Tower for a wind turbine, prefabricated metal wall part for use in tower for a wind turbine and method for constructing a tower for a wind turbine

A technology for wind turbines, metal walls, applied in the field of towers for wind turbines, prefabricated metal wall parts used in towers for wind turbines, and the construction of towers for wind turbines, which can solve the problem that concrete towers are not an economical solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

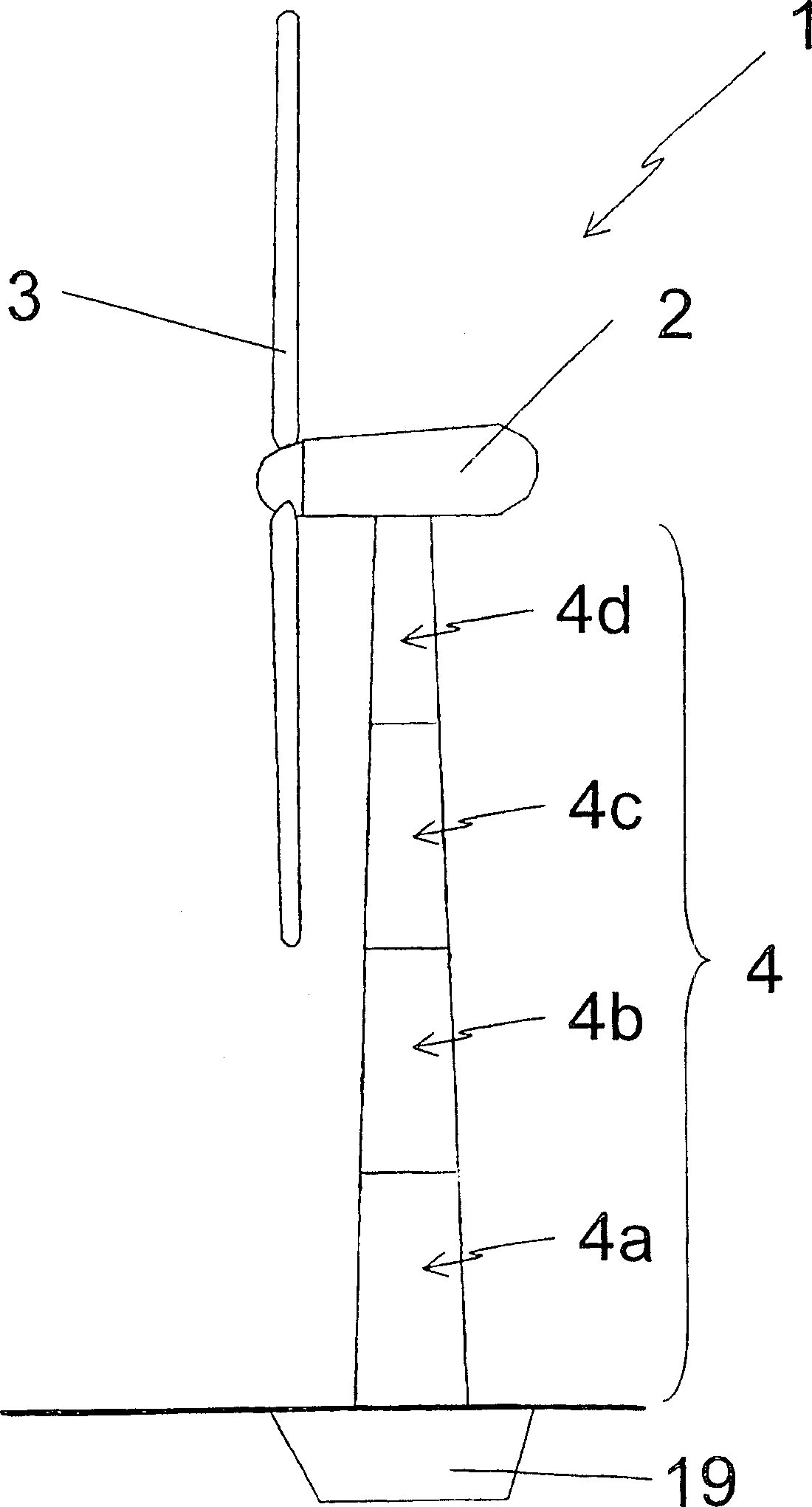

[0038] figure 1 A wind turbine 1 is schematically shown in . The wind turbine 1 comprises a generator 2, a rotor 3 and a tower 4 on which the combination of generator and rotor is mounted. The tower 4 has an outer surface forming the outside of the tower 4 and an inner surface forming the inside of the tower. The tower consists of four tower sections 4a-4d. The wind turbine is arranged on a foundation 19 .

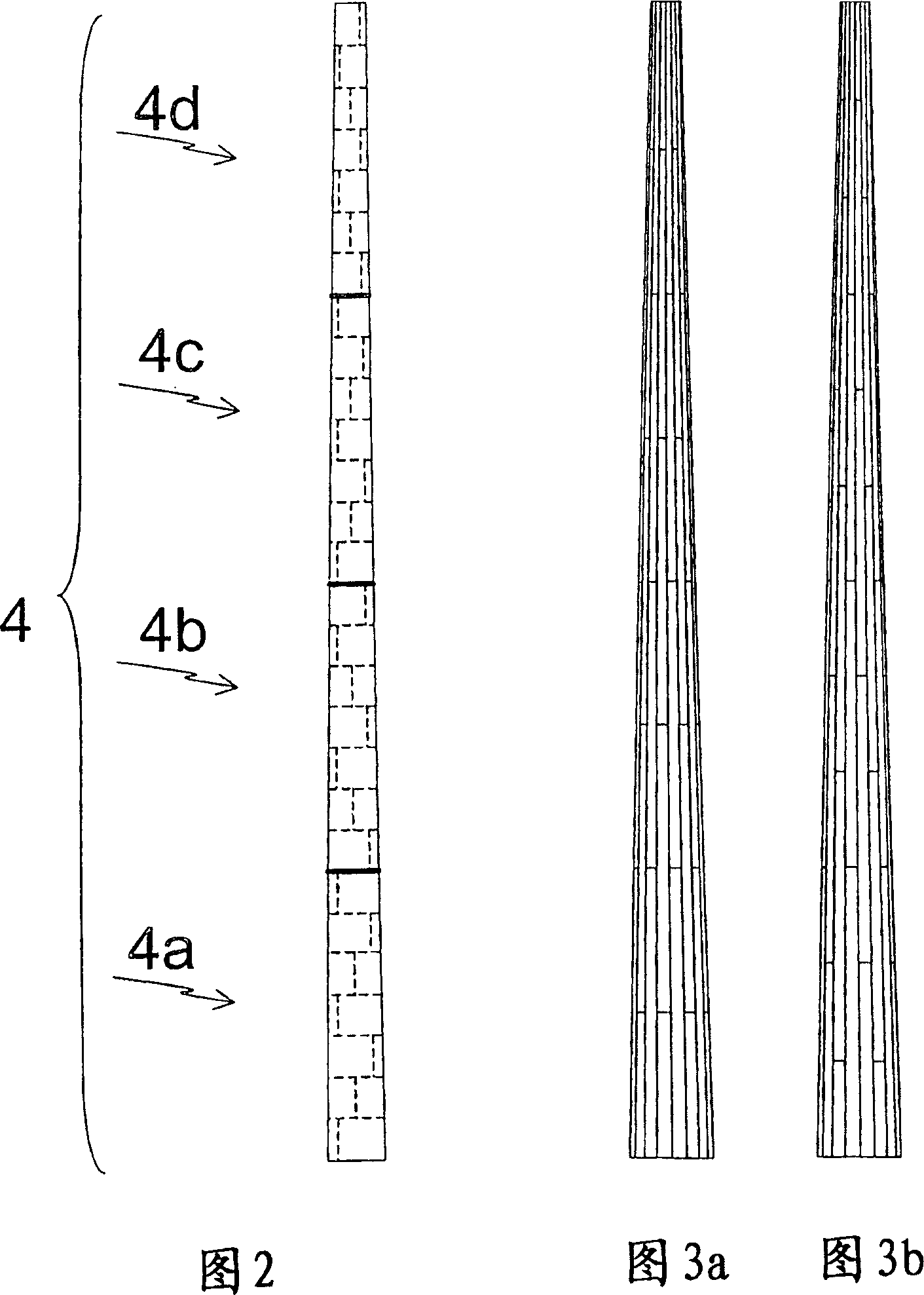

[0039] In Fig. 2 a tower 4 for a wind turbine according to prior art is shown. The tower segments 4a, 4b, 4c, 4d are mounted on top of each other. These tower sections are fabricated off site and connected by horizontal flanges and large bolts and nuts. These flanges are indicated by thick horizontal lines between the tower segments. The tower sections are made of curved plates, which are welded together horizontally and vertically. These welds, indicated by dashed lines, are known to be a possible source of fatigue fracture, especially horizontal welds. For a towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com