Ball-shape compressor and expansion compressor capable of realizing multi-stage compression

A technology of spherical compressors and expansion compressors, applied in the field of compressors, can solve problems such as inability to achieve multi-stage compression or multi-stage compression, expansion, noise, vibration, cost and space increase, reliability and efficiency decline, etc. Achieve the effect of reducing working fluid leakage, compact structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] 1. The first embodiment

[0085] The first embodiment is adopted as the first structural form of the present invention.

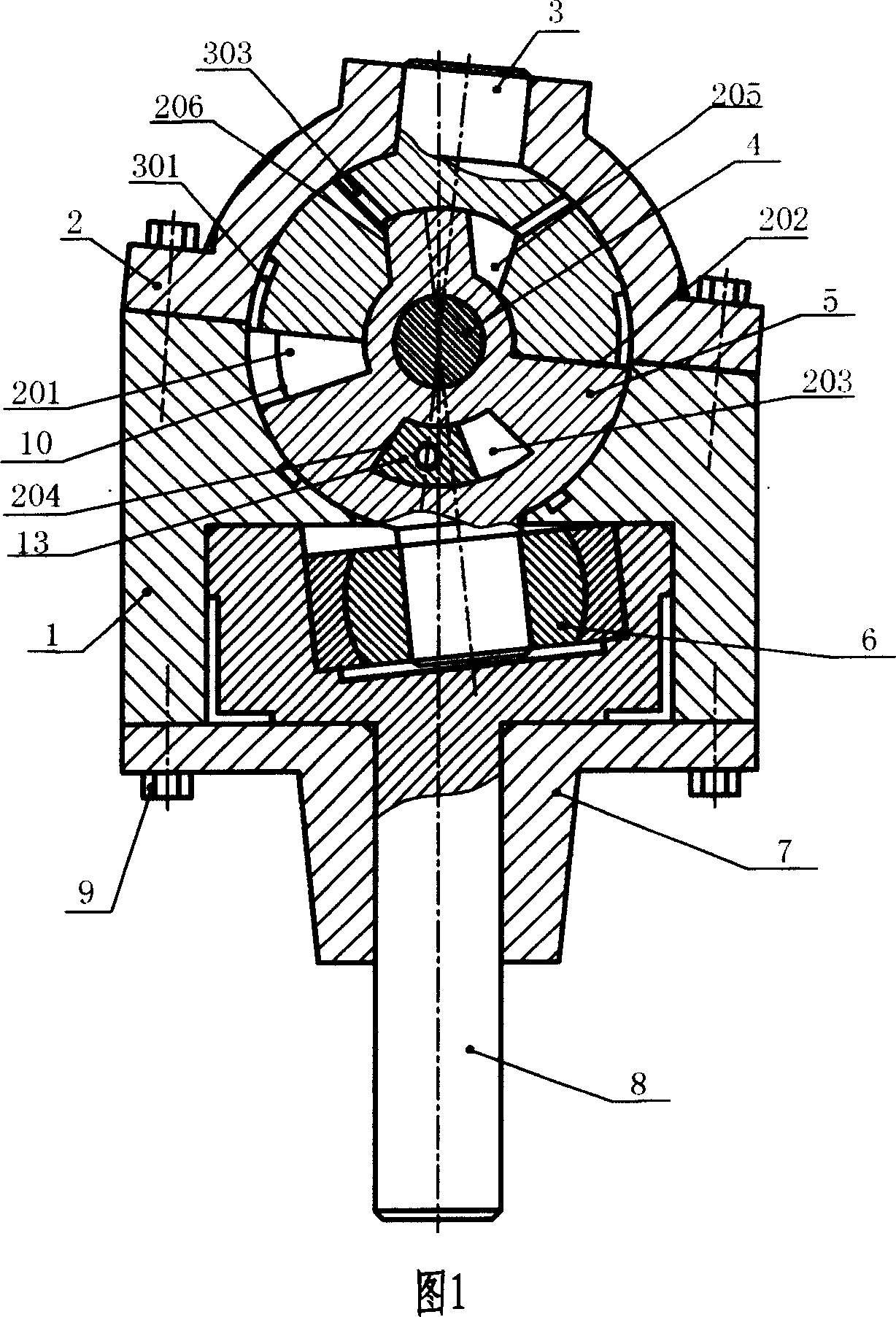

[0086] Fig. 1 is a structural sectional view of the first embodiment, the compressor includes cylinder head 2, cylinder body 1, piston 3, turntable 5, center pin 4, main shaft 8, main shaft support 7 and other parts, cylinder body 1 and cylinder head 2 Connected by connecting screws 9 to form a spherical inner cavity, the piston 3 has a spherical top surface, a piston shaft protrudes from the center of the spherical top surface, the lower part of the piston 3 has a piston pin seat, and the cylinder head 2 has a piston shaft hole corresponding to the piston shaft. It can be freely rotated in the shaft hole of the piston, and the spherical top surface of the piston 3 fits the above-mentioned spherical inner cavity; the upper part of the turntable 5 corresponds to a turntable pin seat, and the center of the lower end surface of the turntable 5 protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com