Filter element for dust collector

A technology of vacuum cleaners and filter elements, which is applied in the direction of suction filters, etc., and can solve problems such as affecting air permeability and difficulty in cleaning foreign substances such as dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

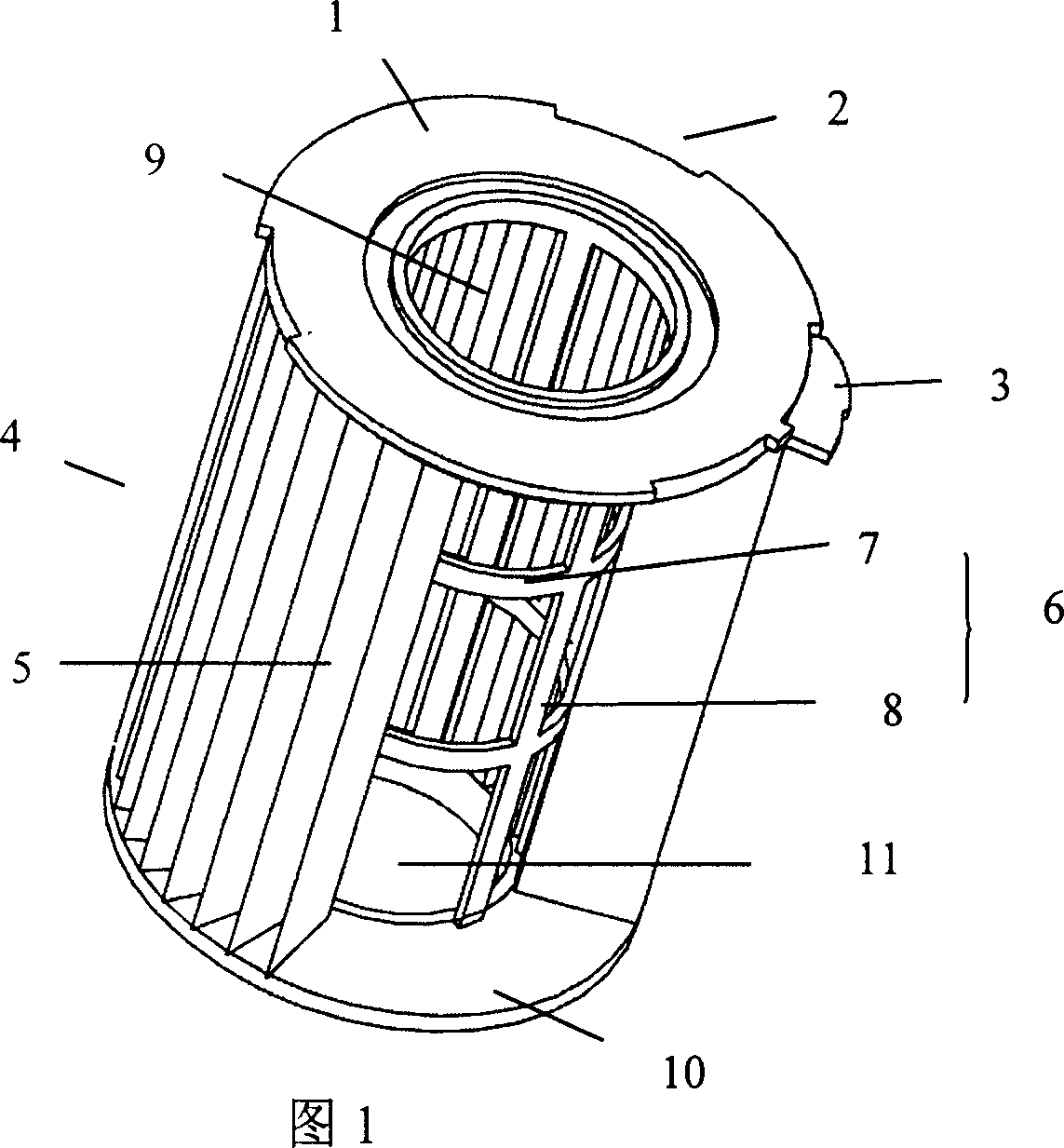

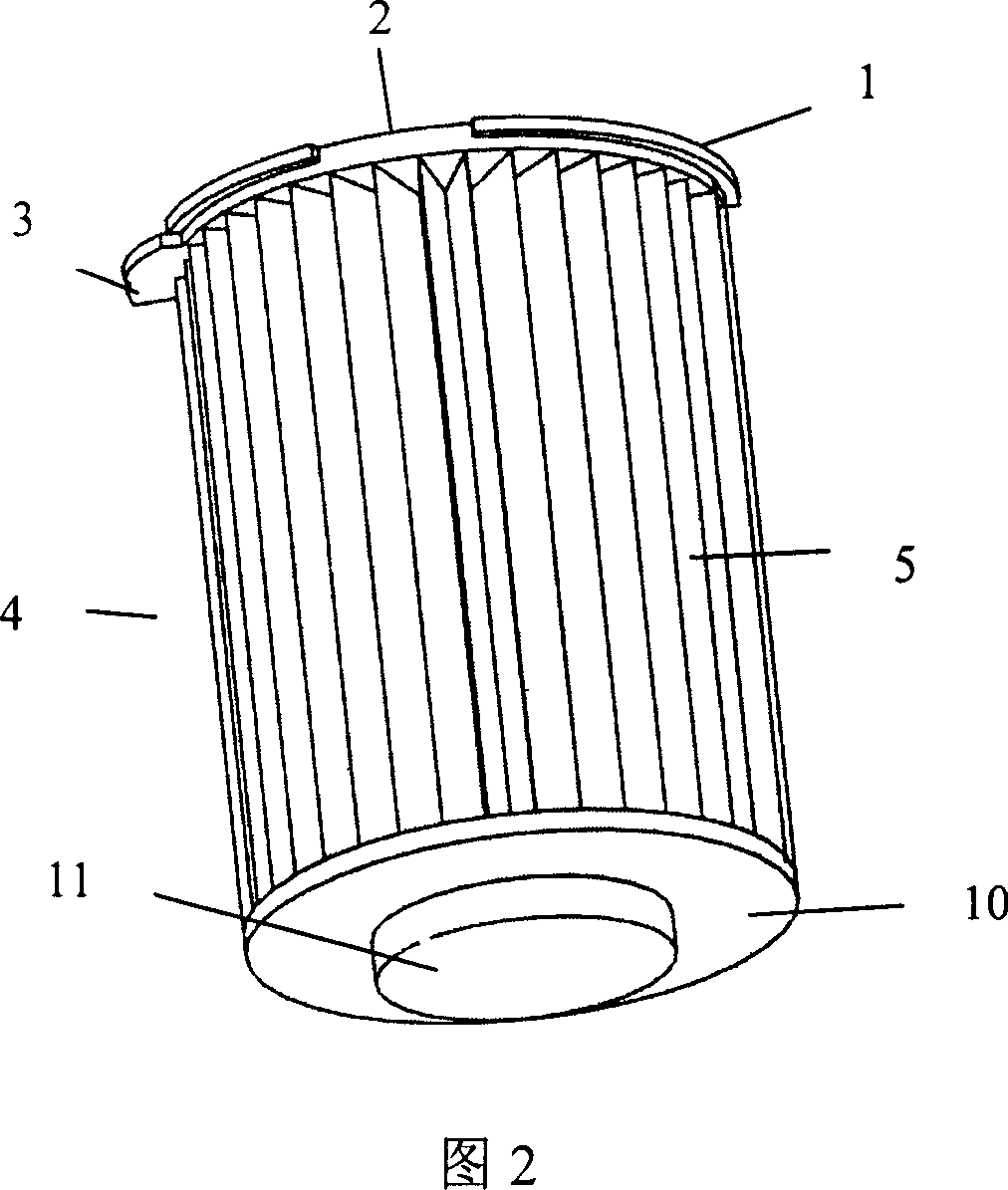

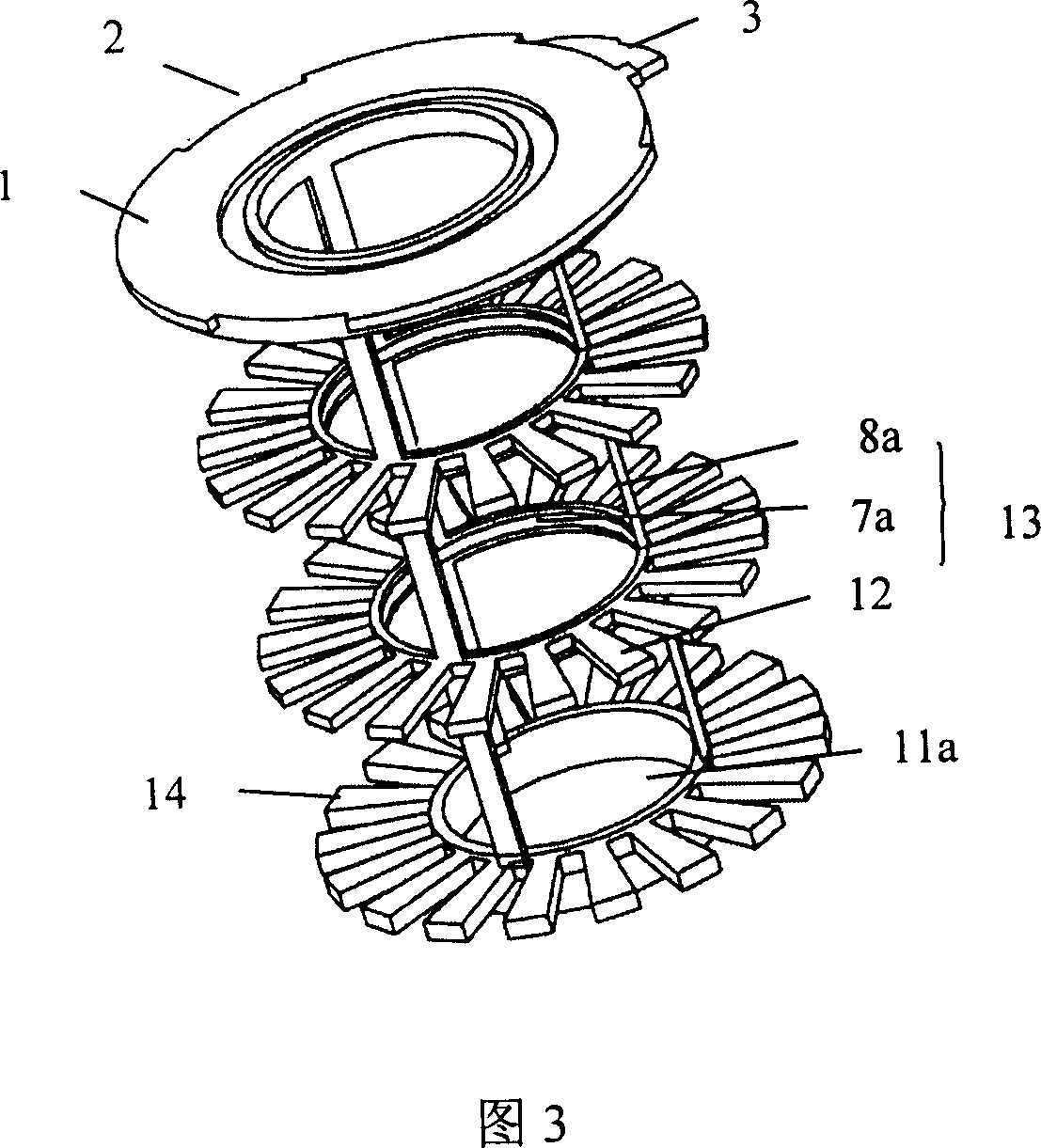

[0032] A vacuum cleaner filter element, comprising a concentric upper bracket 1 with a central hole at both ends of the filter element and a base frame plate 14 with a bottom groove 11a, and a hoop 7a is arranged between the upper bracket 1 and the base frame plate 14 The hollow frame 13 integrated with the support rod 8a is fixed to the periphery of the hollow frame 13 between the bottom surface of the upper bracket 1 (not shown) and the circular base, and is fixed to a cylindrical shape with folds of equal amplitude. The filter paper tube 4a; the folds that are continuously folded back on the cylindrical filter paper tube 4a are trapezoidal folds 15 with the top edge inward and the bottom edge outward; the base with the bottom groove 11a forms the top edge inward and the bottom edge outward The outer base frame plate 14; the outer periphery of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com