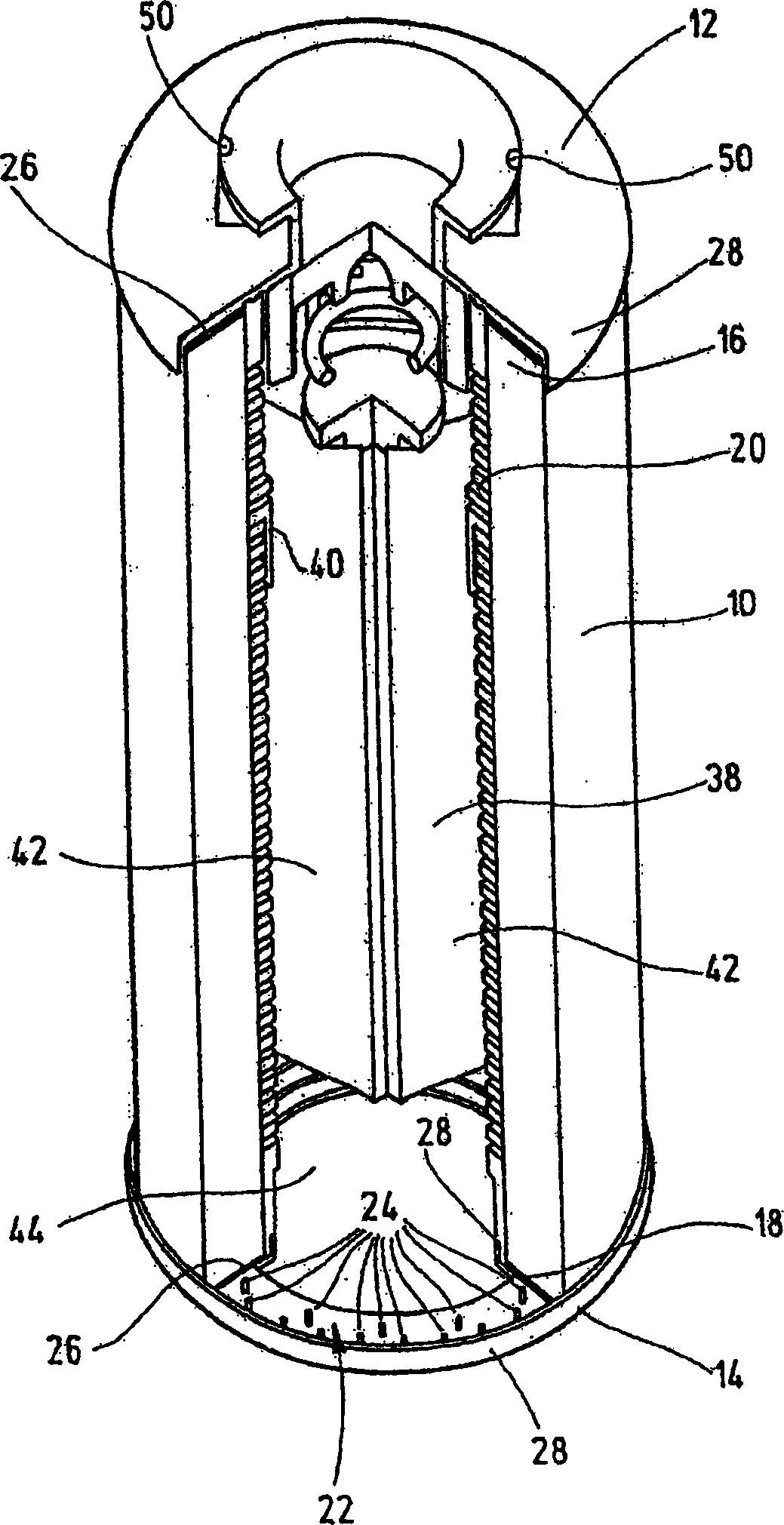

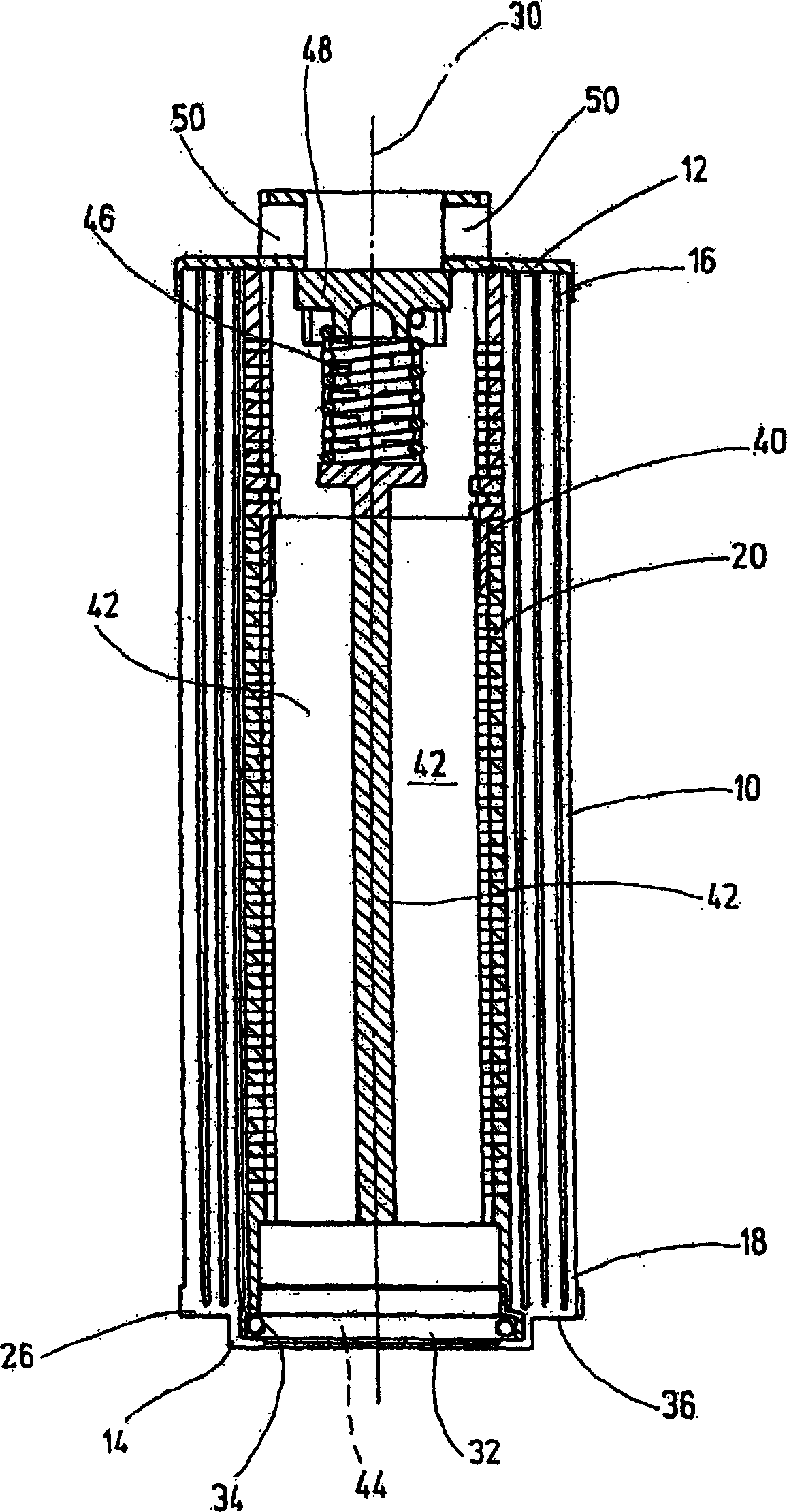

[0017] The filter unit according to the invention has a filter medium 10 which extends between two end caps 12 , 14 which are respectively connected to an assignable end region 16 , 18 of the filter medium 10 which also has an inner circumference. The sides are supported on a support tube 20 . exist figure 1 Seen in the direction of view of , the lower end cap 14 has a contacting device, indicated as a whole by 22 , for conducting away electrostatic charges that arise especially during operation of the filter unit.

[0018] The contacting device 22 consists of individual electrically conductive contact elements, in particular in the form of individual contact pins 24 , which penetrate between the end cap 14 of the filter medium 10 and the received end region 18 to form a The adhesive layer 26 of the insulating layer is thus in conductive contact with the filter medium 10 . The contact pins 24 thus pass through the adhesive layer 26 and they also stand vertically on the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com