Multistage pulses enhanced perforation equpment in use for oil and gas well

A technology of oil and gas wells and pulses, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of delaying precious time for oil production, occupying manpower and material resources, and limited space for perforating guns, etc. The effect of loading time, improving joint making ability, saving manpower and construction equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

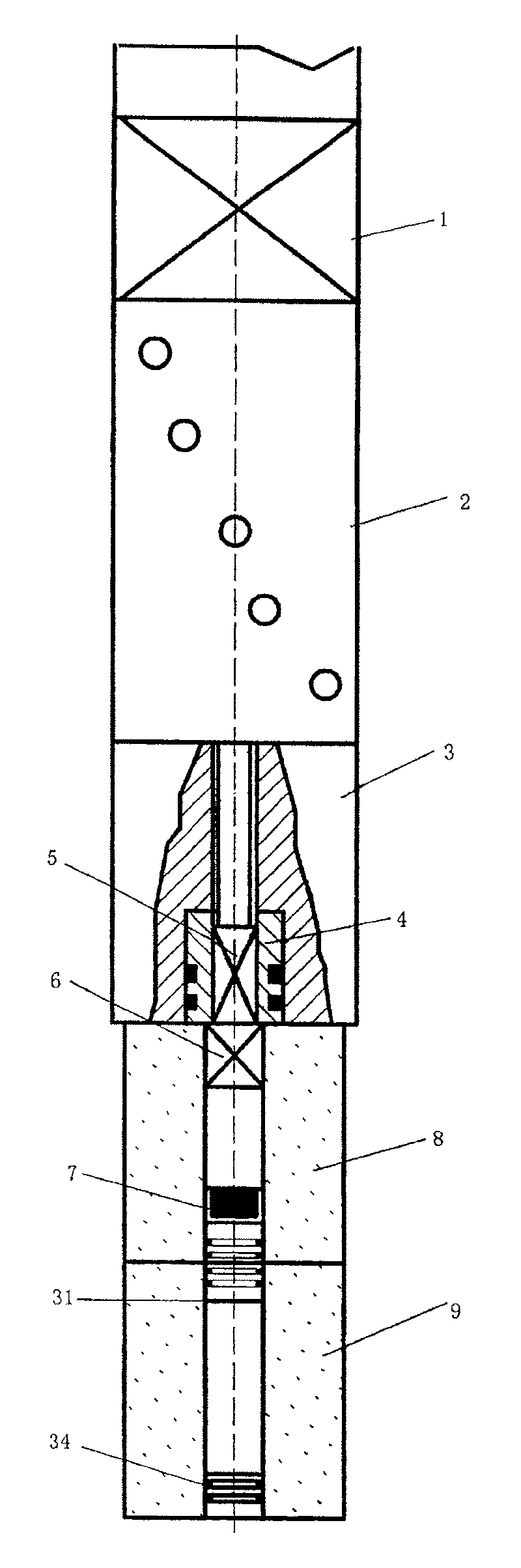

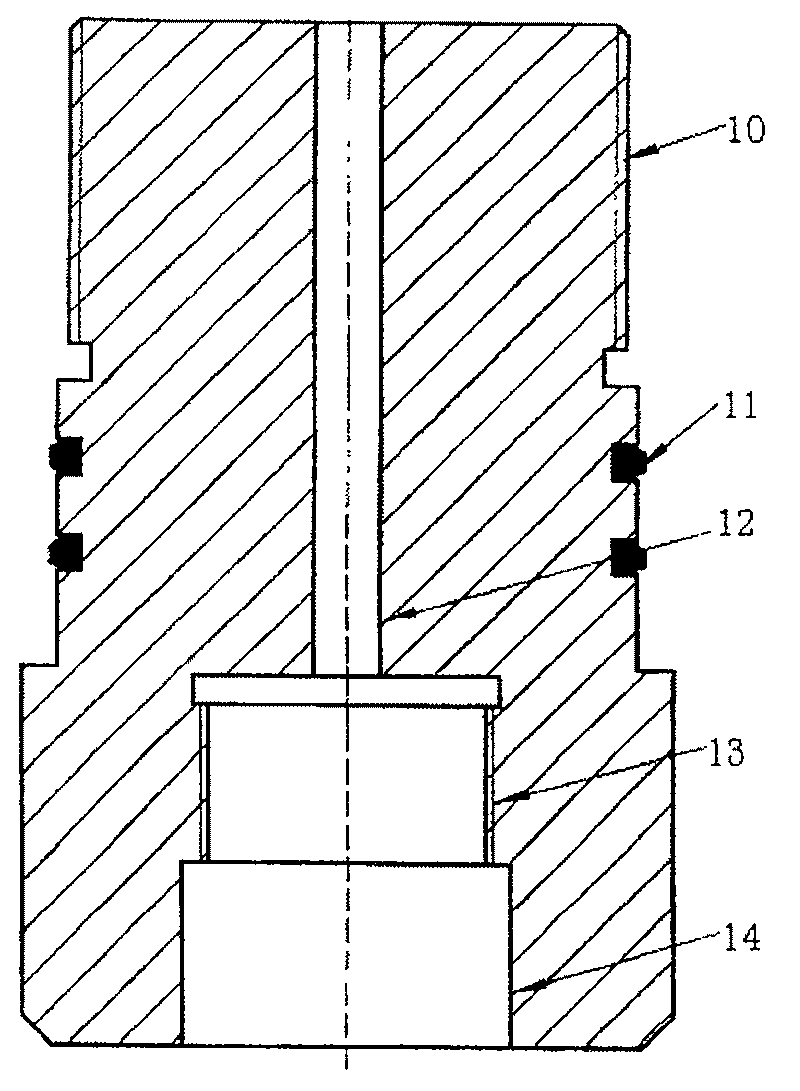

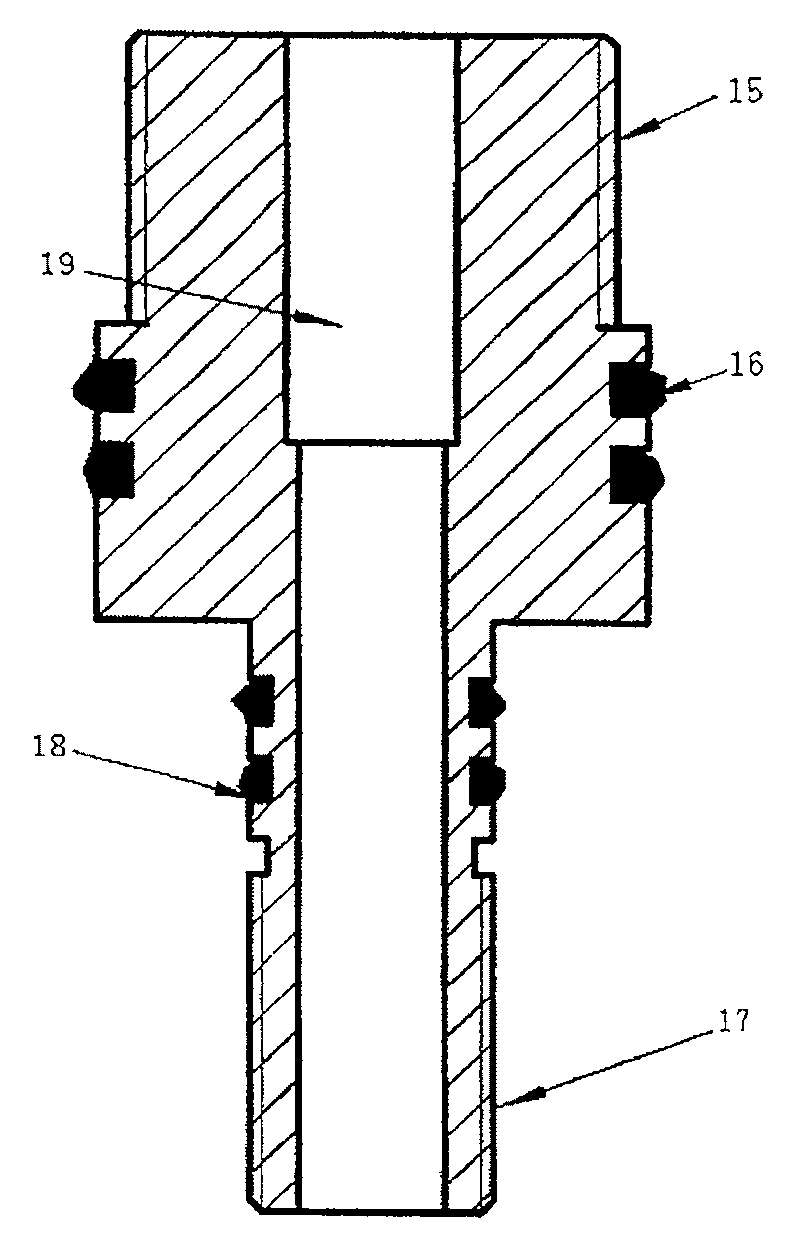

[0020] according to figure 1 As shown, the construction pipe string carried out by the preferred embodiment of the present invention mainly includes a sand-proof impact detonator 1, a synergistic perforating gun 2, a synergistic gun tail 3 and a connecting piece 4, a booster tube 5, and a partition delay Igniter 6, ignition powder column 7, secondary synergistic propellant powder 8, tertiary synergistic propellant powder 9, wire connector 31, sealing plug 33. The anti-sand percussion detonator 1 is a standard product, which can be any percussion detonator used in the tubing transmission perforation with sand control function in various oilfields, and the pressure detonator can also be used in deviated wells. The enhanced perforating gun 2 is a standard product, which can be any type of enhanced perforation with blind holes or withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com