Quaternary grating material and preparation method and application thereof

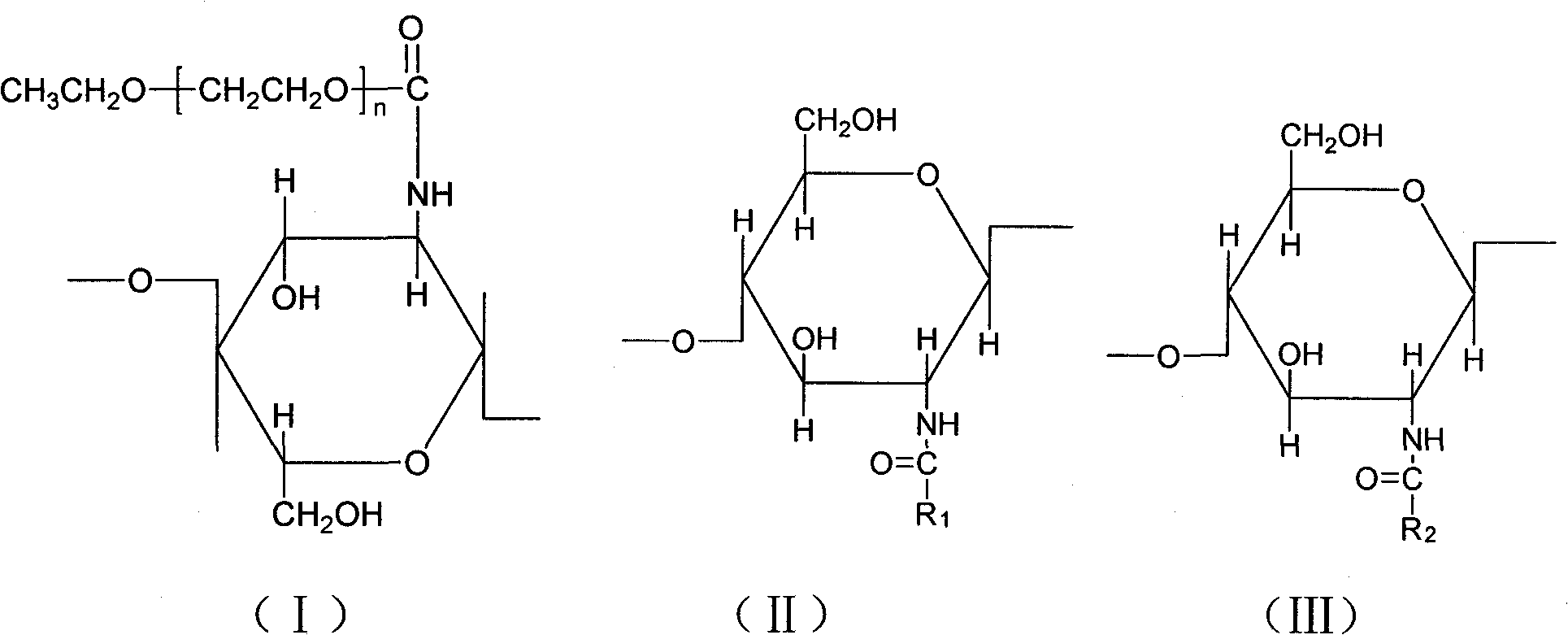

A technology of structural unit, chitosan oligosaccharide, applied in the field of compound and its synthesis, can solve the problems of insufficient lipophilicity, insufficient drug-carrying capacity, affecting cell transport function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 6 g of chitosan (average molecular weight 450,000) into 200 mL of 1.25 (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60 ° C, and adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid. Cellulase was added at a ratio of cellulase to chitosan of 0.5:100 (w / w). After controlling the reaction time for 24 hours, the reaction product was -1 Centrifuge for 10 minutes. The supernatant was pretreated with a 0.45 μm microporous membrane, fractionated with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with a certain molecular weight. By gel permeation chromatography, the average molecular weight of chitosan oligosaccharide was determined to be 1000Da.

[0023]Take by weighing 1.0g of chitosan oligosaccharide obtained above, add 160mL double-distilled water and stir to dissolve; in addition, weigh end carboxylated poly(lactic acid-glycolic acid) (mole...

Embodiment 2

[0027] Add 6 g of chitosan (average molecular weight 450,000) into 200 mL of 1.25 (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60 ° C, and adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid. Cellulase was added at a ratio of cellulase to chitosan of 0.5:100 (w / w). After controlling the reaction time for 18 hours, the reaction product was -1 Centrifuge for 10 minutes. The supernatant was pretreated with a 0.45 μm microporous membrane, fractionated with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with a certain molecular weight. By gel permeation chromatography, the average molecular weight of chitosan oligosaccharide was determined to be 5000Da.

[0028] Take by weighing 1.0g of chitosan oligosaccharide obtained above, add 160mL double-distilled water and stir to dissolve; in addition, take carboxylated poly(lactic acid-glycolic acid) (molecula...

Embodiment 3

[0032] Add 6 g of chitosan (average molecular weight 450,000) into 200 mL of 1.25 (v / v) hydrochloric acid aqueous solution, stir and dissolve at 55-60 ° C, and adjust the pH to 5.0 with dilute ammonia water or dilute hydrochloric acid. Cellulase was added at a ratio of cellulase to chitosan of 0.5:100 (w / w). After controlling the reaction time for 18 hours, the reaction product was -1 Centrifuge for 10 minutes. The supernatant was pretreated with a 0.45 μm microporous membrane, fractionated with ultrafiltration membranes of different molecular weights, and the ultrafiltrate was freeze-dried to obtain chitosan oligosaccharides with a certain molecular weight. By gel permeation chromatography, the average molecular weight of chitosan oligosaccharide was determined to be 5000Da.

[0033] Take by weighing 1.0g of chitosan oligosaccharide obtained above, add 160mL double-distilled water and stir to dissolve; in addition, take carboxylated poly(lactic acid-glycolic acid) (molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com