Alternating current synchronous motor based on three-phase rotary transformer technology, alternating current wound rotor motor and arrangements for speed regulation

A technology of AC synchronous motors and wound rotor motors, applied in AC motor control, transformers, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

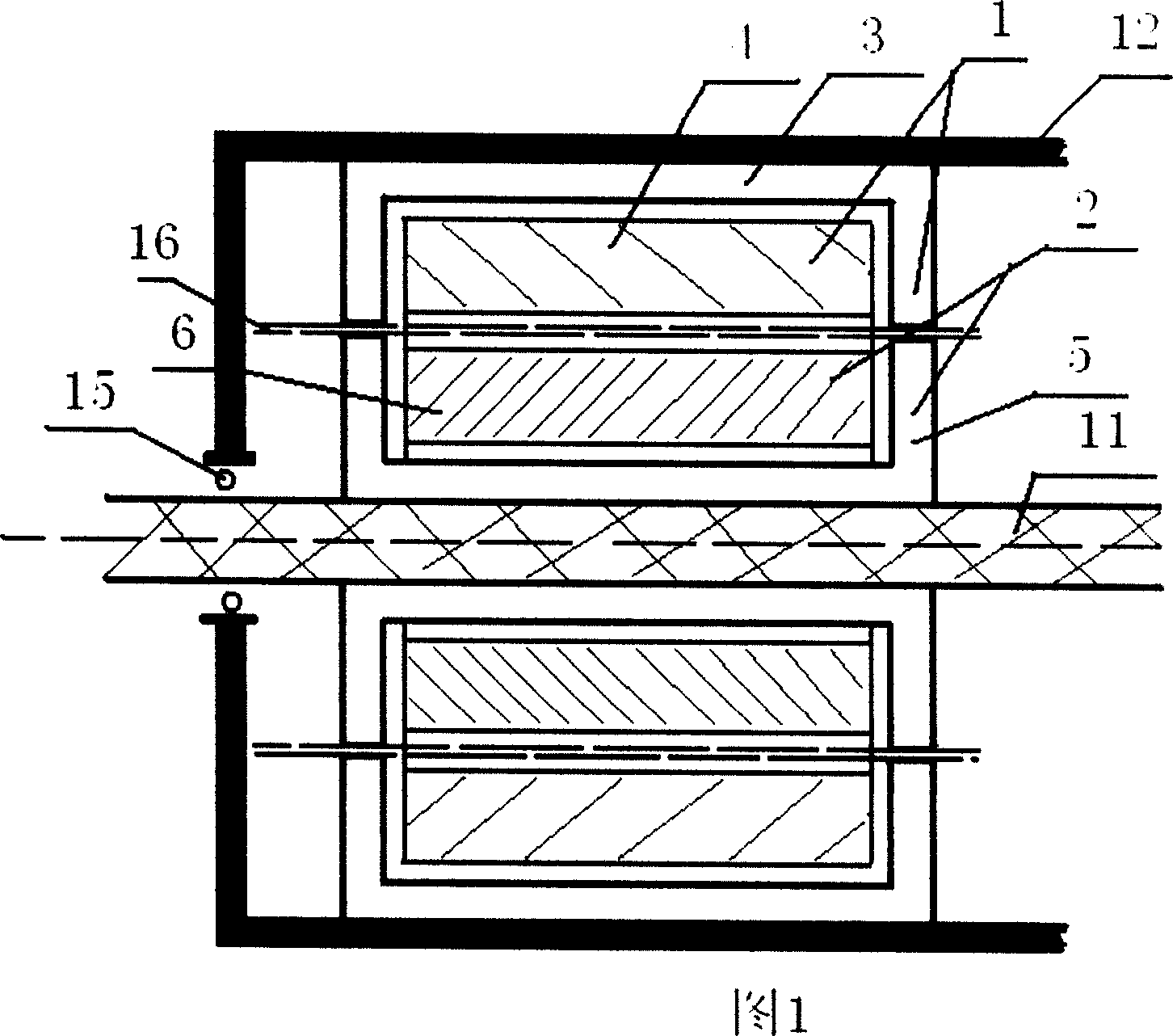

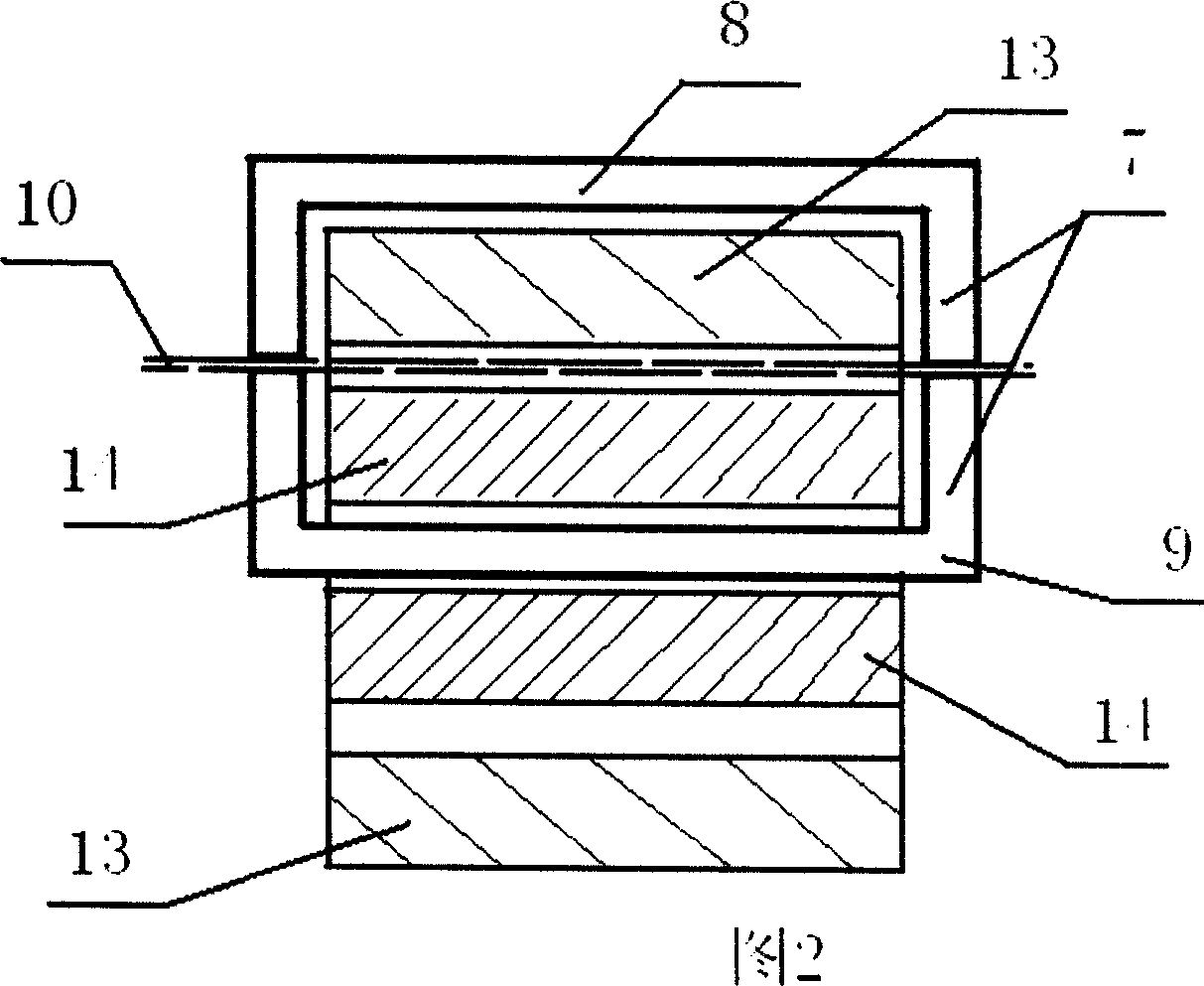

[0027] See Figure 1 and Figure 2, each single-phase rotary transformer is composed of a stator part (stationary) 1 and a rotor part (rotating) 2, the stator part 1 is composed of a stator core 3 and a stator winding 4, and the rotor part 2 is composed of a rotor core 5 and rotor winding 6. Its structure and principle are as follows: the closed iron core 7, primary winding 13 and secondary winding 14 of an ordinary single-phase transformer are divided into two parts in the form of an air gap 10, and one part is the primary winding 13 and the core 8. Part of it is the secondary winding 14 and the iron core 9. Under the premise of maintaining the working principle of the transformer, it is deformed according to the form of the motor stator and rotor. The iron core 9 is transformed into the rotor core 5, the secondary winding 14 is transformed into the rotor winding 6, and the iron core 8 is transformed into The stator core 3, the primary winding 13 is transformed into the stator w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com