Aptamer and upconversion nanoparticle modified copolymer as well as synthesis and application thereof

A technology of nanoparticles and copolymers, which is applied in the direction of drug combinations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as limitations of in vivo applications, and achieve the effect of avoiding toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of Aptamer and upconversion nanoparticles modified poly(2-hydroxyethyl methacrylate)-cinnamic acid graft copolymer

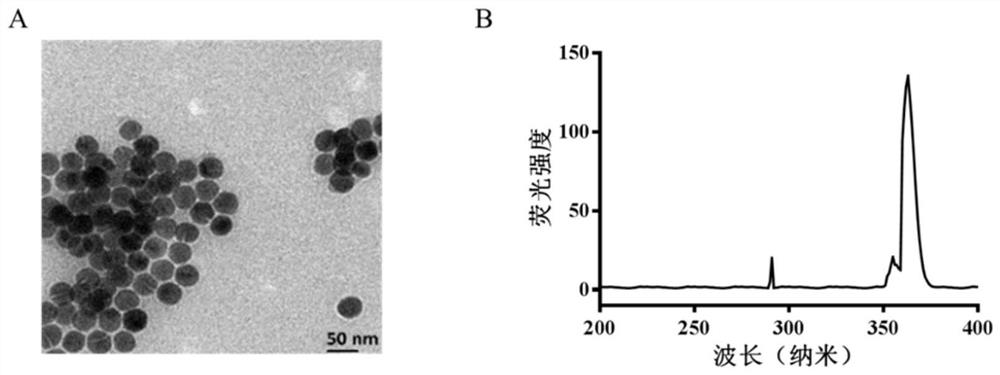

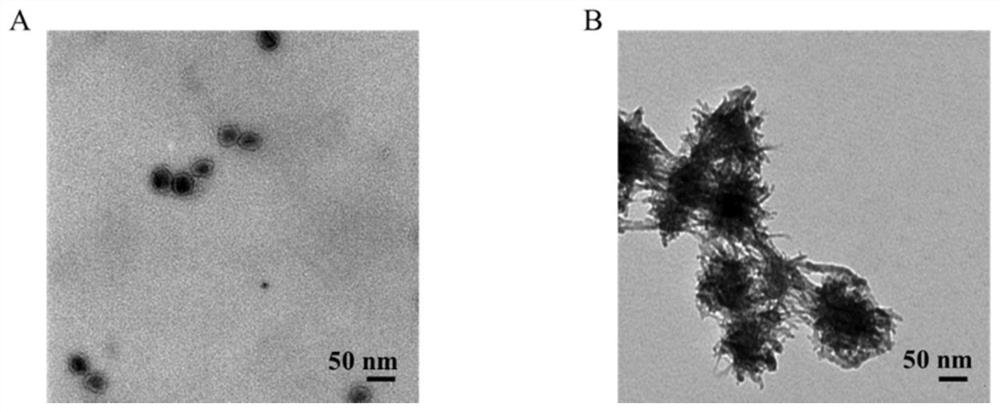

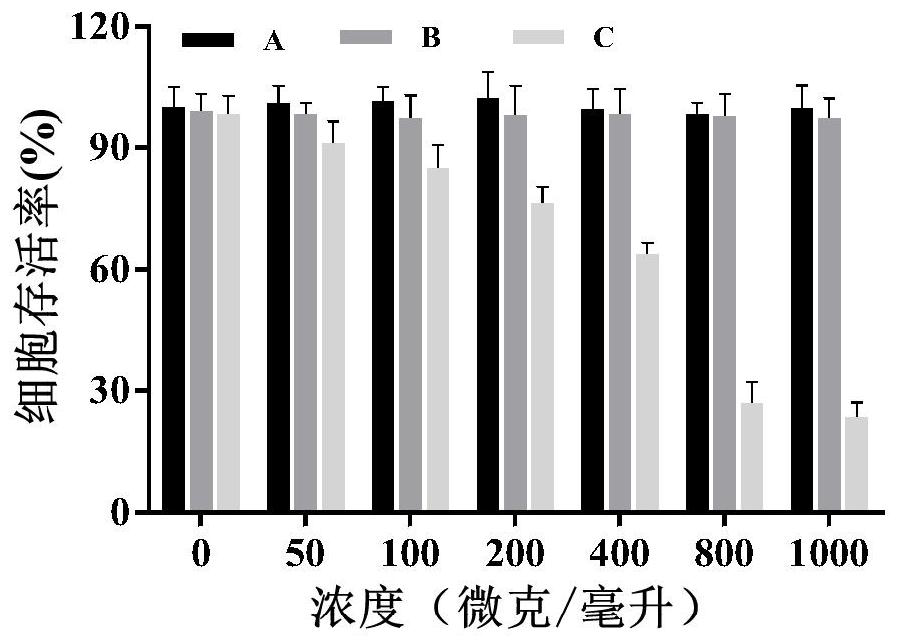

[0032] 1. Synthesis and amination modification of upconversion nanoparticle UCNP: using rare earth chloride as raw material, upconversion nanoparticle (UCNP) was prepared by solvothermal method: 1 mmol of rare earth chloride salt RECl3 6H2O (RE=79.5%Y, 20% Yb, 0.5% Tm), 15ml octadecene and 6ml oleic acid (OA) were placed in a 100ml three-necked flask, and under the protection of argon, the temperature was raised to 160°C and kept for 40min to ensure that the solid matter was completely dissolved. Then the temperature of the system was naturally cooled to room temperature, and 10 mL of anhydrous methanol mixture dissolved with 0.15 g of ammonium fluoride and 0.1 g of sodium hydroxide was slowly added dropwise into a three-necked flask, and reacted at 50 ° C for 30 min under vigorous stirring conditions. Then, under argon protection, ...

Embodiment 2

[0037] Example 2: Preparation of Aptamer and upconversion nanoparticles modified poly(2-hydroxyethyl methacrylate)-cinnamic acid graft copolymer

[0038] 1. Synthesis and amination modification of upconversion nanoparticle UCNP: using rare earth chloride as raw material, upconversion nanoparticle (UCNP) was prepared by solvothermal method: 1 mmol of rare earth chloride salt RECl3 6H2O (RE=79.5%Y, 20% Yb, 0.5% Tm), 15ml octadecene and 6ml oleic acid (OA) were placed in a 100ml three-necked flask, and under the protection of argon, the temperature was raised to 160°C and kept for 40min to ensure that the solid matter was completely dissolved. Then the temperature of the system was naturally cooled to room temperature, and 10 mL of anhydrous methanol mixture dissolved with 0.15 g of ammonium fluoride and 0.1 g of sodium hydroxide was slowly added dropwise into a three-necked flask, and reacted at 50 ° C for 30 min under vigorous stirring conditions. Then, under argon protection, ...

Embodiment 3

[0043] Example 3: Preparation of Aptamer and upconversion nanoparticles modified poly(2-hydroxyethyl methacrylate)-cinnamic acid graft copolymer

[0044]1. Synthesis and amination modification of upconversion nanoparticle UCNP: using rare earth chloride as raw material, upconversion nanoparticle (UCNP) was prepared by solvothermal method: 1 mmol of rare earth chloride salt RECl3 6H2O (RE=79.5%Y, 20% Yb, 0.5% Tm), 15ml octadecene and 6ml oleic acid (OA) were placed in a 100ml three-necked flask, and under the protection of argon, the temperature was raised to 160°C and kept for 40min to ensure that the solid matter was completely dissolved. Then the temperature of the system was naturally cooled to room temperature, and 10 mL of anhydrous methanol mixture dissolved with 0.15 g of ammonium fluoride and 0.1 g of sodium hydroxide was slowly added dropwise into a three-necked flask, and reacted at 50 ° C for 30 min under vigorous stirring conditions. Then, under argon protection, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com